Reverse engineering (RE) is the process of converting an actual object into a virtual 3-D model. It differs from the traditional engineering process, which starts with virtual design in CAD, and finishes with a machined, molded, formed or 3-D-printed end product. In contrast, RE begins with a physical object and ends with its deduced design dimensions and shape, for the purpose of maintaining, recreating, adapting or improving this product (or system or assembly). The physical object can be measured using 3-D measurement technology such as CMMs, laser scanners, structured light digitizers, or industrial CT scanning. Once the object has been measured, a RE software will be used in order to convert the 3-D measurements into the final reverse-engineered model.

TECH TIPSReverse engineering has a multitude of applications. It could be used for legacy parts preceding computer technologies, making copies of a unique object, building a scale model, designing an object that must fit around an existing one, or repairing a cast mold for which no digital information exists. Over time, reverse engineering software became capable of manipulating increasingly larger point clouds, thanks to more powerful computer calculation capabilities. Current software versions are capable of handling a large amount of information while providing a variety of tools to perform reverse engineering efficiently. The next evolution in RE software should be related to the intelligence of the software. |

History

Reverse engineering has changed a lot in the last decade or so. At first, the acquisition methods allowed measurement of a limited number of points, which left the designers with some interpretation of the data and high risks of deviating from reality when creating CAD models. Over time, RE software became capable of manipulating increasingly larger point clouds, thanks to more powerful computer calculation capabilities. As a reminder, the hyper threading processor was widely introduced in 2002 and then came the dual cores, then multiple cores and so on. At every evolution of the hardware, the software engineers in charge of RE software could implement new functions that would have been previously impossible to manage for the users, because of the calculation time that they would have involved.

Along with the evolution of computers, scanning systems evolved in parallel and now allow the acquisition of millions of points within seconds, providing much more accurate and complete representations of the measured objects. Of course RE software had to adapt to that new input. Current versions are capable of handling this large amount of information while providing a variety of tools to perform reverse engineering efficiently.

The next evolution in RE software should be related to the intelligence of the software. Following that perspective, the software will analyze the scan data and reproduce the steps that a designer would have performed to come up with a full model, recreating the design intent. To do so, there will be an automatic segmentation of the data and recognition of the CAD operations that led to the design of the model. Improvements are still ongoing, but the approach is very promising.

Main Applications

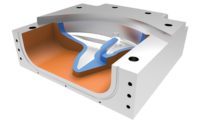

Reverse engineering has a multitude of applications. It could be used for legacy parts preceding computer technologies, making copies of a unique object, building a scale model, designing an object that must fit around an existing one (for instance, a smartphone case or car accessories), or repairing a cast mold for which no digital information exists. Here is one example:

For this specific case, a heavy machinery manufacturer wanted to integrate new equipment on a tractor track frame. First the whole tractor was scanned (see the scanning process in Figure 1, as well as the resulting 3-D image in Figure 2). In this specific case, RE was performed with a high level of details for interfacing zones, and with lesser details on the whole tractor for sizing/footprint.

The surface was then reconstructed into a CAD model that could be used for retrofitting the new equipment.

Concepts

Premise

RE could alternatively aim at recreating the original design intent—if a part is deformed, this must not be represented on the final model, or recreating the object as-is—an object’s imperfection would be reproduced as such.

Real-life mechanical components are almost never as straight as their CAD model counterpart. Since RE starts will the actual object, faces that should be parallel per design are not, or wheel hub axis that should be aligned might be off by a few degrees. Design intent RE will straighten the faces and axes according to the intentions and production method.

As-is reconstruction will reproduce the part in its actual state as faithfully as possible, including all deformations the component, mold or tooling has endured.

Reverse Engineering Methods

There are several types of RE methods; here the most common ones.

Parametric Modeling: features CAD-like operations that create controlled surfaces (for instance, sketch, extrusion, revolve, sweep, loft) and correct any imperfection. Parameters are used to define geometric shapes; dimensions from the shape are extracted from the 3-D image. Operations defining the surfaces are linked to one another; if one variable is modified, all the other ones linking to it will be changed as well. This reconstruction technique is used for design intent-type engineering parts. Since it creates geometrical shapes, it makes the modifications/iterations that are inherent to the design process quick and easy. It is oriented toward design intent.

Surface Modeling: uses many similar operations as the parametric, while allowing more freedom. It uses measurement points from a 3-D image to define complex geometries. Surface imperfection and textures will not be reproduced. It is very difficult to modify, since no parameters define the surfaces. Often used for aesthetic surfaces, such as car bodies. It is oriented toward both design intent and as-is.

Freeform Modeling: uses operations creating surfaces that closely match the 3-D image, including imperfections, small surface detail and texture, if any. For this method, scans must be as representative of the part as possible before creating the model. Although this method offers many tools enabling fitting control, the final result often presents a non-structured surface layout. The end result is very far from a structured parametric or surface CAD reconstruction; this is why it is mainly used on irregular organic shapes such as historical artefacts, plants, rocks, fossils. It is oriented toward as-is RE only.

In short, the method is largely determined by object type and the final RE need. Reconstructing an object can be done through blending a few methods.

Workflow Acquiring Data

This step consists in taking a 3-D image of an object. A 3-D image is defined by a multitude of measurement points determined by the 3-D coordinates, just like the pixels of a 2-D image taken with a camera.

There are a variety of technologies for digitally acquiring the shape of a 3-D object. A well-established classification divides them into two types: contact and noncontact measurements methods. Many products fall under each of these categories.

Noncontact

These technologies project light or radiation to assess the surface of an object. Among these, which include handheld and fixed devices, the most commonly used are laser triangulation, white light, and blue light. The main benefits of noncontact technologies as a whole is that they offer a much higher density of measurement points, and can be used to scan parts that cannot be touched. As a drawback, the very high data volume makes post-treatment longer.

Contact

This type of technology consists in taking measurement points by physically touching the part, through a probe. A few examples of these devices: CMMs, measuring arms, laser trackers and optical CMMs.

Their main benefits: these devices make it possible to scan any type of surface finish without preparation (for instance, glass). They sometimes can be more precise than non-contact solutions. They can access very small, constrained areas (there is no need to see the surface). Their main drawbacks are that the point density is much lower, and interpreting results is more difficult.

It is possible to use several devices at once. Choosing a measurement device (or a few) is mostly related to the shape and dimensions of the object, as well as the desired level of detail and precision during the RE.

Preparing the RE

Parametric and Surface Modeling

Aligning the raw data. This enables combining different measurement point sessions from the same device (different point-of-views for fixed equipment, object that had to be moved) or combining data from different devices. Certain devices perform automatic alignment, making this step unnecessary.

Lighten the number of points. Mainly, this consists in erasing superfluous data, and reducing the measurement point density according to the level of details dictated by the object.

Aligning reference geometric elements with the coordinates system (for instance the support plan or the production reference). This step is very important for parametric RE; if possible a symmetry plane will be used for the alignment. The XYZ are often used as sketch planes for reconstruction operations.

The reconstruction can start; it consists of rebuilding the part through CAD operations.

Freeform Modeling

The raw data also needs to be aligned. However, all the important areas have to be scanned. Using a symmetry plane or extrapolating the surface is quite limited in this case, since the 3-D image has to represent the actual object as faithfully as possible.

Cleaning measurement points to obtain a model that is as close as possible to the final one (surface imperfections, surface boundaries). Several tools can modify the model (smooth the surfaces, cut with planes, engrave a logo, etc.). The surface must be as clean as possible.

The model needs to be aligned with the origin and XYZ axis.

The reconstruction can start; it consists of creating curves projected on the 3-D image that will delimit the patches defining the surface.

File Types

File types can be organized in two categories: measurement points and 3-D model.

Measurement Points

Raw data is extracted from the acquisition. Represent the surface through a multitude of points expressed in a coordinates system. Here are two commonly used measurement point formats:

Point cloud

3-D scanners automatically measure a large number of points on the surface of an object, and often output a point cloud as a data file.

