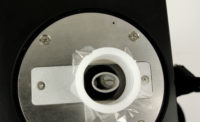

Sandvik had Innov-X install two Fox-IQ On-line XRF analyzers at its facility to provide automated material identification in the manufacture of stainless steel tubes and pipes. Source: Innov-X Systems Inc.

Sandviken, Sweden-based Sandvik Materials Technology produces high technology stainless steels, special alloy materials and advanced value-added products. The company wanted an efficient on-line system for testing seamless stainless steel tubes, and called on Innov-X Systems Inc. (Woburn, MA) to meet the challenge at its facility in Scranton, PA.

Sandvik has total control over the entire production process of the tubes, from steel melt to the finished product. The tubes are typically used within industries such as chemical and petrochemical, oil and gas, power generation, fertilizer, pulp and paper, and mechanical. They are made of stainless steels of special alloys based on nickel, titanium and zirconium.

Innov-X installed two Fox-IQ On-line XRF analyzers at the facility, totally automated elemental analysis systems that provide fast, positive material identification. Designed for high-throughput alloy sorting and quality control, the systems have made a significant impact on tube and pipe manufacture in Sandvik’s production line by providing quick, reliable, nondestructive alloy analysis.

The Fox-IQ On-line XRF analyzers automate online analysis for 100% high-volume process control. They deliver fast, accurate grade ID, pass/fail tests and chemistry with automated links to the quality control and quality assurance reporting system.

The Fox-IQ is controlled by an industry-hardened PC for start/stop, data acquisition, decision-making and communication to external devices. Engineered for nonstop operation in industrial environments, its compact design fits in virtually all existing operations. It offers a combination of flexibility, speed, accuracy and cost effectiveness, with worldwide service.

Russ Jones, general manager of Sandvik Materials Technology, says, “The installation of the inline Innov-X system has allowed us to reduce the test cycle time by more than 50% when compared to the previous system. The result is increased production throughput. In addition, the Fox-IQ has been very stable, and our inspectors find it easy to set up and operate.”

There are many different steel alloys used in Sandvik’s product lines. All must be matched with customer requirements before, during and after manufacturing. Keeping a constant eye on the alloy content in production is a major task for both production and quality control, and now that is done faster using the Fox-IQ system. Its FastID mode provides alloy grade and chemistry in as little as 5 seconds.

- Innov-X Systems Inc.

(781) 938-5005

www.innov-x-sys.com

Reply 53