A screw-mounted lens tube and screw-on connectors for the USB port and the digital I/Os make the uEye RE dust and water proof. Source: IDS

It is no secret that the process conditions within industrial manufacturing environments are generally harsh. High temperatures, dust or lubricants make life hard for the sensitive electronics essential for automating the production processes. The modern cameras used in robot control or optical quality inspection are particularly affected. Their connectors and the fine mechanics of their lenses react very sensitively to external influences. Numerous OEM companies, such as the Germany-based companies Kaiser Computersysteme (Breitscheid) and Isotronic Bildverarbeitungssysteme GmbH (Bad Königshofen), therefore rely on cameras well suited for use in industrial manufacturing environments.

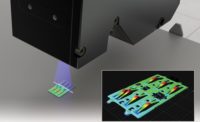

The two companies have been developing and manufacturing optoelectronic test and measurement systems since 1989. Under the product name IsotroniKa, they provide both standardized systems and customized machine vision solutions for many industries. The main application areas include surface inspection, completeness checks, optical measurements and automated test sequences.

The demands on quality assurance are particularly high in this case, as the strict Good Manufacturing Practice (GMP) Directive must be complied with. Among other requirements, the directive stipulates full documentation of the production process-which makes stability and reliability indispensable factors for the IsotroniKa systems.

The uEye RE USB cameras deliver strong performance even in harsh manufacturing environments. Source: IDS

Camera Solution

Smack in the middle of the manufacturing environment, the camera thus plays a key role. Since conditions at this exposed position are not always favorable, Kaiser and Isotronic rely on the uEye RE cameras from German machine vision specialist IDS (Obersulm, Germany) that are designed for heavy duty.These models are IP65/IP67 protection rated, which means that they are protected against ingress of dust or splash water. The protective function is ensured by a carefully sealed housing and a screw-mounted lens tube that encapsulates the sensitive lens.

The cameras are compact as well as rugged. Without the lens, the smallest version is approximately 41 by 41 by 41 millimeters in size and weighs less than 150 grams. To satisfy the vast variety of requirements, the uEye RE series features 19 different models with resolutions ranging from 640 by 480 to 2048 by 1536 pixels. The cameras are equipped either with charge-coupled device (CCD) sensors or with rolling or global shutter complementary metal-oxide semiconductor (CMOS) sensors in monochrome or color.

Supported by a comprehensive software package, the cameras integrate into OEM applications without major engineering work. The drivers and the software development kit (SDK) are included with every uEye camera.

Besides more than 20 different demo programs for camera integration and image acquisition, the SDK also comprises the corresponding source code in C, C++ and VB. Developers can quickly integrate these demos in their own applications and customize them as required. Kaiser, for example, uses the supplied driver as the basis for their own software wrappers to flexibly implement the camera models in self-developed programs.

The SDK supports all current Windows operating systems, including Vista, and additionally offers a TWAIN driver, an ActiveX component and a DirectShow/WDM driver for those using standard software solutions. All camera models from IDS use the same SDK-from the entry-level VGA model with USB port through to the high-resolution Gigabit Ethernet camera with a 5 megapixel sensor.

This software philosophy aids many OEMs who frequently use self-developed software for their systems. Changing from a USB camera to a powerful Gigabit Ethernet based camera is possible without problems. Instead of reprogramming the application, all one needs to do is adjust a few camera-specific parameters. This saves time and money. Kaiser plans to use the Gigabit Ethernet models from IDS beside the USB cameras to be able to cover greater distances between the place of inspection and the place of analysis. The changeover to the GigE models leaves them unperturbed, however, not only because of the “one-driver-fits-all” philosophy.

“We welcome working with a German manufacturer because we benefit not only from short distances regarding support and services,” says Manfred Kaiser, owner of Kaiser Computersysteme, “but also from a close personal contact.”

IDS Imaging Development Systems

(781) 787-0048

www.ids-imaging.com