There are many root causes of defects, mistakes, errors, and variation. One sometimes overlooked is measurement. A poor measurement system can let defective products slip through and send good products or scrap. That’s why companies need measurement systems analysis (MSA).

MSA will help evaluate your measurement methods and tools to determine if they are reliable and repeatable. Poor measurements can harm your productivity and profits. There are also ways to fail at MSA. Let’s look at ways to succeed and fail at MSA.

Gage Repeatability And Reproducibility (GR&R)

There are many ways to assess the quality of a measurement system. Gage Repeatability and Reproducibility (GR&R) uses a single gage, 10 or more parts, one to three appraisers and one or more trials per appraiser. Types 1-2 and Attribute are the most common types of GR&R.

Type 1 GR&R

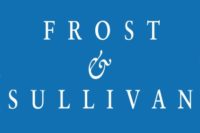

Type 1 GR&R uses one appraiser, one gage and 50 parts. It’s a good first step to assess your measurement system. Each part must have a known reference value (measured independently to a high degree of accuracy) and upper/lower specification limits or tolerance. Because the calculations are non-trivial, consider getting software to help with the analysis. Figure 1 shows a Type 1 GR&R where Cg and Cgk (capability) are greater than 1.33. The measurement system is acceptable.

Type 2 GR&R

To conduct a Type 2 GR&R you will need a single gage, two or more appraisers and 5-10 parts. Label each part so that you know which one is being measured. Have each appraiser measure each part at least twice. Have them do it randomly so that they can’t remember what the previous value was. Then input the data into MSA software to analyze GR&R.

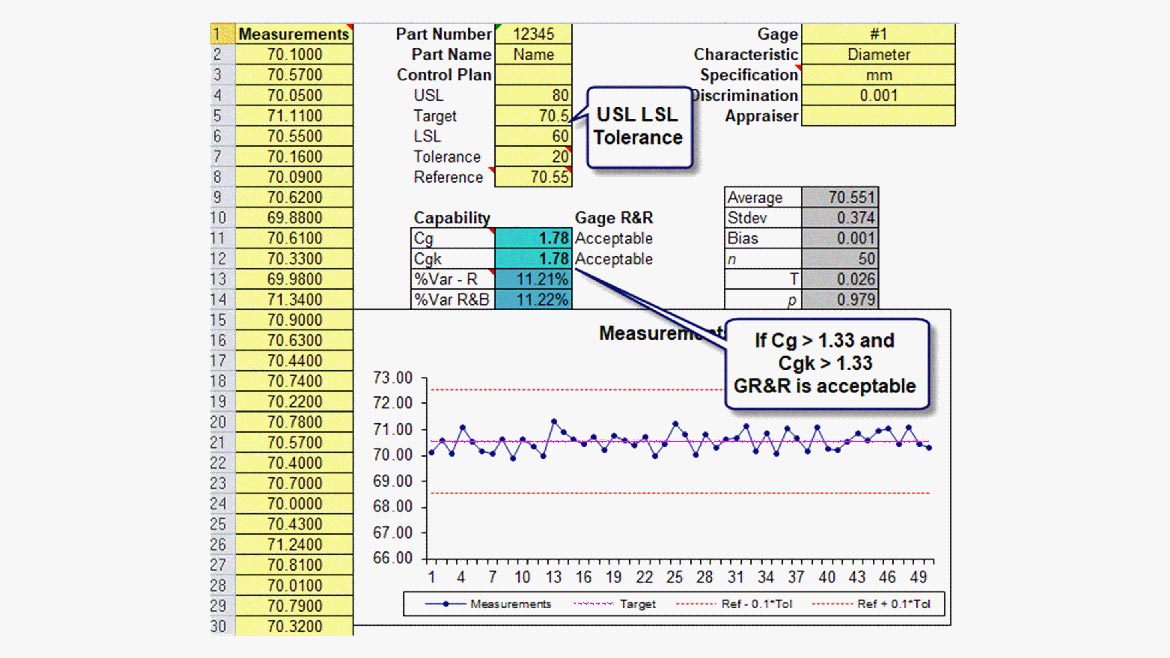

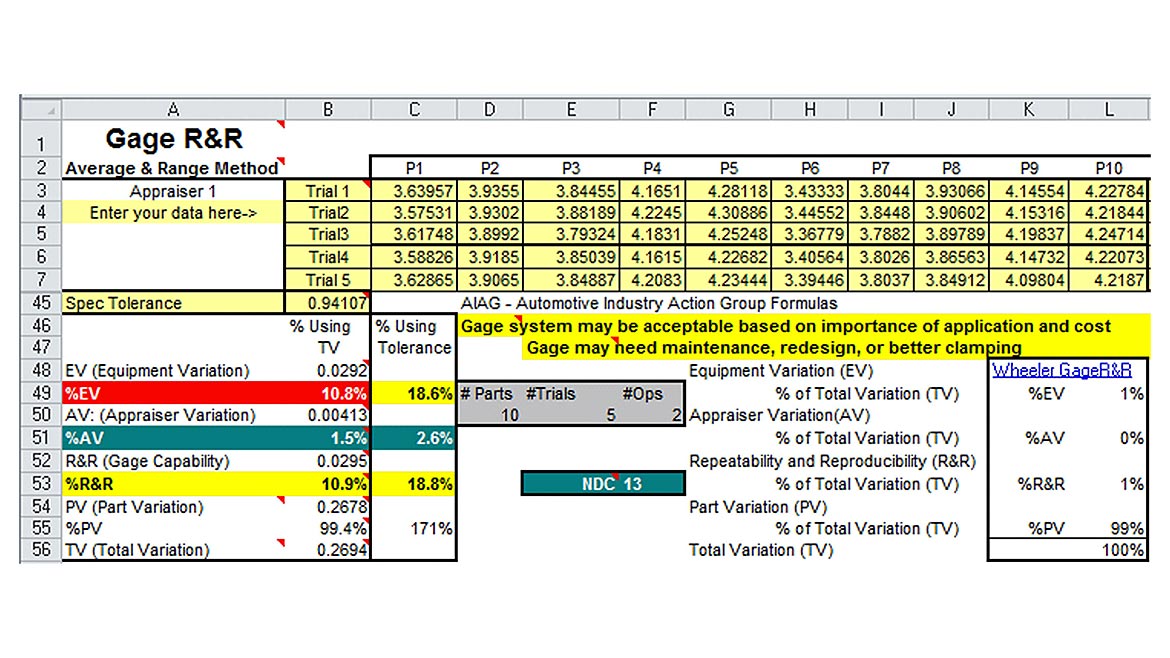

Ford® published verification data (Figure 2) that can be used to validate any MSA software.

There are at four main ways to analyze this data:

- Average and Range Method

- ANOVA Method

- Specification Tolerance Method (if you cannot measure enough part variation)

- Dr. Donald Wheeler’s Honest Gage R&R Method

The biggest mistake beginners make is using 10 parts from the middle of a production run. There won’t be enough part variation to get a good GR&R. You need bad parts to do a good GR&R or at least 5-10 parts that span the specification tolerance. You might want to pull parts from startup, middle and shutdown of a production. Or get parts from rework or scrap.

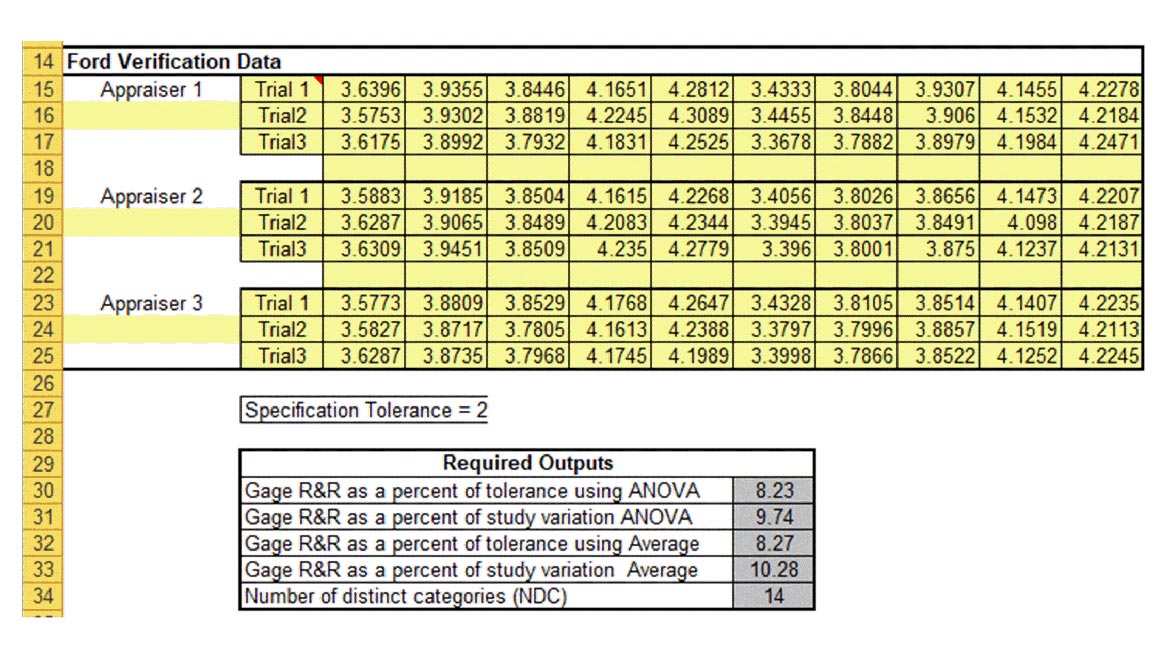

How will you know if you have enough part variation? There’s a calculation called NDC (Number of Distinct Categories) that must be greater than or equal to 5. Ford’s data has an NDC of 14. This example (Figure 3) shows all four methods:

Interpreting Results

If NDC >=5, then the analysis is straightforward. You will want most of the variation to be between the parts, and less than 10% to be caused by the measurement system (appraisers and equipment). In this case, the ANOVA method is less than 10% while the Average and Range method is just over 10%. If NDC < 5, there is not enough part variation to use either ANOVA or Average and Range Method.

Gage R&R System Acceptability

- %R&R<10% - gage system okay

(Most variation caused by parts, not people or equipment)10%> - % R&R<30% - may be acceptable based on importance of application and cost gage or repair< li>

- % R&R>30% - Gage system needs improvement

(People and equipment cause over one-third of the variation)

30%>

How To Improve

- If %EV (equipment variation) is greater than %AV (appraiser variation), then the gage may need maintenance, redesign, or better clamping.

- Gage needs maintenance (gages can get corroded or worn)

- Gage needs to be redesigned to be used more accurately.

- Clamping of the part or gage, or where it’s measured needs to be improved (imagine measuring a baseball bat at various places along the tapered contour; you’ll get different results).

- Excessive within-part variation (Imagine a steel rod that’s bigger at one end than the other. If you measure different ends each time, you’ll get widely varying results).

- If %AV is greater than %EV, the appraisers may need better training because they are not getting similar results.

- Operators need to be better trained in a consistent method for using and reading the gage.

- Calibrations on the gage are unclear.

- Fixture required to help the operator use the gage more consistently.

