Bombardier Aerospace (Montreal) designs, manufactures and supports aviation products for the business, commercial, specialized, and amphibious aircraft markets. To assist them with their symmetry and alignment check on the CRJ series of regional jets, they recently turned to InnovMetric Software’s PolyWorks/Inspector.

When an incident occurs with an airplane (such as being hit by a baggage transporter or a jet bridge, or after undergoing a hard landing) that requires the inspection of its structural engineering, Bombardier’s CRJ Ground Support Equipment team is rapidly dispatched to any location worldwide. “Knowing that a grounded airplane can sum up to $100,000 a day in lost revenue, we are committed to returning aircraft to service as fast as possible,” says Benoit Roby, CRJ ground service equipment coordinator at Bombardier.

Once the in service engineering team is on location, they determine whether the incident has caused any deviations or damage to the airplane that may impact its airworthiness limitation. This is done by inspecting the airplane, which includes the symmetry and alignment check.

The Challenge

Traditionally, the symmetry and alignment check takes two technicians and 12 to 14 hours to complete. To perform the check, target points are taken relying on the symmetry screws located on the airplane as datum points. The plumb bob line is then dropped to the floor and manually measured. Due to the extraordinary size of the airplane, obtaining the measurements is both time consuming and physically demanding on the technicians. Add to the equation the fact that reporting is manual, two technicians must be present: one to take the measures and one to record the results.

The kit used includes plumb bobs, precision optical levels, transit rulers, tape and numerous geometrical accessories. However, since the kit is aircraft-model specific, its accessibility is limited. And since it comes in an oversized crate, simply ensuring that the shipment follows along with the mobile team being dispatched to an international location is a feat. Additional costs, delays and customs issues are common. These complications have, on occasion, resulted in the team being forced to wait for the kit upon their arrival, making their time unaccountable during the wait.

Roby and his team reached the point where they needed to simplify their process with a portable system common to all airplanes. “Transport of the traditional symmetry and alignment kit had considerable drawbacks, which led us to consider a 3-D scanning solution; yet we were looking for a solution that would not affect the input or the output of our reporting system,” says Roby. “After selecting the portable 3-D hardware, I turned to our specialists in measurement systems of tooling services, and they highly recommended PolyWorks.” The goal of the CRJ Ground Service Equipment team was to eliminate equipment, save time, and make the measurement instruments as simple as possible, since not all technicians are 3-D metrology specialists.

The Solution

Roby’s team opted for the portable Leica Absolute Tracker AT401 and the 1.5-inch Corner Cube Reflector (CCR) combined with PolyWorks/Inspector software. The selected 3-D metrology solution is compatible with all aircraft—making limited accessibility a thing of the past. “The new solution is universal, portable and fits in our carry-on; this is a huge plus since we don’t even have to check in the equipment during air travel,” says Roby. Add a laptop and a homemade stand onto which the laser tracker is mounted, and the kit is complete—greatly simplifying transport logistics.

Yet the most noteworthy benefit is the major time savings: A symmetry and alignment check can now be completed with only one technician in six hours—and Roby even estimates that they will be able to do it in four hours.

“The ROI benefit of this solution is straightforward. What once took two men and up to 12 hours to perform can now be completed with one man in six hours, which amounts to huge savings,” says Roby. Also, since the previous method often encountered delays in transport, the CRJ Ground Service Equipment group was not able to set a flat service rate. With the 3-D metrology method, they can now estimate the costs, which is a significant plus because within an organization like Bombardier, being able to plan operations costs is key.

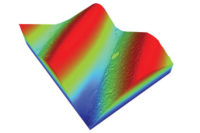

With PolyWorks, the entire symmetry and alignment procedure is robust and simplified. The technician arrives on location, sets up the equipment, and identifies the target points on the airplane. Once this is done, he begins measuring using the CCR, and PolyWorks does the rest. Operations such as determining the axis, moving the device, pairing, and adjusting to match are performed in PolyWorks. As each measure is taken, the data is instantly accessible in PolyWorks, and what’s more, it is automatically updated throughout the report.

PolyWorks pinpoints any human errors. “I have confidence in PolyWorks; if a mistake occurs in the process, it’s immediately identified,” says Roby. After the measurement of the target points is complete, the technician instantly gets real-time deviations with respect to the nominal points from the CATIA CAD model in PolyWorks, where Roby finds the interoperability of the software intuitive. In fact, the ease with which PolyWorks handles the model imported from the CAD software and the facility to generate reports were key factors that influenced Roby’s decision.

By using PolyWorks, it’s now easier than ever to generate reports. The results are exported to Excel and the standard report format in place remains untouched. “Due to the fact that we must adhere to the strictest international standards, we needed a solution that would not impact our model file. PolyWorks is easy to understand and use, plus it complies with our standards,” says Roby. PolyWorks also offers the reporting flexibility that the in service engineering team needs in the field since reports can now be done in real-time. Moreover, the InnovMetric technical support team closely collaborated with Roby to create reports adapted to his reality. The result: Reports are completely optimized, with no impact on the report model since the input and the output are exactly the same.

PolyWorks was initially purchased to assist the CRJ Ground Support Equipment team with their symmetry and alignment check, and it has proven that it can go beyond. By integrating PolyWorks into their inspection process, Bombardier reduced their symmetry and alignment check time by 75%.

InnovMetric Software Inc.

(418) 688-2061

www.innovmetric.com