Point clouds are rarely used in most 3-D applications since their visualization is more difficult. Therefore, they are usually converted to “polygon mesh” triangle mesh models. See Figure 4.

Polygon mesh

A polygon mesh is a collection of vertices, edges and faces that defines the shape. The vertices are extracted from the measurement points. The most common formats are OBJ and STL. This makes visualization easy, with a lower point density. These file formats are supported by many other software packages. See Figure 5.

3D Model

In this case, the object surfaces are defined through mathematical equations.

CAD data exchange

These files are compatible with most CAD software programs on the market, and used to exchange files between the different CAD platforms. IGES and STEP are two format examples. These files are supported by nearly all CAD software, and contain all information related to the geometry. These files are difficult to edit, and feature no design tree. A “Dead” solid or surface is obtained. See Figure 6.

Native CAD

3-D files created within specific software are called Native CAD. In general, native formats are optimal for each CAD suite, since they contain all the information generated by a CAD software program. The native format will keep the design tree as well as all the information related to the 3-D model (material, 2-D sketch) Some software can read other native formats.

Software

When it comes to RE, software combines two different schools of thought: CAD software vs. 3-D scanning software. Some software programs are dedicated to 3-D design and modeling and contain reverse engineering tools, while other programs have been developed specifically to handle scan data post-processing and reverse engineering only.

The two main types of software programs are RE software with CAD functions, and CAD software with RE functionalities.

RE software with CAD functions: Among the RE software programs that offer organic surface reconstruction, some will also include CAD-oriented tools for completing parametric and surface reconstructions. They are not as powerful as the tools found in the leading dedicated CAD software, but they do rival with many standard CAD. They make it possible to perform hybrid reconstructions for both organic and manufactured shapes.

Among their benefits, their 3-D scan data post-treatment tools are much more complete, and they are better adapted to manage scan files. They are, however, more limited in their CAD features. These software programs are probably best for companies that frequent work RE projects, especially ones that are both large-scale and complex.

CAD software with RE functionalities: CAD software existed long before 3-D scanning became accessible. Now that the two technologies are used side-by-side, CAD software designers adapted their offering by adding modules for working with scan data within their products. These modules make it possible to load scan files and work. Possible operations include creating sketches on cross-sections, fitting basic geometrical shapes, extracting extrusion or revolving axis, etc. Once all the information from the RE module is loaded in the CAD standard interface, users can reconstruct the part.

CAD software programs offer more complete solutions, at competitive prices. As a drawback, they are less suited and powerful for performing RE and post-treatment. This type of solution is optimal for people wanting to continue working with the CAD program they are familiar with, and for CAD designers who only do RE occasionally.

In the last few years, a new trend had emerged: using both software types simultaneously. This enables working with the best tools in each software for cleaning, merging, generating freeform surfaces and transferring information to the CAD software. Some post-treatment software providers also created bridges between the two software programs, which can transfer all kinds of information or operations. This method brings out the strengths in each software, but can be costly.

A good RE software should be able to extract exact surfaces from a scan, but also have very powerful surface creation tools (malleable, controllable, etc.) for both CAD and parametric surfaces.

No single software can treat every type of surface with the same efficiency and ease; the application will mostly determine the choice of one over the other.

The price range between the different programs can be very wide: higher-end software will provide more sophisticated tools, and a better user experience. However, less expensive software could be perfectly suited for a company with repetitive, targeted, moderately complex applications.

Conclusion

In short, there is no such thing as a perfect RE software. Some kind of a hybrid method is probably the best solution. Each software program has its own strengths, and they are all powerful in their own way. The main thing to remember: what do you need to do with the 3-D measurements?

Will it be 3-D printed? Parametric reconstruction in CAD software? As-is redesign? Will the scan data be used to design something that will interface with your original object? Many factors could influence the choice of a RE software program, including the type of parts to be reconstructed, the frequency of use, and the budget.

What will be the future of RE software? Currently, the process includes a lot of manual operations, with little artificial intelligence. As mentioned earlier, a trend toward automation could make RE a lot more powerful and effective.