The QC-300 performs a QC inspection on a circuit board. During process control, operators can use image archiving to store key part data and text to ensure the part is being manufactured according to specifications and also input their own comments regarding any defects. Source: Metronics

While it is useful to have many special features, it is important to make sure they do not get in the way of functionality.

That was the thinking behind the Quadra-Chek 300 digital readout system with video edge detection and image archiving, which allows operators to store snapshots of video images with part measurement data and user notations.

Metronics started developing the product about two years ago, and has released several versions, each with different capabilities, including one with an optical edge detector for optical comparators.

“The customers love it because it’s simple to use-not a lot of options that they can get lost in,” says Robert Pater, technical services manager at Metronics (Bedford, NH). Unlike a PC system, where menu options fly in and out, the QC-300 aims for simplicity.

The QC-300 was designed for measuring 2-D geometric features and height, and can be used with inspection tools such as measuring microscopes and video systems.

The creators of this touch-screen metrology product know that measurements are not the end of the process. “After you do the measurement, it’s also about getting the data,” Pater says. Therefore, the QC-300 has several interfaces to computers and other external devices: USB ports for computers and printers, an RS-232 port for serial communication and an I/O port for interfacing to light sources and zoom lens controllers. The video edge detection option comes with BNC and S-Video connections for video cameras in NTSC and PAL formats.

Pater says that industry products run the gamut from simple readouts to complex software. The QC-300 fills a niche in the market between digital readouts and PCs. The product combines high-level functions normally found in PCs with the easy-to-use readout format.

“It’s a simpler way to do things, and with video edge detection, you remove operator subjectivity on feature measurements,” Pater says, “but it’s still basically a digital readout-not a PC-not a system that the IT guys have to take care of.

“It’s pretty straightforward,” Pater says. “It can record programs, measure items, and do a simple tolerance report. With video edge detection and image archiving, if you have a problem with a feature on a part, you can snap an image of the feature, add measurement data and even make notations. That image can be stored in the readout, sent to a PC, saved on a USB stick or you can print it out.”

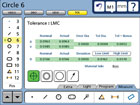

The QC-300 applies a tolerance to a feature. Source: Metronics

The QC-300 digital readout system is a step above the QC-100 and QC-200 Series, though it is not quite as high-powered as the PC-based QC-5000 system. The QC-300 Series has an 8.4-inch color LCD touch screen and SVGA (800 x 600) resolution, along with video edge detection for semi-automated point entry and direct live video input. For manual point entry, there also are several crosshair formats included.

If people are upgrading from older systems, Pater says putting the QC-300 on the system is a relatively inexpensive way to get the system working again.

Metronics aims to meet customers’ need for a basic system with good value. The current version starts at $2,600, but goes higher depending on features and capabilities. With the various types of consumer and industrial devices using LCDs, such as cell phones, prices have come down, Pater says, which allows the color touch-screen display to be included in a system without an exorbitant price.

The new product is not without disadvantages, though. Designed to fit into small areas, some customers have balked at the size of the touch screen and want to hook up a larger monitor, Pater says. However, he points out that a larger screen does not add to accuracy.

The QC-300 when combined with a toolmaker microscope and a camera, Pater says, is basically a low-cost vision system. Video edge detection allows operators to capture an image of what the camera sees, document dimensions, add comments and output that to a USB drive. This can be used to build an image book, and operators can use the captured images to show others what to look for.

Video edge detection in a footprint this small is exciting, Pater says, particularly because of the touch-screen interface. “Anyone with metrology knowledge can easily learn to use this system,” Pater says. “The QC-300 can measure and tolerance features, display the data cloud and create a report.”

When choosing between PC-based systems and digital readouts for metrology applications, companies need to consider the measurement and reporting requirements, the operating environment, the expertise of the operators using and programming the equipment and pricing to obtain the best overall value.

Specifications

- LCD: 8.4-inch color touch screen SVGA

- Resolution: down to 0.000004-inch or 0.0001 millimeter

- Operating temperature: 0 to 45 C

- Enclosure (W x H x D): 11.5 by 7.5 by 2.75 inches

- Base (W x H x D): 10 by 2 by 7.5 inches

- Enclosure weight: 3.5 pounds

- Base weight: 7 pounds

- Input voltage range: 85 VAC to 264 VAC

- Input frequency: 43 to 63 Hz

Technology Contact

For more information on the QC300, contact:Metronics

30 Harvey Rd.

Bedford, NH 03110-6818

(603) 622-0212

[email protected]

www.metronics.com