Home » Keywords: » training

Items Tagged with 'training'

ARTICLES

Management

In my 30+ years working in manufacturing, I’ve seen training approaches evolve significantly.

Read More

Management

The New Workforce Expedition

Building Meaningful Employment Environments.

July 17, 2024

Management

The Urgent Call for Training: Addressing & Actions to Close the Skills Gap

We’ll explore what is causing the skills gap, what training programs we should be implementing, how to start, and how we protect the non-digital skills in a growing digital world.

July 15, 2024

NDT| Training

Quality Training: Advancements, Methods, and Trends

The rise of artificial intelligence (AI) and machine learning has revolutionized the personalization of training programs.

June 14, 2024

Quality Headline

Phillips Joins Precision Metalforming Association as New Director of Technical Training

June 8, 2024

Test & Inspection

The Importance of Quality Assurance and Safety

My training as a nondestructive testing inspector started with mentors that were NDT inspectors during the USS Thresher’s shipyard work.

May 6, 2024

Management

Students and Educators Prove Quality is Never-ending Learning Process

Continuously learning.

May 1, 2024

Management

Five Questions for Dr. Rochelle Cook

Dr. Rochelle Cook of California State University Dominguez Hills describes her route to quality.

April 22, 2024

Quality Headline

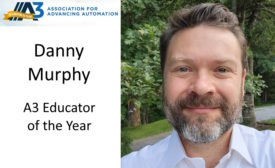

Virginia Professor Danny Murphy Wins Inaugural A3 Educator of the Year Award

April 15, 2024

NDT | Training

The Evolution of NDT Training

Where does the bulk of NDT training responsibility lie, in the classroom or in the field?

March 15, 2024

EVENTS

Webinar

10/18/23 to 10/18/24

Contact: Meg K.

Cut Training Time and Improve Quality With Interactive Digital Work Instructions

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing