Home » Keywords: » electric

Items Tagged with 'electric'

ARTICLES

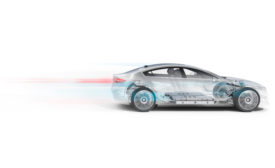

Intelligent factories, electric vehicles and traceability are just some of the factors that are influencing change in automotive part inspection, say experts in the field.

Read More

Introducing E-Mobility Inspection

Meet the quality inspection solutions for all components of E-Mobility: Battery, Power Electronics, E-Motor and Transmission.

January 2, 2020

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing