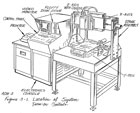

Note how technology has changed throughout the years. The 1980 system has a 5-inch text-only computer monitor, while the 2008 system has dual flat-panel LCDs with color graphics. What can’t be seen are the improvements in performance and capabilities. Source: Optical Gaging Products Inc.

As of 2008, tens of thousands of video measuring machines are in broad use by manufacturers around the world. It has been just more than 30 years since the first video measuring systems were developed in the United States for dimensional measurement applications in manufacturing quality control.

In the beginning, both product and market definition were headed in several directions. It was inspection or measurement; online or offline; fixed magnification or multiple magnifications; and adapt existing products or create completely new products. During that time, the associated technologies were evolving at a rapid pace-new cameras and computers enabled high-speed image processing necessary for good quality decisions.

Today video measuring machines represent more than $200 million of business per year.

New Technology

New technology is so pervasive, it is often taken for granted. Cell phones take megapixel pictures. When the video inspection industry began in the late 1970s, solid-state cameras were just being introduced. Most electronic imaging used vidicon tubes, bulky vacuum tubes with associated high voltage power supplies.And think about computers. Per-sonal computers and Windows were still years away from being introduced.

During those 30 years, video measuring technology evolved in parallel with advances in manufacturing technologies. Today parts are designed in computer-aided design (CAD) software and machined on five-axis machine tools with tolerances that are tighter than ever.

Noncontact vision measurement technology has kept up. In fact, one could argue that measurement technology enables the products of today. More than 100 companies have been players in the video inspection business during those 30 years-only a handful for the entire period. A review of that history can be enlightening.

The quad surface light from the 1980s uses four fiber optic illuminators and halogen light sources. Source: Optical Gaging Products

From Optical Comparators to Video

Optical comparators have been in use since the 1930s. Magnified projections of shadows cast by flat parts are compared to chart gages on round screens of 30-inches or more in diameter.In the 1970s those inspections and measurements were manual, and the quality of the outcome depended on the skill of the operator. One track of product development adapted the optical comparator, replacing the large round screen with a video monitor image from a camera. These comparator-based video systems measured in 2-D-parts such as PC artwork, circuit boards and broached sheet metal-performing profile imaging as with an optical comparator. Because the camera signal was electronic, it could be analyzed with image processing software and automated so every system operator could get the same results.

In the late 1970s, the first video measurement systems were adaptations of optical comparators. The Jones & Lamson Metric Eye and the EMR Photoelectric Comp-Gage used image-dissector tubes to derive images for 2-D measurements. The EyeCom system from Spatial Data Systems used software algorithms in the BASIC language to determine edges in images.

A different path to product development was purpose-built video measuring systems not based on existing platforms. These systems were forerunners of what most are familiar with today.

In 1977, View Engineering of Chatsworth, CA, introduced the RB-1, the world’s first three-axis, automatic video measuring system. Unlike other vision systems of the time, RB-1 was an automated measurement system with motorized XYZ stages, a control terminal with built in video monitor and metrology software.

EMR introduced the Comp-Gage Qualitizer, which used a solid-state camera along with a X-Y positioning table.

Yet a different product design was the Boice Vista system from Mechanical Technology Inc., which integrated a video system into a standard coordinate measuring machine (CMM). The system compared measured features to preprogrammed part-print nominal dimensions and tolerances.

The white LEDs in the modern ring light are seen reflected in the stage glass. Source: Optical Gaging Products Inc.

Into the 80s

Product introductions in 1980 continued along two divergent implementations of video measuring technology. The original Jones & Lamson VIVIC was an optical comparator mated to an automatic optical micrometer.A different approach was shown when Optical Gaging Products (OGP) introduced the Vidicom Qualifier 863, the first modern video inspection system to use a solid-state CID camera and grayscale image processing. Its dual-magnification optical system was fully telecentric for undistorted imaging. It used a Hewlett Packard model 85 computer with 8 kilobytes of computer memory. The system was a purpose-built video measurement system, not an adaptation of an optical comparator.

A year later, Ram Optical Instrumentation (ROI) developed the Optical Video Probe, an optical assembly that became the basis for the family of video machines they developed since that time.

In the mid-80s video measuring systems that worked at high magnifications through the use of microscope objectives were introduced. The use of a microscope turret allowed for rapid magnification changes while the feature of interest remained in the field of view.

Hand-drawn sketches from 1980 contrast with the prevalence of CAD illustrations common today. Source: View Engineering Inc.

A Fragmented Industry

The early vision industry was fragmented with companies formed to serve specific vision applications. Laura Conigliaro of Prudential-Bache Securities said in a speech at the Vision ’85 conference, “Each company has a slightly different perspective and maybe slightly different applications.”Essentially proving her point, on January 15, 1985, Eastman Kodak, on the in-process inspection side of the industry, launched the 100-employee Videk machine vision division based on the company’s experience with systems it had installed on its own production lines. Kodak estimated at the time they would be competing with 100 other machine vision companies. A March 1985 Machine and Tool Blue Book article on machine vision listed 75 companies as sources for machine vision systems.

