Home » Keywords: » analysis

Items Tagged with 'analysis'

ARTICLES

Software & Analysis

Despite your best intentions, you cannot improve a process without first differentiating between common and special causes.

Read More

Software & Analysis

Measurement Systems Analysis

There are many ways to assess the quality of a measurement system.

September 27, 2023

Why Your Team Needs Statistical e-Learning Options

Six Sigma relies on statistics at its core. But using Six Sigma throughout an organization is not always straightforward.

December 9, 2022

Best Practices When Implementing SPC Charts

Control charts should be implemented carefully. Here are best practices to keep in mind.

July 13, 2022

Column | Darryl Seland

Oh, Behave! Navigating Behavioural and Organizational Change

December 20, 2021

The Evolution of Calibration Documentation

Calibration software is the most advanced solution available to support and guide calibration management activities.

December 2, 2020

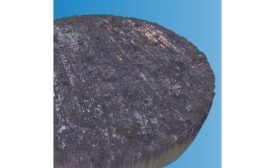

Fully Characterizing Brake Pad Materials to Improve Performance and Lower Development Costs

Combining benchtop mechanical testing of smaller brake material samples with rapid 3D surface metrology makes it possible to analyze results more quickly than ever before.

September 1, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing