Situation

Roland is the manager of process cheese products for a food company. Every day at the operations meeting he gives the average moisture content for each product by shift. Moisture specifications are tightly regulated and the company would like to control the moisture content with an average reading to be as high as possible without going outside specifications. To cut costs, the plant manager asked Roland to investigate increasing the average moisture content of Product LF25, a low-fat process cheese spread. Roland asked the quality manager, Christine, to assist in the investigation.

Available data

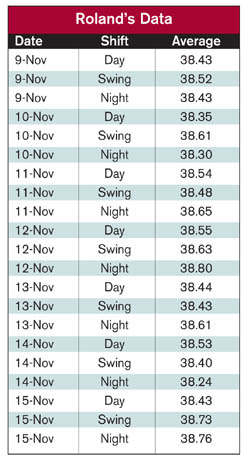

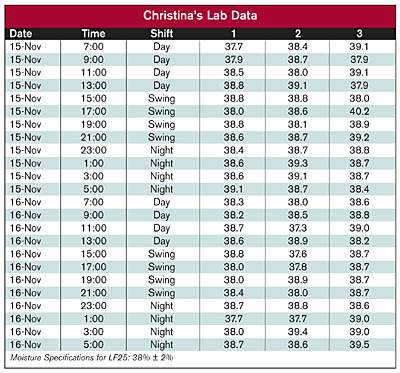

Roland did an analysis using the data for average moisture content of LF25 taken from production reports of each shift for the past week. These values appear in the table, "Roland's Data." Christine focused on moisture data of LF25 taken during production. Lab personnel record moisture readings every 2 hours for three containers of LF25. Data for the past 2 days are given in the table, "Christine's Lab Data." Specifications for moisture content of LF25 are 38% ± 2%.

Questions

Using the shift averages from Roland's production reports, is the process predictable?

What can be said about the predictability of moisture content from the lab data provided by Christine? Is this result consistent with that from Roland?

Based on the analysis of the lab data, what recommendation should Christine propose regarding an increase in the average moisture content of LF25?

Based on the analysis of the shift averages, what recommendation should Roland propose with respect to increasing the average moisture content of LF25?

Answers to November Brain Teaser

In their job as operators of a machine that makes adhesive bandages, Terry and Marla experience frequent machine jams that can only be fixed by maintenance. Sometimes maintenance personnel are unavailable, which leads to excessive lost time and high scrap for adhesive bandages. After keeping a log of the machine jams for 2 weeks, Terry and Marla participate in a trial where they fix some of the machine jams.

Q: How much lost time incurred during the 2 weeks prior to the trial period?

A: A total of 928 minutes, or 15 hours and 28 minutes, of lost time incurred for this machine during the 2 weeks prior to the trial. This amounts to two shifts of production.

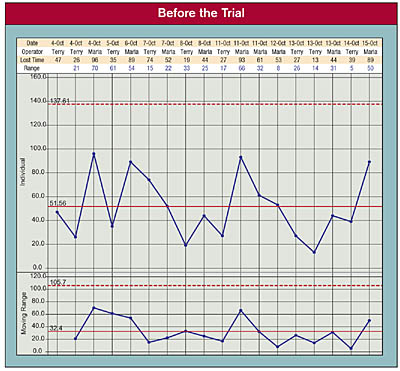

Q: Is the time lost for the jams during this period predictable?

A: During this period, the process is predictable with an average of 51.6 minutes lost per jam. Actual time lost can go as high as 133.3 minutes-more than 2 hours-for a given, single jam based on the routine way the process of fixing jams works. See the chart, "Before the Trial."

Q: How much lost time incurred during the 2-week trial? Is this lost time predictable?

A: A total of 315 minutes, or 5 hours and 15 minutes, of lost time incurred during the trial period. This is a 66% reduction in lost time during the 2 weeks prior to the trial. See the chart, "The Trial."

Q: Is the evidence sufficient to recommend that Terry and Marla fix some types of jams rather than waiting on maintenance?

A: There has been a dramatic reduction in lost time for this adhesive bandage machine as shown by the process behavior chart. An analysis of the lost time during the 2-week trial with Terry and Marla shows an unpredictable process. Performing the analysis using the median moving range ensures that exceptions have the best chance of being seen. Two exceptions are highlighted, both of which are associated with machine jams that require maintenance expertise. For the types of jams that Terry and Marla can fix, the average lost time is 16.6 minutes. This is a definite improvement and a compelling reason to have Terry and Marla continue to fix certain machine jams.