Eddy current testing (ECT) is a nondestructive testing (NDT) technique used to detect surface and sub-surface defects using principles of electromagnetic induction. ECT offers tremendous flexibility in its ability to not only detect surface cracks, but also sub-surface indications. In the 1980s, ECT was considered the next big NDT technology and was touted as a replacement for magnetic particle inspection (MPI), but it never really took off as expected and the demand for ECT remained relatively stable. In the past two years though, ECT has witnessed large-scale adoption and demand across industries with many experts suggesting that the technique may finally reach its potential market. This article will provide a brief timeline of some of the major developments in ECT as an NDT technique, aim to decipher the reasons for its slow adoption and provide a picture of the future potential for ECT.

Decoding the Origins of ECT

ECT as a technique for testing finds its roots in electromagnetism, which was discovered accidentally by Hans Christian Oersted in 1820. While demonstrating that heat is developed if an electric current is passed through a wire, Oersted observed that the needle of a magnetic compass deflected perpendicular to the wire, while current was passing through it. In 1831, Michael Faraday, the father of electromagnetism, discovered electromagnetic induction—the operating principle of ECT. In 1834, Heinrich Lenz stated the principle that defines how properties of the test objects are communicated back to the test system. As such, the foundation for development of eddy current was laid by discoveries of Oersted, Faraday, and Lenz, but the actual discovery of the technology was by Léon Foucault in 1855. Finally, the first use of eddy current for NDT was in 1879 when D.E. Hughes used these principles to conduct metallurgical sorting tests.

Although there were a number of developments in the 19th century that were encouraging, much of the actual development of ECT as an NDT technique for industrial applications was carried out during World War II in Germany. Also, Dr. Friedrich Foerster, founder of Institut Dr. Foerster, made great strides in not only developing practical ECT instruments, but also marketing them. By the 1960s, Institut Dr. Foerster had developed ECT instruments covering almost all known applications of eddy current and worked with American manufacturers in making ECT popular in the United States as well. The major contributions of Dr. Foerster were the development of an impedance plane display that aided in communication of test information to the inspector and the formulation of the Law of Similarity that enables the inspector to duplicate the same eddy current performance under differing test conditions. The next major milestone in the development of the method was in 1974, when Intercontrole of France developed multi-frequency testing which was considered a very significant innovation, since it overcame the traditional limitation of sensitivity of single frequency eddy current technology to various conditions leading to challenging interpretation of the signal. The 1980s, considered the pinnacle for adoption of ECT, was marked by the introduction of microprocessor-based eddy current instruments in the market. Although portable microprocessor based ultrasonic test instruments have been available since the 1960s, the widespread incorporation of this technology to eddy current instruments took time. Nonetheless, this development enhanced the user-friendliness of the technique and created significant demand due to improvements in recording capability, sophisticated signal analysis and provision of automatic mixing of multi-frequency signals.

The Optimism of the 1980s Gave Way to Pessimism

At the absolute pinnacle of instrument development, as companies introduced newer feature-rich ECT instruments, eddy current was expected to finally provide a credible alternative to MPI as a technique to detect surface and sub-surface defects without taking off the paint or coating. However, the buzz around eddy current seemed to die as the industry found out that there was a major procedural limitation to the technique. An important aspect of inspecting critical infrastructure is the ability to confirm whether inspection has indeed taken place. Often, end user perception was that unless there were supervisors keeping a keen eye on whether the inspection was being carried out, the technicians or the inspectors would not cover the entire test area. This led to questions being raised about suitability of eddy current NDT, as the technique did not allow for verification of the inspected area. This limitation did not exist with MPI, since the paint or the coating had to be stripped off performing inspection using this technique. As such, there was a visible distinction between the areas that were inspected and those that needed inspection. As a result, there were apprehensions about adopting ECT and many technicians or inspectors that had qualified for ECT did not renew their qualification, as there was limited demand in the industry for ECT.

The Light after the Storm: Pessimism Leads to Innovation and Advancement of Technology

Coincidently, during the 1980s, after the buzz surrounding eddy current subsided, research continued on a number of advanced techniques with ECT as the base. These were remote field testing (RFT) and alternating current field measurement (ACFM). In the 1990s, eddy current array (ECA) came to the forefront and together with RFT, ECA and ACFM, changed the current landscape for eddy current technology. In 1984, Technical Software Consultants Ltd (TSC Inspection Systems) was established by a team of University College London’s professors to develop and market advanced ECT techniques. ACFM, an adaptation of ACPD, is a patented TSC Inspection Systems technology and, according to the company, the company is currently the sole provider of this technology globally. Parallel to ACFM development in the UK, in 1984, Dave Russell formed a research and development group to explore the suitability of RFT for inspecting ferromagnetic tubes. This group was successful in achieving its aim and spun-off commercially into Russell NDE systems. According to the company, it sold the first commercial product for RFT in 1988 and continues to evolve this product line by modernizing the design and adding features that not only increase user-friendliness, but also expand the technology’s application scope. RFT currently is among the preferred tools for heat exchanger tube inspection.

Flexibility of ACFM makes it a Game Changer for the Eddy Current Testing Market

Although industry experts often debate whether ACFM is an eddy current technology, ACFM has clear advantages over conventional eddy current such as better scan pattern, better response to variations in thickness due to coatings and most importantly ACFM is able to differentiate and characterize surface breaking defect up to a depth of 25 mm. ACFM has been extensively used in petrochemical complexes, refineries, rail bogeys, axles and rail track inspection; however much of its current market is being driven by demand from the offshore oil and gas industry. The flexibility of deployment that ACFM offers has made the technology widely adopted for applications such as weld inspection on nodal connections of jackets and subsea structures, circumferential welds on caissons, pipelines and padeyes, among other things. ACFM can be deployed using a diver, micro- or mini-remotely operate vehicles (ROVs) and also integrated with such complementary technologies like ultrasonic.

Eddy Current Array Greatly Enhances Speed of Inspection

In the 1990s, development on ECA technology started with the aim to greatly enhance speed on inspection and provide better probability of detection through an image, rather than a signal generated by conventional ECT instruments. According to the company, although ECA was first marketed by R/D Tech (now part of Olympus NDT), the real adoption is driven by Eddyfi who, consisting of eddy current technology experts, have not only considerably enhanced the application base of ECA technology, but also successfully established ECA as a mainstream NDT technique. ECA technology offers a number of advantages over conventional eddy current technology, such as sensitivity, coverage of inspection, speed of inspection and, most importantly, ECA provides a 3-D image that enhances interpretation and analysis capabilities. Moreover, similar to ACFM, a new configuration of ECA probe is being developed to allow detection and sizing of surface-breaking cracks. Since there is a multiple coil probe rather than a pencil probe, the sensitivity of inspection is less dependent on the operator’s skill level. This overcomes the biggest challenge in the NDT industry, which is the lack of skilled technicians. To put the success of Eddyfi and ECA technology into perspective, from being a relatively unknown company Eddyfi has now captured 80 to 90% of market share in the power generation industry for ECA inspection.

Advancement of Eddy Current Technology Aiding Adoption

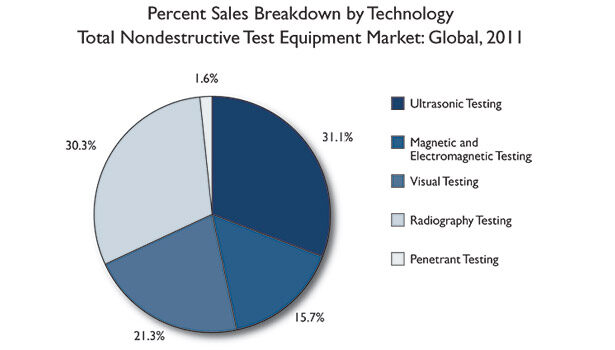

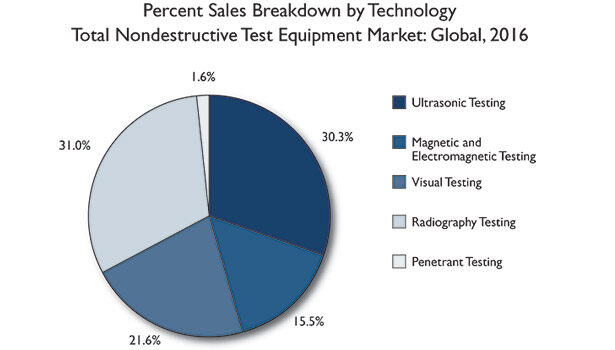

The 1980s is still considered the decade that redefined the landscape of eddy current testing. The initial optimism for a solution to replace techniques such as MPI gave way to pessimism due to the underlying inability to verify whether inspection had been performed. This in turn led to development of advanced techniques, such as RFT, ACFM and ECA, that enabled either recording of the inspected data points or provided a 3-D image of the inspected area that could be verified later. Although these advanced techniques have been around in the market since the 1990s and early 2000s, wide-scale adoption has only started during the past two years. The reach of these advanced techniques may be currently limited, but they have the potential to not only replace traditional surface inspection techniques such as MPI and penetrant testing, but also complement primary inspection techniques, such as ultrasonic testing is tremendous. Frost & Sullivan analysis in the global NDT equipment market in 2012 estimated the magnetic and electromagnetic NDT equipment market at $220 million, which includes conventional eddy current, MPI, ECA, ACFM and RFT. This market is projected to grow at 7.5% compounded annual growth rate to approximately $315 million by 2016. The current decade would hence seem to be another milestone in ECT with the technology expected to realize its much heralded potential.