In 1985 General Motors invested in five vision companies, giving the vision industry instant credibility. With this exposure, industry analysts were making dramatic projections about industry growth.

In that year OGP introduced the Q-SEE, a system designed to provide high accuracy measurements at a lower cost of ownership, with features such as six light sources. The system had a membrane touch panel in place of push buttons and toggle switches, popular at the time, which simplified programming in shop environments, while offering keyboard operation for those who preferred that method of system interaction.

Richard Hubach, president of View Engineering at the time, explained the company’s market positioning strategy in an April 1986 Manufacturing Systems article, “…We don’t have a particular industry that we service, but ours is a general purpose machine…”

This thinking signaled a departure from the more common application-specific market strategy for vision systems. Today both broad categories of vision technologies still exist-those that serve specific applications and those that are general purpose, accommodating a range of applications.

Even as video measurement systems were still evolving, in 1986 OGP introduced the IQ-2000, the first video measuring system to incorporate a graphics workstation, along with laser and touch probe sensors providing a common set of data about the measured part-what today is called multisensor measurement.

More competition developed in that product category. In 1988 Jones & Lamson introduced the Vertic system. The Matrix Videometrix Videoscope offered what they called “three-dimensional (3-D) vision,” which was explained as being similar to a coordinate measuring machine except that “while a CMM processes a point at a time, a 3-D vision system processes many points simultaneously.” Simultaneous measurement of many points at a time is a common characteristic, and benefit, of all video measurement systems.

Circa 1985, this system has a membrane touch panel, HP Thinkjet printer and dual 3½ inch floppy disk drives. Source: Optical Gaging Products Inc.

More Advances in the 1990s

By 1990 video measurement systems with motorized translation stages, multiple illuminators, solid-state cameras, and readily available computers were becoming popular among manufacturers.In 1991 the first benchtop video measuring system with a color camera and zoom lens was introduced. It signaled the availability of general purpose, user friendly, noncontact measurement in a system small enough to use anywhere in a manufacturing facility. Off-the-shelf systems signaled true commercialization of vision technology for dimensional metrology, further easing acceptance of the technology among manufacturers.

During the 1990s more companies entered the market with variations on the existing designs. Computer memory and disk drives increased in capacity and decreased in price while microprocessors upped their processing speeds. At the same time the performance of cameras and linear scales improved. Advances in light-emitting diodes saw them replacing lamps in surface and backlights. At the same time, video measuring systems were being adapted to changing requirements. By the late 90s stage travels on some systems extended to more than a meter to accommodate new applications such as flat panel displays.

On the software side, metrology software for video measuring systems added more functionality, the ability to import CAD files and output measurement results for statistical process control. Video systems with motorized stages, zoom lenses and programmable lighting moved from metrology labs into work cells, and closer to the production line. Video measurement technology was being used in more industries than the automotive industry envisioned in 1985, finding applications in consumer products, aerospace and even furniture.

Today, video measurement remains a critical aspect of operations in numerous manufacturing industries. The attraction of fast, repeatable measurements of parts without physical contact helps manufacturers keep their processes in control and their parts in specification.

Conigliaro of Prudential-Bache Securities got it half right when she said in an April 1986 article about the industry in Manufacturing Systems magazine, “Nearly all of these companies are still intending to stick it out…They believe that there is a significant and broad-based need for vision systems and that ultimately this will prevail.”

In reality, only a handful of those 75 to 100 companies from the 1980s still exist or remain in this line of business today. Yet, those video measuring system manufacturers that pioneered the industry and adapted to the latest available technologies to meet changing needs are satisfying “a significant and broad-based need for vision systems” envisioned more than 20 years ago.Q

Quality Online

To read more on video measurement, visit www.qualitymag.com to read these articles:- “Make the Switch to Video”

- Select the Right Video System”

- “Video is Versatile”

Major Technology Milestones by Decade

Video Measuring Systems and the 1980s

The 1980s were a period of significant activity and a number of innovations. Business analysts in the early 1980s considered video/vision measurement and inspection as a single category of optical/camera/electronic technologies in search of an application. The automobile industry was an early force interested in automating inspections and measurements. The numerous start-up companies of the time were each looking for “that big application” that would require hundreds of systems for years to come. It was an era of technologies looking for applications-not of existing customer needs in search of solutions.Defining Video Measurement Systems

Video measuring systems are sometimes known as optical coordinate measuring machines (CMMs). They are not the same as online vision inspection systems. Video measuring systems are stand-alone metrology systems, typically not integrated into the production line. Vision systems typically perform optical inspections of moving parts on the production line. To attain precision dimensional measurements, video measuring systems are designed to minimize environmental variables by measuring parts off-line.Video measuring systems range from manually controlled machines with digital readouts to fully programmable, CNC motorized machines that can measure parts without an operator being present. They can fit on a benchtop or be meters in size.