Common applications for wireless attribute torque wrenches and systems include the critical air, fuel and lubricant connections for gas and diesel engines. This integrated application requires each station provide positive electronic proof the line connection was properly torqued before the line will advance. Source: Sturtevant Richmont

Marketing and engineering have finally finished the design of the new product, and you must now evaluate the manufacturing process for your PFMEA. As you look at the process you encounter the same old problem you've faced before; critical fastener torques in locations where your transducerized power tools cannot reach. Worse, some of the air or hydraulic connections are safety items. How are you ever going to establish statistical control of these torques and how are you going to document it?

The traditional solution has been to use preset torque wrenches for their assembly speed and frequent auditing to verify the process. Did it work? Yes. But it required a significant amount of audit labor and time for after-the-fact data acquisition.

Relax, now there are numerous alternatives. In its place one can select the optimum solution from many digital torque wrenches and torque wrench systems that have come to market over the last five or six years.

"How do we get data for process control?" has become a series of questions, including:

- Do we want variable data, attribute data

or both?

- Do we want to tie the line controls to the assembly process or not?

- Do we need immediate data or batch data?

- Do we want ± 4% torque accuracy or ± 1% from the tools?

- How much less can we audit and how much money can we save?

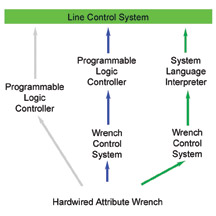

Varying line control systems both require and permit differing communication paths. These three paths are the most commonly used for attribute control with hardwired torque wrenches. Source: Sturtevant Richmont

History and choices

The first digital torque wrenches came out roughly a decade ago. They were great, except for their limitations. Data management was almost completely lacking. They were sensitive to many environmental conditions. They were somewhat fragile and they were expensive.About six years ago, the first nondigital communicating torque wrenches came to market. Using a different control path and communication system than digital torque wrenches, these tools were clicker-type torque wrenches that incorporated a switch activated by the clicking mechanism. The normally open switch closed when the tool entered the "clicked" condition and opened again when pressure on the tool was released for the mechanism to reset. The closed circuit had a duration of current flow that could be measured.

Comparing this to time standards, developed through experimentation, disclosed whether the tool had been jerked (too short a time), used correctly (correct time interval) or had been pulled past the click (too much time). Because this was occurring on a preset torque wrench, control of the tool was obtained by periodic calibration and interim checks. Control of the operator's use of the tool was obtained by measuring the time it was in the clicked position for each fastener. If the tool and how it is used can be controlled, one has basic control of the process.

Extending this was the ability to count the number of correct "clicks" or wrench cycles. If there were three fasteners to be tightened by the tool for the assembly, a correct assembly would have three wrench cycles, each with the proper duration.

This provided attribute data from the process; an OK was available from the device that measured the duration of the cycles. The cable from the wrench could be tied to either a proprietary system controller that measured the duration of each click and batched the information if desired. After that, a batch acceptance signal was sent to a PLC, or the tool could be wired directly to a PLC that would measure signal duration and count the number of correct signals from the tool. Regardless of the path chosen, the process could be tied to the line controls and a 100% OK/NOK attribute condition check applied.

In RF attribute systems, the need for an RF controller requires the use of proprietary control systems for the wrench communications. These systems also communicate with the line control system, whether it is proprietary language-based or PLC-based. Source: Sturtevant Richmont

These systems have been proven popular for their ability to provide attribute data for 100% of the fasteners on each assembly. In addition to providing attribute data for analysis, these systems can be used to apply controls to limited-access joints and pneumatic and hydraulic connections, and to simultaneously reduce joint audit frequency. Further, they provide the ability to immediately communicate to the line control system the status of the fastening process resulting in full integration.

Digital torque wrench development did not stand still during the past decade while the communicating attribute systems advanced. As electronics manufacturing made progress, so did digital tools and the understanding of how they could advance process control.

Today's digital torque wrenches offer almost the same options for process control as transducerized power tools, extending the ability to apply appropriate controls to the most remote fasteners. In two areas they perform functions that a power tool cannot: remote assembly where the tool goes to the product instead of the reverse and torque auditing. In both cases, the torque wrench portability permits the rapid and effective data acquisition needed to ensure quality.

Variable data (digital) torque wrench systems use computers and proprietary software to control specification downloads and torque data uploads. Most can provide both variable and attribute data to both the operator and the line controls. Source: Sturtevant Richmont

One can still obtain digital torque wrenches having a single set of stored specifications and a large memory capacity because the need for such a combination still exists. However, there are now wrenches that can hold up to 50 different torque specifications, such as might be needed if one is taking the wrench to a remotely located large product to attach several components, or running an audit route on an assembly line.

There also are versions of these tools that tie directly to the assembly line controllers, communicating actual torque values and attribute data within seconds of every use. This permits real-time control and offers the ability to feed the data to statistical analysis software, line controllers or both. Virtually all of these tools offer immediate operator feedback through an LCD and many offer other visual or tactile feedback mechanisms as well.

Advantages and selection considerations

The results of these technological advancements and proliferation of options are many.During process development, one can obtain data for ongoing control with the actual tools used on the fasteners for that specific assembly. This increases confidence in the process and permits more accurate prediction of the process output.

Appropriate process controls can be applied to all safety-related or mission-critical fastener torques, even when the installation is in a limited access area or on a pneumatic or hydraulic connection. The selection can be made to use variable data, attribute data or both for ongoing control, and whether real-time or batch data is preferable.

When selecting torque wrenches it always has been necessary to choose the unit of measure and tool capacity. The new systems, both digital and preset click-communicating, require that thought be given to some topics not previously associated with torque wrenches. Among these are:

- Will this tool and system be used for process development, production, or both?

- Will this tool be used on an assembly line or will it be used in remote assembly?

- Is communication with the line controls needed; what I/O capabilities are needed, if any?

- Should this tool and system to communicate through a computer port or through a PLC I/O system?

- What is the maximum number of different fastener torque parameter sets the system needs to handle at any given time?

- What, if any, proprietary and or legacy IT and control systems must this system communicate with?

- What types of process control should be applied, and how automated should the application be?