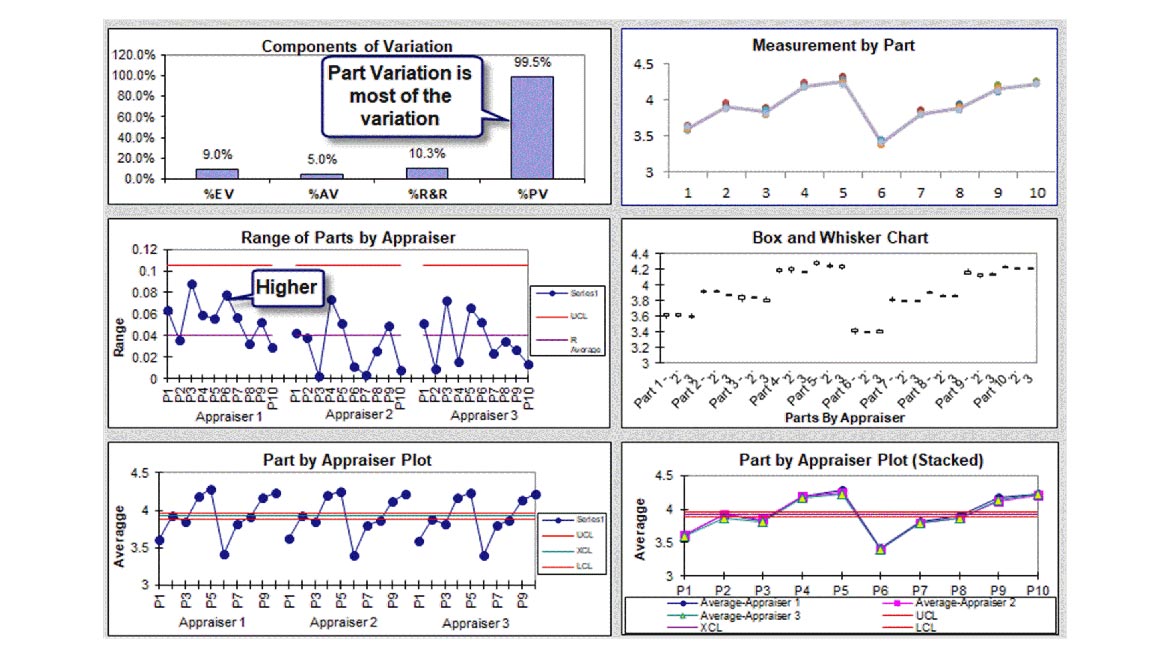

You can analyze the performance of each appraiser using graphs (Figure 4) provided by MSA software. Appraiser 1 range (variation) is slightly higher than appraisers 2 and 3.

Common Mistakes People Make

Many people don’t like the answer they get using Gage R&R. Most of the time, it’s because they didn’t follow the instructions for conducting the study. Here are some of the common mistakes I’ve seen:

- Forgetting that the Gage R&R study is evaluating their measurement system and NOT their products. Gage R&R does not care about how good your products are. It only cares about how well you can measure your products.

- Using only one part. If you only use one part, THERE CAN’T BE ANY PART VARIATION, so people and equipment are the ONLY source of variation.

- Using too many trials (if you use five trials, you have more opportunity for equipment variation).

- Using too many appraisers (if you use all three, you have more opportunity for appraiser variation).

Using a gage that measures in too much detail. If your part is 74mm +/- 0.05, then you don’t need a gage that measures to ten thousandths of an inch (0.0001) you only need one that measures to the hundredth of an inch (0.01).

Type 3 Gage R&R

Typical Gage R&R studies use 10 parts, 2-3 appraisers and 2-3 trials (3 x 3 x 10). What do you do if you use a coordinate measuring machine (CMM), not humans? A Type 3 GR&R study (Figure 5) uses 30 parts, one appraiser (CMM), 5 trials (1 x 5 x 30). This works like the Type 2 GR&R, except that there is only one appraiser. You might consider randomizing the parts for each successive run.

Attribute Gage R&R

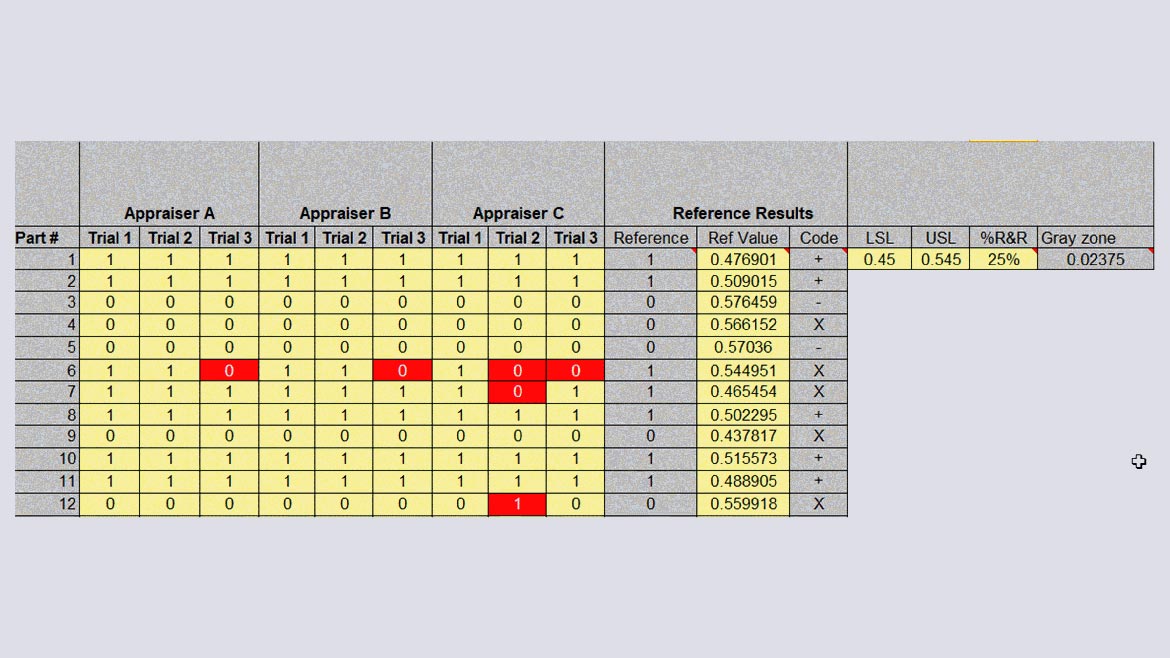

When using pass/fail gages or measurements, use attribute GR&R to access the measurement system. You will need 50 parts, 2-3 appraisers conducting 2-3 trials. You will also need reference measurements for each part measured to know if it passes or fails. Here’s an example from the AIAG (Figure 6). Each appraiser registers a pass (1) or fail (0) for each part three random times. This is compared to the reference value and spec limits. Red cells show errors. Appraiser C seems to have more misses.

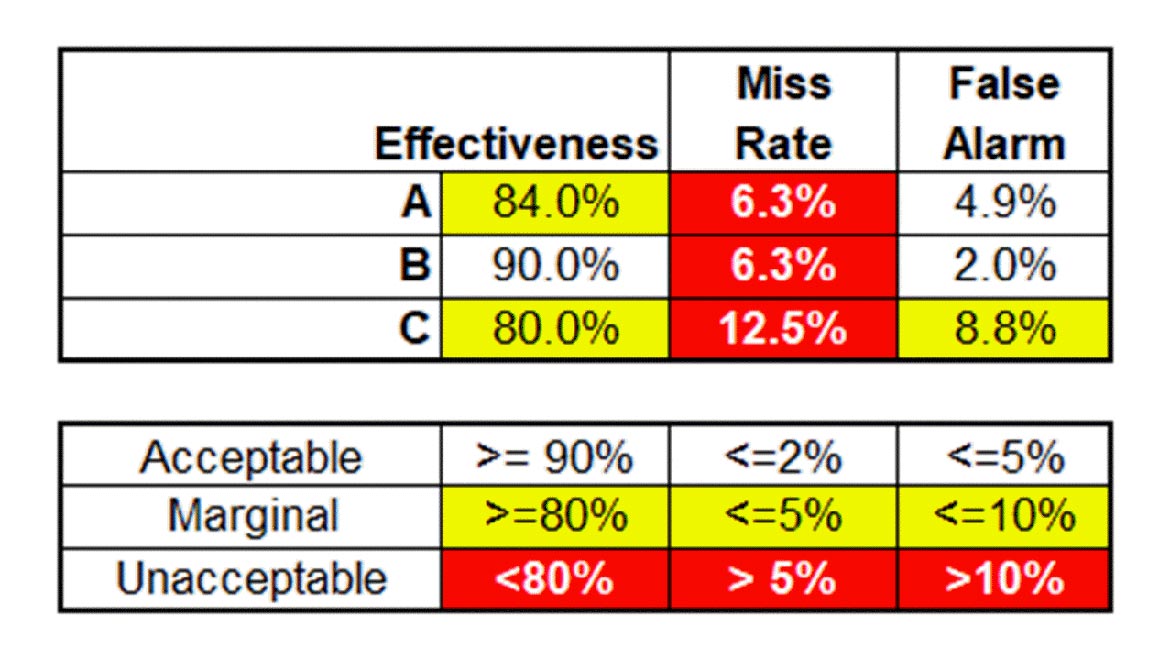

This is then used to assess the gage system. In this case the miss rate is too high (Figure 7). Appraiser C’s miss rate is almost twice as high as appraiser A and B, and the false alarm rate is too high. So, this measurement system needs improvement. Pass/fail gages can wear over time and cause problems with accuracy.

Conclusion

Measurement systems can reject good parts and accept bad ones. Measurement Systems Analysis can help determine how to improve the measurement system to prevent waste and rework.

If you aren’t already using MSA, your customer may demand it at some point. It’s better to get ahead of their request rather than scrambling to figure out MSA.