Home » computed tomography

Articles Tagged with ''computed tomography''

NDT in Aerospace

It is an exciting time to be in additive manufacturing.

Read More

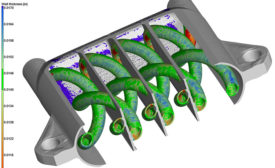

How CT Scanning Is Enhancing the Quality and Manufacturability of Medical Devices

This inspection technique is highly valuable for industrial metrology.

November 8, 2018

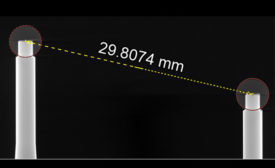

Computed Tomography: Optimizing Large Quantity Automated Measurements

Learn more about automated measurement techniques for large quantity screening applications.

October 8, 2018

Dispelling the Myths of CT

Advanced robotics, faster computers, and lean manufacturing processes are all combining to improve the efficiency of manufacturing.

October 1, 2018

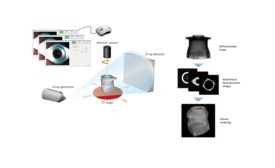

CT Inspection: An Inside Look at CT-Based Nondestructive Testing

CT scanning has become an important tool for many research, industrial, and safety critical applications.

August 7, 2018

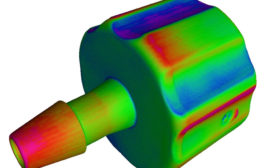

Industrial CT for Use in Additive Manufacturing Inspection

New part designs that would be impossible with traditional machining methods require new measurement tools.

August 1, 2018

INDUSTRY HEADLINE

Exact Metrology Hosts Dual Open Houses Demonstrating Newest Products And Equipment In Metrology

July 16, 2018

Looking Internally with Computed Tomography

Users from electronics manufactures to paleontologists see benefit of nondestructive inspections.

June 29, 2018

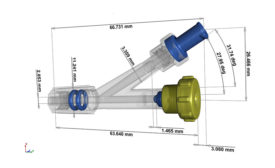

Medical Device Inspection with Industrial CT and X-ray

Managers can now capitalize on the data and be more responsive to production issues as they arise.

June 1, 2018

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing