A previous blog,Strategic planning: Issues and Resolution , described issues with the traditional strategic planning process and provided an alternative approach using the roadmap in Figure 1, where strategy creation is step number five, not one.

With this IEE system, strategies are created where there is an alignment to the financials and their improvement (i.e., step 4) with a strategic-statement wording that leads to projects that benefit the enterprise as a whole.

Figure 1: Integrated Enterprise Excellence (IEE) Business Management System1

With typical process improvement programs, such as Lean Six Sigma and Total Quality Management (TQM), there often becomes a hunt for process improvement projects that are to be conducted. Often with these traditional process improvement efforts the following occur:

These issues are overcome with the IEE system, where high potential areas are identified in step 6, so that owners of the 30,000-foot-level metrics that need improvement are asking/demanding timely completion of projects in their area, which are to enhance their reported scorecard’s performance. (See blog Applying 30,000-foot-level predictive metrics to business scorecards .

To be effective, these metrics need an automated system for updating the predictive-scorecard charts so that everyone can readily see how their (and other) performance metrics are performing on an on-going basis relative to the needs of the business. One approach to accomplish this automatic predictive scorecard updating is through the Enterprise Performance Reporting System (EPRS). Improvements to a process is demonstrated when its 30,000-foot-level statistical-time-series tracking chart transitions to a new, enhanced level of performance.

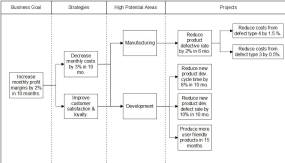

As part of the IEE system, an enterprise improvement plan (EIP) is an effective means to identify process improvement projects that positively impact the financials, as illustrated in Figure 2. The column titles in this figure align with steps 4-7 of the 9-step roadmap.

Figure 2: Example Enterprise Improvement Plan (EIP)1

Everyone knows that organizations need to improve in order to survive; however, what is often not considered is where process improvement efforts should focus so that the enterprise as a whole achieves its maximum benefit from these efforts and projects are completed in a timely fashion. The IEE system addresses these needs.

References:

Recent Comments

Therefore great deal to take place over kinds...

Gee… I translate writes on a similar to...

As it turned out, it is quite possible...

For some it is significant, and so research...

nike tiffany and co jacket