BIC New Zealand Ltd. (Auckland, New Zealand), one of a number of BIC Corp. (Milford, CT) subsidiaries around the globe, manufactures about 15 million felt-tip pens each year using a customized automated assembly machine. These pens are then sold throughout New Zealand, Mexico, Chile, Canada and the United States.

Although reliable, the machine occasionally creates defective pens as a result of improperly fed parts or tips that split during insertion. In the past, the company relied on operators to spot defects. But, because of high-production speeds, guaranteeing consistent product quality was difficult, if not impossible.

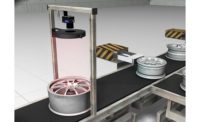

Faced with increased global competition and the high value of the New Zealand dollar, BIC realized it needed to solve this problem as part of an overall campaign to improve productivity and reduce its production costs. With this in mind, it installed a machine vision system that uses a pair of In-Sight 5100 vision sensors from Cognex Corp. (Natick, MA), one for tip inspection and one for end-plug inspection. The company also implemented special-purpose, LED-based lighting to increase imaging effectiveness and reliability.

“As a small plant we suffer from economies of scale compared to the larger plants offshore. We’ve looked at this technology before, but this time the price performance is at a level where we can justify the investment,” says plant manufacturing manager Bernie Jamieson. “I’ve been impressed with what this equipment can do, how easy it’s been to set up the inspections and how additional inspections can be added over time.”

The two vision sensors interface via digital I/O to an Omron PLC that controls the machine and rejects any failed parts. A touchscreen-panel PC running Microsoft Windows XP and Cognex In-Sight Explorer software acts as both the operator and programmer interface. Inspection data, along with associated failed images are logged on the PC. Inspection results can be viewed via a Web browser or loaded into Excel for offline analysis.

“Image logging is really useful,” says Jamieson, “Storing failed images allows us to see where the problems are. We can monitor trends and measure the effects of any design improvements we make to our products.”

Cognex Corp.

(508) 650-3000

www.cognex.com

Reply 15

Reprinted from ASSEMBLY Magazine

sidebar: benefits

- The two vision sensors interface via digital I/O to an Omron PLC that controls the machine and rejects any failed parts.

- Inspection results can be viewed via a Web browser or loaded into Excel for offline analysis.

- BIC can monitor trends and measure the effects of any design improvements they make to their products.