Digital transformation is a competitive technology and business strategy that leverages data gathering to drive business efficiencies, new revenue growth, and new business models. It is a strategy being adopted by companies of all sizes and geographies. It is particularly useful to manufacturing companies that use data to monitor and adjust processes, improve quality, increase service efficiencies, and increase productivity.

One driver of this transformation is the availability of low-cost data storage and processing power on cloud platforms such as Microsoft Azure and Amazon Web Services. These pay-as-you-go service platforms have eliminated the need for companies to build and manage their own data centers. Most modern corporate management software systems, such as enterprise resource planning (ERP), are now cloud-based, which facilitates integration of additional cloud-based technologies.

Another big driver is the rapid growth of the Internet of Things (IoT). According to industry analyst Gartner, there will be over 20 billion “things” connected to the internet by 2020 (www.gartner.com/newsroom/id/3165317). Internet connected devices on the factory floor used to consist of simple temperature or vibration sensors sitting on a motor. A trend toward edge computing, which is processing data close to the source, is leading to the development of complex quality measurement systems that are integrated into production lines. This serves to minimize data traffic and increase real-time data processing.

Digital transformation also considers how we will use the data collected. Early quality systems were isolated, and often just activated a light pole and simple sorting device. Now smart systems are able to talk to each other, and deliver information to computers, tablets, and mobile devices being used by workers of diverse backgrounds.

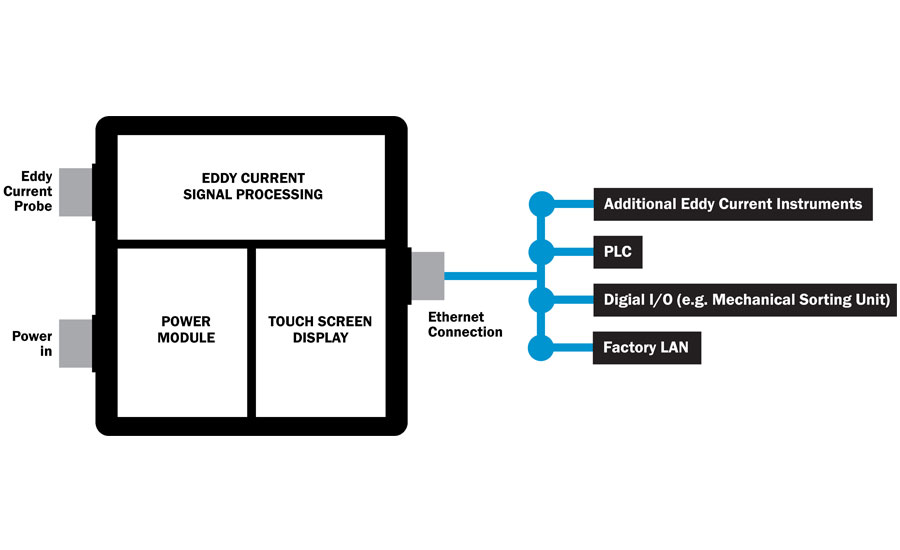

Figure 2. Connectivity of an Eddy Current Device

Impact on Eddy Current System Design

What does this have to do with eddy current testing? To answer that question, look at some of the first eddy current systems used for production testing. These were analog-based systems that used analog circuitry to find material anomalies. These systems lacked the ability to integrate with a light pole or PLC, and they may have had only a simple alarm output for I/O switch closure used to activate a sorter on a production line.

Now fast forward a few decades. Today’s eddy current instruments use digital circuitry, both to create the eddy current drive signals and to process the return signals. High-speed digital signal processing (DSP) circuits, coupled with dedicated microprocessors, make it easy to create and process multi-frequency inspections at production line rates. In addition, test results can be recorded and associated to each manufactured component, providing part-to-part quality accountability. Most importantly, modern eddy current units can be connected to the Local Area Network (LAN), allowing managers to capitalize on the data and be more responsive to production issues as they arise.

Eddy Current Instrument Connectivity

A simplified block diagram of a modern connected eddy current instrument can be seen in figure 2. The instrument can operate as a standalone unit, or be connected to share data—such as eddy current signals, test parameters, alarm status—in various ways. Connection to the factory LAN can occur via Ethernet, wired or wireless. The data can also be delivered to a PLC on the production line, while discrete I/O connection can be used to drive mechanical sorting units.

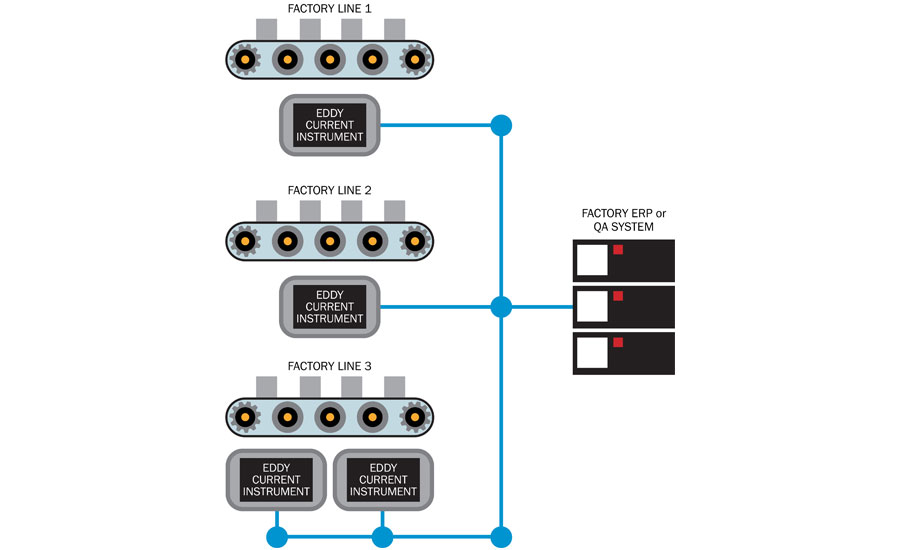

Figure 3. Eddy Current Factory Installation

Multiple devices can be linked together to serve as a multi-channel eddy current system. The individual devices can also be spread across a production line or the entire factory and interconnected via factory Ethernet. In addition, all the data can be stored and processed in the factory quality or manufacturing systems. Figure 3 shows a factory setup with single eddy current instruments on two lines, and multiple eddy current instruments on the other line.

Network Requirements

Devices on the factory floor are typically connected using dedicated “real-time” LANs. Connections may be made via wired Ethernet, wireless Ethernet, or other physical layer protocols. Such LANs are partially or fully isolated from other networks, in order to fulfill real-time networking requirements. Here are key requirements for a real-time network:

1. Reliability. Isolating the network from other networks reduces the possibility of outside network traffic or external system failures affecting the reliability and performance of the private real-time network.

2. Guaranteed minimum real-time latency. Introducing network traffic from other sources can cause communication delays with an open-ended latency, i.e. the worst case delay cannot be predicted. It is also important to configure the network in full duplex mode, data transmitted in both directions at the same time on the same line (using switches instead of hubs, etc.), in order to avoid messaging collisions that cause indeterminate latency.

3. Security. The corporate IT department typically isolates their “corpnet” from the factory floor. This can be accomplished by complete isolation, or by using a proxy server to carefully filter traffic between the corpnet and the factory floor real-time network. Perhaps even more important is partial or full isolation from the public internet.

User Experience/Interface

As digital transformation drives an increase in system complexity, and the factory workforce increases in diversity, it becomes critical to create easy-to-use and easy-to-implement systems. User interfaces must be designed for multiple users of varying ability.

Conclusion

Digital transformation and IoT are driving changes in how eddy current testing systems are being designed and implemented. Eddy current and other instrument developers are focusing on communication, modularity, data processing and ease of use when developing new systems. This will enable factories to increase their standards of quality, and drive efficiencies and revenue growth.