Home » Frost & Sullivan

Articles Tagged with ''Frost & Sullivan''

Are CMM vendors ready for changing dynamics of end users?

Read More

INDUSTRY HEADLINE

2015 Manufacturing Leadership Awards Open for Nominations

August 22, 2014

INDUSTRY HEADLINE

Automation in Auto Industry Calls for Metrology Solutions

August 11, 2014

The Rebirth of Eddy Current Nondestructive Testing

Advanced techniques such as ACFM and Eddy Current Array are making rapid strides.

August 11, 2014

Market Analysis

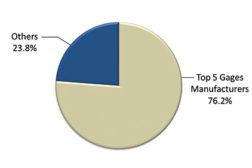

Cost-Effective Gages: Continue to Woo End Users

Research indicates average growth for the global gages market.

July 8, 2013

Market Analysis

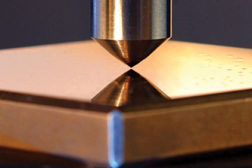

Hardness Testing: Market Analysis 2013

Market upbeat despite facing headwinds.

June 10, 2013

Analysis

Where is the Next Big Opportunity for CMMs?

The answer lies on the shop floor.

April 17, 2013

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing