Home » Keywords: » LEDs

Items Tagged with 'LEDs'

ARTICLES

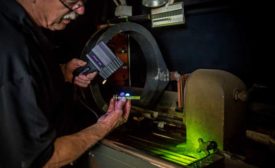

LED Light Pulses Enter the Nano Realm to Keep Pace with High-Speed Imaging

A competent vision designer can optimize image capture at extremely high speeds.

May 4, 2020

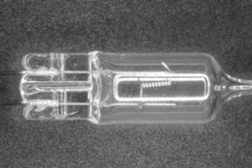

NDT Compliance: The Proper Test for High Quality Lamps

Standards are constantly getting upgraded to make NDT safe and reliable for inspectors and the public.

November 8, 2019

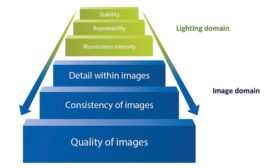

The Importance of Consistent Illumination in Machine Vision

Machine vision systems evaluate the image of the object, not the object itself, so the first stage in the process is to get the correct lighting arrangement for the application.

January 1, 2017

Measurement

How to Choose the Right Lighting for Machine Vision Applications

“The most sophisticated automated inspection system in the world cannot work without the proper lighting.”

October 3, 2013

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing