Hyperspectral imaging allows us to look deep under the surface of objects. Machine vision, in particular, uses this innovative camera technology and thus paves the way for entirely new possibilities in quality management. This benefits a wide range of industries, such as food and beverages, agriculture, and pharmaceuticals.

Hyperspectral cameras see more than conventional image acquisition devices do—and are even superior to the human eye. This is because these devices can capture digital image data from a very broad electromagnetic spectrum. While conventional camera technology, just as the human eye, only detects the wavelengths of prime colors (red, green, and blue), hyperspectral systems detect hundreds of different wavelengths. The spectrum ranges from ultraviolet wavelengths to long-wave infrared radiation. The advantage of this feature is that it allows revealing of material properties that are actually located beneath the object’s surface and are invisible to the naked eye. This works because certain material properties alter the surface in such a way that these light waves (which cannot be detected with conventional cameras) are reflected differently than in “normal” situations.

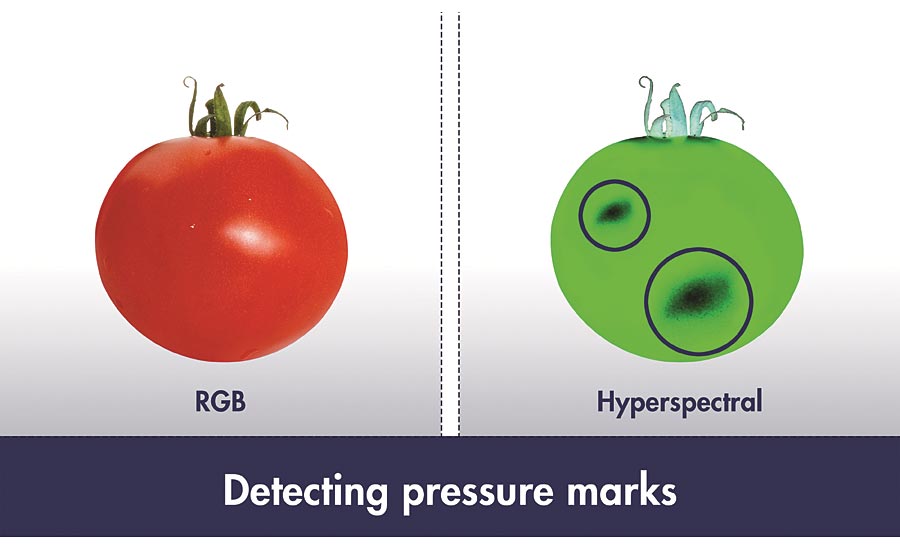

Hyperspectral technology can be particularly beneficial when combined with machine vision. By precisely detecting certain, hidden material properties, objects can be identified and inspected more accurately. Modern machine vision software offers a great many functions for these applications. The particular objects are differentiated through the fine gradation of different gray values. Even the slightest variation in these values points to certain properties, based on which the objects can be clearly distinguished from each other. Moreover, different gray values can also indicate defects or damage. As a result, the technology is virtually predestined for demanding inspection tasks in quality management.

Processing image data step-by-step

Hyperspectral image data is processed in several steps. First, individual pixels are exactly classified using machine vision software. The number of channels does not matter. It is even possible to process image information from hundreds of different wavelengths (channels), because the image data contains the information from all channels. The values of the individual pixels in the corresponding channel are compared with reference data of different classes, which allows the pixels to be clearly assigned to a particular class. The machine vision software then performs another analysis, in which the image data is post-processed with regard to shape or texture. The objects can thus be identified even more precisely based on certain parameters. For example, if they have a similar shape, the texture parameters are used to further distinguish between them, making the recognition rates even more robust.

Due to its ability to “look deep underneath,” hyperspectral imaging, combined with machine vision, is particularly suitable for quality assurance in a wide range of industries, such as food and beverages. For example, the hyperspectral camera can reliably detect hidden layers of mold in food. Fresh meat or processed meat products can be classified qualitatively by determining the fat content or microbial contamination. The quality of fruit and vegetables can also be reliably assessed, e.g., by detecting bruises or worm holes beneath the peel of an apple. This approach makes it possible to automatically remove low-quality fruits before they continue along the value chain.

Detecting pressure marks: Hidden bruises beneath the surface of fruit or vegetables can also be detected with hyperspectral technology. Source: MVTec Software GmbH and Fotolia

Precisely determining quality

Another application of hyperspectral technologies in agriculture is, for example, to precisely determine the ripeness of fruit. This works by detecting color spectra that are transmitted through the skin/peel by nutrients such as sugar and acids. This makes it possible, for instance, to automate the harvesting of apples with robots. Similarly, the technology can also be used for harvesting potatoes. Hyperspectral analysis enables farmers to tell the difference between potato tubers and stones, even though the two are practically indistinguishable. Certain types of wheat can also be sorted according to various quality grades. Finally, hyperspectral imaging is also used in pharmaceuticals, where the technology clearly detects the composition and ingredients of different pills that look very similar on the outside. This ensures that medications with different active ingredients are always placed in the correct packaging. V&S