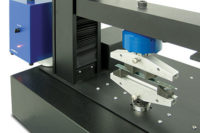

Standard ASTM E8 Tensile Specimen. Gage marks spaced at 2 inches are applied with a punch. Source: Admet Inc.

Ductility is defined as the ability of a material to deform plastically before fracturing. Its measurement is of interest to those conducting metal forming processes, to designers of machines and structures, and to those responsible for assessing the quality of a material as it is being produced.

A tensile specimen is pulled to fracture. The region where necking occurs is depicted. Source: Admet Inc.

Two measures of ductility are elongation and reduction of area. The conventional means by which these measures are obtained is by pulling a specimen in tension until fracture. ASTM E8 Standard Test Methods for Tension Testing of Metallic Materials governs the determination of elongation and reduction of area for metals.

Relationship between Slimness Ratio, K, and Elongation. As the slimness ratio decreases, the measured elongation increases. Source: Admet Inc.

Related Reading

Elongation is defined as the increase in the gage length of a test piece subjected to tensile forces divided by the original gage length. Elongation is expressed as a percentage of the original gage length and is given by:

Elongation (%) = 100 x ∆L/Lo Eq. 1

where Lo is the original gage length.

DL is the change in length of the original gage length when measured after the specimen fractures and the specimen is fitted together.

The original gage length, Lo, as specified in E8 is usually 1, 2, 4 or 8 inches and is dependent on the size of the specimen. A punch is often used to apply the gage marks to each specimen. The change in gage length, DL, is determined by carefully fitting the ends of the fractured specimen together and measuring the distance between the gage marks.

In reporting the elongation, ASTM E8 requires both the original gage length and percentage increase. If any portion of the fracture occurs on or outside a gage mark, the elongation and reduction of area may not be representative of the material.

Reduction of area also is expressed as a percentage and is given by:

Reduction of Area (%) =

100 x (Ao – Af)/Ao Eq. 2

where Ao is the original cross sectional area.

Af is the cross sectional area after fracture and corresponds to the narrowest part of the neck which occurs at the point of fracture.

Test Parameters Affecting Ductility

Elongation results are affected by changes in gage length, specimen geometry, and speed of testing or strain rate. In addition, heat dissipation caused by devices that contact the specimen, such as grips and extensometers, become a factor when specimens are not tested at ambient temperatures.

- Gage length. Gage length is important to elongation values, however, as the gage length increases, elongation values become less dependent on the gage length. When a specimen is pulled in tension to fracture, a region of local deformation occurs, called the neck.

Necking occurs as the force begins to drop after the maximum force has been reached on the stress strain curve. Up to the point at which the maximum force occurs, the strain is uniform along the gage length, meaning that the strain is independent of gage length. However, after necking starts, the gage length becomes important. When the gage length is short, the necking region occupies a much larger portion of the gage length. Conversely, for longer gage lengths, the necking occupies a smaller portion of the gage length. As a rule, the larger the gage length, the smaller the measured elongation for a given material. - Specimen dimensions. The cross sectional area of a specimen also has a significant effect on elongation measurements. The slimness ratio, K, is defined as the gage length divided by the square root of the cross sectional area.

K = Lo/ √Ao Eq.3

where Lo is the original gage length.

Ao is the original cross sectional area of specimen.

Experiments have shown that as the slimness ratio decreases, the measured elongation increases. Holding the slimness ratio, K, constant will minimize the effect of changes in specimen dimensions on elongation.

Reduction of area is normally measured only on round test specimens because the shape of the reduced section in the neck remains essentially circular throughout the test. With rectangular test pieces, the corners prevent uniform flow from occurring, and consequently the shape in the neck is no longer rectangular. In general, as reduction of area increases, the minimum allowable bend radius for a sheet material decreases. - Testing speed/strain rate. Generally, higher strain rates have an adverse effect on the ductility of materials, meaning that elongation values decrease as the strain rate increases. Metals that are brittle are more sensitive to strain rate. Also, the strain rate sensitivity of metals is quite low at room temperature but increases with increasing temperature.

Source: Admet Inc.

Elongation and Reduction of Area

The occurrence of necking in a tension test makes it impossible to convert an elongation measurement to a reduction of area measurement. While they usually vary in the same way as a function of test temperature or alloy content for example, it is not always the case.

Elongation and reduction of area measure different types of material behavior. Provided the gage length is not too short, elongation is chiefly influenced by uniform elongation and thus is dependent on the strain-hardening capacity of the material. Reduction of area is more a measure of the deformation required to produce fracture and its chief contribution results from the necking process.

Because of the complicated stress state in a neck, values of reduction of area are dependent on specimen geometry and deformation behavior, and they should not be taken as true material properties. However, reduction of area is the most structure-sensitive ductility parameter, and as such it is useful in detecting quality changes in a material.

Sidebar: Test Methods and Specifications

Material properties that have a direct or indirect influence on formability and product quality include:

- Ultimate Tensile Strength

- Yield Strength

- Young’s Modulus

- Ductility

- Strain Hardening Exponent

- Plastic Strain Ratio

All of these parameters can be determined by cutting a test specimen from the blank and performing a tensile test.

Included is a list of ASTM test specifications that governs the determination of these parameters:

- ASTM E8/E8M Standard Test Methods for Tension Testing of Metallic Materials governs the determination of Ultimate Tensile Strength, Yield Strength plus Elongation and Reduction of Area which are measures of ductility.

- ASTM E111 Standard Test Method for Young’s Modulus, Tangent Modulus and Chord Modulus is used for determining Young’s Modulus.

- ASTM E646 Standard Test Method for Tensile Strain-Hardening Exponents (n-values) of Metallic Sheet Materials is used for determining the Strain Hardening Exponent.

- ASTM E517 Standard Test Method for Plastic Strain Ratio r for Sheet Metal governs the determination of r. Of all the mechanical properties determined by a tensile test, ASTM E517 is the most difficult and requires close attention to detail.

Copies of the ASTM test methods mentioned in this article may be obtained from ASTM, the American Society for Testing and Materials. The test methods are available from the ASTM Web site, www.astm.org, or through customer service by phone at (610) 832-9585, fax (610) 832-9555, e-mail [email protected] or mail at 100 Barr Harbor Dr., West Conshohocken, PA 19428-2959.