In a society that is inundated with cell phones, PDAs, laptops and Internet cafes, it is little wonder that digital handheld tools have followed suit in the wireless trend. No longer tethered to a computer, users of digital handheld tools have increased mobility to get those hard-to-reach measurements.

A gage interface, which links the handheld tool to a computer, is actually two devices: a protocol converter that converts the proprietary output from a variety of gages to a standardized output, such as RS232, that is connected via cabling to a PC. But running a cable directly to the PC can be unwieldy, if not impossible, such as when operators take measurements behind a giant engine block or under a vehicle.

In those cases, a wireless RS232 system may be the solution. Tom Lutz, president of TAL Technologies Inc. (Philadelphia), says several technologies are available for wireless RS232 communications: wireless RS232 transceivers, serial infrared, wireless Ethernet and Bluetooth serial.

Wireless solutions

Lutz says one of the more common options is wireless RS232 transceivers, which he likens to a walkie-talkie. "Instead of having a cable with an RS232 connector on either end, there is a wireless transmitter with an RS232 connector on one side and an antenna on the other, and you plug one on each end of the connection and the two transceivers communicate with each other just as if there were a wire. It's just a matter of unplugging the wire and replacing it with a transmitter/receiver pair."

Serial infrared uses an infrared transceiver to encode and transmit RS232 data signals over a beam of infrared light, similar to the way a TV remote control works, to another transceiver that decodes the signal, says Lutz. Each device is plugged into a transceiver and the two transceivers need to be in each other's line of sight. "If you break the beam because you're underneath a vehicle or behind a big engine block, then you don't have a straight line of sight to the receiver and the data doesn't get through," explains Lutz. "The whole reason for going wireless in the first place with a tool is so that you can be free to move around and go wherever you want."

Serial device servers are boxes that have an RS232 port on one side and an Ethernet connection on the other. "These wireless serial servers provide a wireless connection to a device that has a serial output, whether it's a measuring tool or a balance or bar code scanner. You can move that instrument wherever you want in the network, wirelessly," says Lutz.

An example of a serial device server is a print server for all of the printers in an office. A printer is plugged into the network and everyone in the network can use the printer without a direct wire connection because all of the data is going through the network. "As far as your computer knows, the printer is plugged in just as if it's directly plugged into the back of your computer," says Lutz.

The Bluetooth wireless technology is an open specification for a personal area network connection among mobile computers, mobile phones and other devices. The Bluetooth wireless technology specification provides secure, radio-based transmission of data and voice. It delivers opportunities for automatic wireless connections, even when devices are not within the line of sight. The Bluetooth wireless technology uses a globally available frequency range to ensure interoperability no matter where one travels.

"Because it's being built into many new laptop and desktop computers, it's a big standard for interconnectivity to a PC," says Lutz.

He explains that any time a device that has a Bluetooth wireless connection nears another device with a Bluetooth wireless connection, "the software that each device has starts to recognize that the other device is there and they each start to automatically install drivers so that the computer can communicate with that device. From that point on, it's as if that device is plugged in. Instead of physically plugging that device into the computer, you just move the device somewhere near the computer. The idea is that you don't need a cradle anymore. You just walk into a room that supports Bluetooth and you can automatically connect to your PDA, or another supported device, and talk to it without having to plug in anything."

Lutz says this is particularly exciting for measuring instruments and laboratory instruments because Bluetooth provides a low-cost option for wireless communication.

Two-way transmission

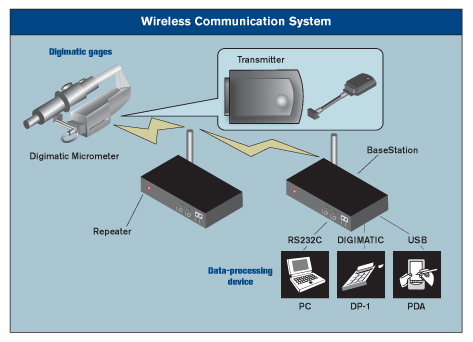

Taking wireless communication to another level, Mitutoyo America Corp. (Aurora, IL) has created a two-way transmission for its digital micrometers and calipers that sends data in two directions over long distances through the use of a new technology the company calls "repeaters," says Bill Wilde, Mitutoyo's marketing manager.

The signal of the bi-directional system has moved from the megahertz range into the gigahertz range to give a clearer signal and eliminate the interference of the electronic emissions given off by machine tools on the factory floor, but because of FCC regulations, Wilde says the power of the bi-directional system is limited so as not to interfere with cellular phone signals, or ambulance or police radios. He says the transmitters can send signals about 60 feet, so repeaters were created to relay the signal. The signal then goes through a series of repeaters until it gets to the database.

Wilde says that until now, an operator would take measurements, hit a button to send the data, but not be sure that the data was getting collected. "Now we have a feedback system, so when the operator hits the button, the information may go through two or three repeaters over a couple hundred feet in a factory, and he'll get a signal back that it was accepted," he says.

Wilde adds that the bi-directional system will help increase productivity. He says that in today's job market, one person may be doing the same amount of work that two or three people once did. Because of the increased workload, an operator cannot monitor the data acquisition system or a real-time SPC program to determine whether the data is drifting out of tolerance. "You hit the button and the signal is sent, but you might not find out until later that you missed a few or a whole batch because it didn't get through the noise of the factory-the electronic noise-or for some other reason it didn't get picked up," Wilde explains. "This way there's a signal back that it is accepted, but we're trying to take it a step further to alert the operator as to whether or not the process is right or if it's drifting out of process and quality is starting to go bad."

Wireless communication plays an important role in clean-room environments. The advent of wireless data transmission eliminates the need to bring unnecessary equipment into a sterile environment to take measurements. Signals can be sent through glass to the data collector. Wilde says two-way transmission is particularly helpful in the medical industry where 100% inspection is being demanded as close to real-time as possible. "If a heart valve or a stent is off by a millionth of an inch, somebody's life could be in danger. You can't wait until you've done a hundred of them and then wonder how many are bad."

Tech tips

• Wireless technology means that handheld tools no longer need to be tethered to a computer to operate.

• Several technologies are available for wireless RS232 communications: serial infrared, wireless RS232 transceivers, wireless Ethernet and Bluetooth serial.

• A new, two-way, bi-directional system will alert operators as to whether or not data was received.