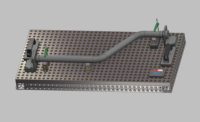

The redesigned modular tool is used in the remanufacturing and reconditioning process for multiple airplane cargo doors. Source: Paul W. Marino Gages Inc.

In only a few short years the concept of modular fixturing has piqued the interest of many in the varied and distinct worlds of quality. Manufacturing has never had so many work holding choices for use in inspection and assembly applications, for example.

The buzzwords-adaptable, adjustable, modular, reusable, reclaimable-describe just a few of the technology’s attributes, and much has been written about modular fixturing’s use in automotive applications.

Modular fixturing also lends itself to the aerospace tooling industry. For example, it could be used for the duplication and replacement of a set of tools used in a remanufacturing and reconditioning process for airplane parts. In this example, fixturing needs to support reconditioning operations for very large parts, such as the upper and lower cargo doors of an airplane. The traditional welded tools that have been dedicated to specific parts are replaced, and the challenge is to combine the series of seven distinct tools into one multi-part tool. One tool vs. seven separate tools provides a beneficial cost savings to the airplane manufacturer.

This traditional welded frame assembly fixture can only be used for one type of cargo door; the modular fixture can accommodate up to seven. Source: Paul W. Marino Gages Inc.

The size and weight of the airplane parts requires use of a robust fixturing system, with reusable components that can be used for a long period of time. Not only do the tools have to be reusable, they have to reconfigure easily-modified at any location in a short period of time using onsite machines and personnel.

Modular tooling is made to be ergonomic, have inherently high accuracy and be clean and free of foreign object debris, such as paint chips or small tools. The “go green” concept for reusability is a major focus, too.

For the cargo-door example, the key locations for the fixture are the part clamping and pin locators. The reconditioning operations have to result in reduced weight of all functional areas and increased accuracy at all pinned areas.

Clevis-type hinged locators afford easy operation. Source: Paul W. Marino Gages Inc.

In the example of seven different cargo doors having several variations, a single modular fixture could allow all seven variations to be held through a series of pin location shifts having station numbers and color coding, clearly illustrated in the operation procedure. This allows operators ease of changeability. A series of organized labels and simplified operating procedures takes the guesswork out of the operators’ job.

On the plant floor, modular fixturing exists as a versatile and viable alternative to traditional welded tools. Operations that were once difficult for some employees because of weight and complexity now become simplified and ergonomically less imposing.