Like visible light cameras, thermographic cameras and their associated software can recognize the size, shape and relative location of target objects. Source: Flir Inc.

Manufacturing engineers are constantly looking for solutions to improve production quality in their automated processes. By using infrared cameras in automated systems, there is the opportunity to improve process monitoring and control, quality assurance, asset management and machine condition monitoring. Jason Styron, business development manager, Flir Inc. (North Billerica, MA) addresses the key components of thermography.

Q:What is thermal imaging?

A:Thermal imaging sees heat within the infrared (IR) spectrum-radiation not detectable by the human eye, digital (visible light) video or still cameras. An IR camera can convert the radiation it detects into a visual image that depicts temperature variations across an object or scene. Some IR cameras are designed only for qualitative uses, providing relative temperature differences. These are used in IR cameras for law enforcement, maritime thermal night vision navigation, in automobiles and for monitoring applications where thermal images are interpreted based on temperature contrast.

But cameras designed for thermography application not only capture thermal images of objects, they also provide accurate noncontact temperature measurements of those targets. These quantitative measurements can be used in a variety of monitoring and control applications in industrial and manufacturing environments.

Essentially, if you need to see what a target or product looks like from a heat or temperature perspective, a thermography camera for automation is a valuable and efficient option. Compared to a spot radiometer, which is limited to a single spot reading and requires precise aiming at the point being measured, thermography cameras produce thousands of temperature measurement points.<

Like visible light cameras, thermographic cameras and their associated software can recognize the size, shape and relative location of target objects. Source: Flir Inc.

A:Thermal imaging has a wide and growing number of valuable applications: military, security, predictive maintenance, building diagnostics, law enforcement, search and rescue, medical, science, research and development (R&D), maritime navigation, automation and condition monitoring.

Consumer-based cameras also are being designed and manufactured for recreational boaters, outdoors enthusiasts and for automobile thermal night vision applications.

For automation, infrared machine vision is being used in a variety of manufacturing environments, including food production, iron and steel works, automobile component manufacturing and testing, critical vessel monitoring and predictive maintenance for mechanical equipment and electrical systems within those environments, among other uses.

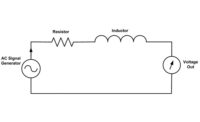

Q:How do thermal cameras work?

A:In many ways, thermal cameras operate similarly to digital video and still cameras. While the digital camera relies on a charged-couple device (CCD) detector to see light within the visible spectrum, an IR camera uses a resistive detector.

Each pixel on a thermal camera is a resistor, allowing the pixels to be sensitive to heat instead of light, which is how they pick up temperature differences and radiation within the infrared spectrum.

A variety of components and features determine the sophistication, image detail and level of functionality of thermal imaging cameras. The camera’s centerpiece is its infrared detector.

Resolution, thermal sensitivity, lenses and other features contribute to what makes a particular IR camera appropriate for a specific application and/or environment. Some are handheld models with viewfinders and liquid crystal display (LCD) screens, while others are fixed mounted (or mounted on pan/tilt devices) and operated by remote control.

Lenses determine the field of view and clarity relative to distance from the object. The resolution affects the number of pixels and spot measurements.

Finally, the detector sensitivity determines the range of temperature differences that the camera can capture to create the thermal image, the detail within that image and the data that complements it.

Shown here is production testing of car seat heater elements. Source: Flir Inc.

A:It may sound cliché, but it is true: thermal imaging provides a whole new set of eyes in industrial, manufacturing and automation applications-environments where the ability to see and measure temperature differences provides critical data that helps monitor and improve quality assurance, uniformity and safety, among other benefits.

Because of their combined imaging and temperature measurement capabilities, IR cameras can be cost-effective for noncontact observation. Like visible light cameras, thermographic cameras and their associated software can recognize the size, shape and relative location of target objects. The electronics in newer IR cameras provide fast signal processing that allows high video frame rates to capture relatively fast-moving parts on a production line. Their analog-to-digital (A/D) converters combine short integration times with 14- to 16-bit resolution, which is essential for properly characterizing moving targets or objects that change temperature rapidly.

Q:How are signal and image processing techniques used to solve machine vision applications involving thermography?

A:With GigEVision protocol, a near real-time IR vision system can be created in which almost all of the computer central processing unit (CPU) time can be dedicated to processing images. Making sure the IR camera also is GenICam compliant makes it easier for developers to integrate cameras in their IR vision systems.

Common tasks associated with IR cameras in machine vision systems include configuration settings, command and control, image processing and appending temperature measurement results to the image data stream. In addition, the camera’s digital I/O can be used to control other hardware, as well as triggering and synchronization functions that go with real-time data acquisition.

GigEVision makes hardware independence possible, while GenICam creates software independence. In a system with IR cameras compliant in both and connected to a GigE network, virtually any application program can command a camera to send a 60 hertz (Hz) stream of images without losing important data. The information can then be processed for alarm functions, trend analysis and statistical process control.

GigEVision and GenICam compliant cameras make it easier for third-party developers to integrate cameras into vision systems with a broad array of functions and includes the ability to define complex pass/fail decisions, control digital I/O, and communicate with serial or Ethernet devices, such as programmable logic controllers (PLCs), personal computers (PCs) and human machine interfaces (HMIs).

IR image of a circuit board indicates three spot temperature readings. Image colors correspond to the temperature scale on the right. Source: Flir Inc.

Q: How should customers go about choosing a thermal camera?

A: The most efficient path is for the customer to consult with their representative who can customize the best recommendation based on what the customer needs to accomplish, the environment/conditions that the camera would need to withstand and how the camera needs to interface to other software, hardware and systems.

In simple examples, if a customer needs to monitor a warehouse to prevent fires, machine vision would not be an appropriate solution where a smart camera would. If the customer needed to identify an anomaly in a manufacturing process, then machine vision IR cameras would be the best route.

Q: What types of applications are ideal for industrial thermography?

A: Applications ideal for industrial thermography include:

Noncontact diagnosis of mechanical equipment/motors

Electric utility equipment monitoring

Gas leak monitoring

Boiler and furnace inspection with through-flame cameras

Part production and assembly lines

Building inspection and energy auditing

Slag monitoring and ladle inspection

Casting, soldering and welding of metals and plastics

Product packaging

Nondestructive testing

R&D, prototyping and production in the electronics industry

Q: What are the advantages of using thermal imaging?

A: Some advantages of using thermal imaging include:

Nondestructive testing

Noncontact temperature measurement/analysis

Improved quality and uniformity

Reductions in wasted materials during manufacturing

Maximum uptime

Predictive and preventative maintenance

Improved safety in the work environment.

Jason Styron is business development manager at Flir Inc. (North Billerica, MA). For more information, call (866) 477-3687, e-mail [email protected] or visit www.flir.com/thermography.

A: The most efficient path is for the customer to consult with their representative who can customize the best recommendation based on what the customer needs to accomplish, the environment/conditions that the camera would need to withstand and how the camera needs to interface to other software, hardware and systems.

In simple examples, if a customer needs to monitor a warehouse to prevent fires, machine vision would not be an appropriate solution where a smart camera would. If the customer needed to identify an anomaly in a manufacturing process, then machine vision IR cameras would be the best route.

Q: What types of applications are ideal for industrial thermography?

A: Applications ideal for industrial thermography include:

Q: What are the advantages of using thermal imaging?

A: Some advantages of using thermal imaging include:

Jason Styron is business development manager at Flir Inc. (North Billerica, MA). For more information, call (866) 477-3687, e-mail [email protected] or visit www.flir.com/thermography.