Home » Keywords: » automation

Items Tagged with 'automation'

ARTICLES

Quality Headline

A3 Unveils Advocacy Principles to Accelerate Robotics, Automation Adoption Across U.S.

April 18, 2024

Quality Headline

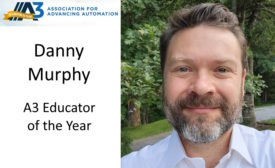

Virginia Professor Danny Murphy Wins Inaugural A3 Educator of the Year Award

April 15, 2024

New Product

Kitov.ai Software Platform for Improved Automated Visual Inspections

March 18, 2024

Quality Headline

Onto Innovation 4Di InSpec Automated Metrology System Receives 2024 Innovative System of the Year Award from FANUC America

February 28, 2024

Vision & Sensors | Machine Learning

Machine Learning for Automation & Quality Inspection

While machine learning is a subset of AI, deep learning should be viewed as a subset of machine learning.

February 5, 2024

EVENTS

Webinar

7/27/23 to 7/27/24

Contact: Meg M.

Why Cobots Are the First Choice for Many Small to Medium-Sized Companies

Webinar

4/18/24 to 4/18/25

Contact: Meg K.

Focus on What Matters: The Future of Digital Precision in Manufacturing

Webinar Sponsored Webinars Sponsored

5/22/24 to 5/22/25

Contact: Meg K.

Quality Automation: How Robotics and Sensors Drive Quality Control and Production

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing