Visualize the large tool, the cabinet of Figure 1, being on your company’s or agency’s premises. What is it? What can you use it for? It’s mainly intended for stressing, for finding weaknesses in, your electronic and other assemblies.

Hot-cold stressing

The air volume above the “specimen” plate is sometimes electrically heated by flowing through current-carrying electrical resistors in the topmost compartment. At other times the air volume above the “specimen” plate is cooled by liquid nitrogen or by refrigeration. Air, alternately hot then cold, is directed at or through your electronic and other assemblies. Why? To thermally stress them, to alternately expand and contract their materials at various rates.

Hammer-excited stressing

In this article let’s focus our attention on the large “specimen” plate itself. Note the many threaded inserts for attaching your test articles. The plate is flexibly attached to the cabinet, so that the plate can move, can vibrate in multiple axes. The plate is driven from beneath by a large number of compressed air-driven variable-rate RS or repetitive shock elements, air hammers, resembling Figure 2. (slide 25.88). They are fed by the compressed air hoses visible under the plate, Figure 1. The RS units are attached at various locations and on various compass headings, angled upward into the flexibly-attached plate, causing the plate to move in multiple axes.

Does that large 48 inch square plate move as a solid body? No. It resonates and flexes at its several natural frequencies.

You probably intend to attach electronic and other assemblies to the softly-sprung plate. Attaching will be eased by the front - now open and rear - now closed doors. All doors will be closed during operation to permit thermal cycling and to keep most of the noise inside.

Measure

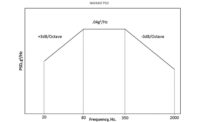

You probably want to know the severity of the multiaxis vibration at each of the locations where you attach test articles. Plan to attach a tri-ax accelerometer at each location. Measured values will differ markedly from each other and from what’s being sensed by that lonely accelerometer whose white cable is visible in Figure 1. Is the lonely accelerometer representative of the others? I’d say no. Could any of those spectra be made to resemble the lower graph of Figure 3 (slide 25.75), which comes from the Navy’s document Navmat P9492? Again, I’d say no. I think with wide variations an d rapid changes they’ll somewhat resemble the upper graph.

ESS, HALT, HASS?

Compared to the single-axis-at-a-time ESS or environmental stress screening vibration sought by P9492 in 1979, multiaxis Figure 1 has come a long way in speed and effectiveness. Temperature and dynamic stressing are now applied simultaneously, rather than alternately, saving much time and dangerous handling of products..

When these stimuli are applied as part of new product development, they are often called HALT or highly accelerated life testing. That’s misleading. These efforts are not a prescribed test that a product passes. Rather, severity is increased until assemblies fail in some way. Root cause of the failure is sought and remedied.

When these stimuli, slightly lessened, are applied to post-production lots, they are often called HASS or highly accelerated stress screening. Here we don’t want failures.

Is this random vibration?

In my short courses I deal first with one-frequency-at-a-time sine vibration. Then with several-discrete-frequencies-simultaneously complex vibration. Then with continuous spectra, with all-frequencies-simultaneously random vibration. And finally with shock, including RS or repetitive shock. Does the unit of Figure 1 and similar units from other vendors deliver random vibration? Not exactly. Repetitive shock lacks stationarity; its spectrum changes violently from moment to moment. Does that matter? Authorities differ.