To ensure product quality, manufacturers must consistently produce parts that meet or exceed specifications. Capability analysis, a powerful statistical tool that serves as a compass for quality departments, helps them do just that.

What is Capability Analysis?

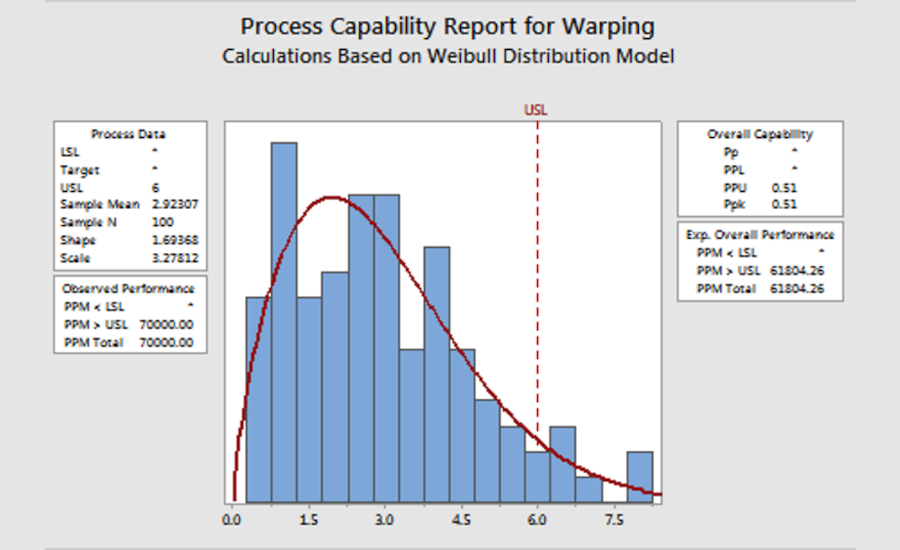

Capability analysis is a set of calculations used to assess whether a system is statistically able to meet a set of specifications or requirements. It quantifies the ability of a process to produce outputs that are within predefined limits. Think of it as a measure of how well a process can operate under optimal (or 'in-control') conditions.

Two main metrics derived from capability analysis are:

- Cp: This metric measures the potential capability of a process, assuming it's centered perfectly between the specification limits. It indicates the spread of the process variation relative to the spread of the specification limits.

- Cpk: This metric evaluates the actual capability while considering any shift from the center. Cpk measures the distance between the process mean and the closest specification limit, highlighting any skewness in process outcomes.

Capability analysis can benefit quality departments in the following ways:

- Identifying Variabilities: Every process has inherent variability, but capability analyses quantify those variances. By understanding the degree of variability, quality departments can strategize more effectively to reduce it, ensuring that more products are within specifications.

- Cost Savings: Products that don't meet specifications are either scrapped or reworked, both of which incur costs. By using capability analysis to hone processes, manufacturers can reduce these occurrences, leading to substantial cost savings.

- Customer Satisfaction: When processes are capable, it means they're producing products that meet specifications consistently. This leads to fewer defects, returns, and complaints, which in turn boosts customer satisfaction and brand reputation.

- Data-Driven Decision Making: are revered over gut feelings. Capability analysis helps manufacturers make decisions backed by hard data.

- Resource Optimization: By pinpointing processes that are less capable, resources—like time, manpower, and machinery—can be channeled more effectively towards areas that need improvement.

- Setting Realistic Specifications: Sometimes, the issue might not be with the process but with the specifications themselves. If a process consistently fails to meet too tight specifications, it might be worth revisiting those standards. Capability analysis can help organizations set more realistic and achievable specifications based on actual process capabilities.

- Risk Management: High capability indicates a lower risk of producing out-of-specification products. Understanding this risk is crucial for quality departments, especially in industries where non-conformance can have severe consequences, such as pharmaceuticals or automotive.

Capability analysis provides a clear picture of how well a process can produce products within specifications. It empowers quality departments with the insights needed to elevate process excellence, drive customer satisfaction, and achieve cost efficiencies.