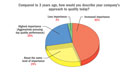

The importance of quality

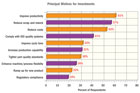

The need for quality in manufacturing is as strong as ever. Forty percent of survey respondents said that their company’s approach to quality today has increased in importance compared to three years ago. Twenty-eight percent said that it is of highest importance and that they are aggressively pursuing top-quality performance. This is an increase from last year, when only 25% said it was of highest performance.Actual 2006 spending for equipment, software and services compared to their original estimates shows that most companies stayed on budget. Seventy-eight percent said that their 2006 numbers were the same as they had estimated. The average company budget for 2007 is expected to see a slight increase among those who expect to spend more in the upcoming year. Twenty-five percent said they expect to increase their spending on quality in 2007 when compared to 2006.

Software use rises

One of the biggest leaps and brightest signs for 2007 is the forecasted spending increase for software. In 2007, sales of quality software are projected to reach $741.2 million. Leading the way is calibration software. In 2007, calibration software is estimated to be $116.1 million, or 16.4%, of a company’s budget for quality software. Data collection software is expected to be the second most common software expenditure-more than $87 million is earmarked for it. Data collection software will account for 12.3% percent of the average software budget.Document control and management software will be the third most often purchased software in 2007 at $80 million in projected spending.

A sizeable increase in coordinate measuring machine (CMM) programming and simulation software is expected for 2007. It will account for $68.4 million in projected spending.

ISO-related software will still be an important investment during 2007, projected to garner $65 million in sales.

Finally, statistical process control software remains important to manufacturers as they tellQuality Magazinethey will spend $41.6 million on it during 2007.

Services stay stable

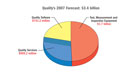

After a very strong 2006-projected forecast in quality services, overall quality services are forecast to remain at those levels. Quality services include consulting and training, representing 58% of expenditures, and test, measurement and inspection services, which account for 42% of planned expenditures.Twenty-five percent of manufacturers expect they will spend $25,000 or more on quality services. The average that plants will be spending in this category in 2007 is $25.1 million.

An estimated $581.5 million is expected to be spent during 2007 on quality consulting and training services. The biggest expenditure in this area remains certification and registration with a 2007 forecast spending of $220.2 million.

Among the various services manufacturers will budget for in 2007, calibration services continue to lead spending, outpacing contract part inspection, lab testing, and prototyping and reverse engineering. Calibration services’ 2007 projected forecast of $272 million makes up 27.2% of all quality service expenditures.

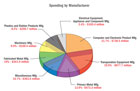

Equipment spending stays healthy

Spending on test, measurement and inspection is expected to top $1.67 billion during 2007. Leading equipment expenditures include handheld measuring tools at $205 million, coordinate measuring machines at $177.4 million, calibration equipment at $133.2 million, thread gages at $74.8 million and environmental test equipment at$47 million.

As has been the trend the previous two years, gages and gaging systems will make up the largest category of spending at $619 million. The leading expenditure among these devices includes handheld measuring tools, projected to reach $205 million. Fixture and special tooling gages will reach $67.5 million, and plug and ring gages will account for $56 million during 2007.

The optical inspection and measurement category, now including sensors and videoscopes, is to see increased spending. These two new categories will see manufacturers spend $14 million and $9.5 million, respectively.

Overall, materials test equipment will constitute $165 million, or 9.9%, of manufacturers’ equipment budget

in 2007.

On top, hardness testing represents $43.4 million of respondents’ equipment purchases. Tensile testing represents $28.5 million of respondents’ equipment purchases and chemical analysis, spectroscopy, represents $22.2 million of their equipment purchases.

Quality Magazinewas able to determine projected spending on four types of materials test equipment that had been difficult to measure before now.

Nondestructive test (NDT) equipment continues to enjoy healthy spending during 2007 and will account for a good portion of 2007 equipment purchases. Top NDT equipment purchases include X-ray equipment, $28.6 million, ultrasonic test equipment, $22.6 million, magnetic particle inspection equipment, $14 million,

dye penetrant testing, $12 million, and electromagnetic testing equipment, $9.3 million.

Survey methodology

Quality Magazinewould like to thank all the respondents who participated in the 7th Annual Quality Capital Spending Survey. Questionnaires were mailed from July through August 2006 to managers and other professionals who have responsibility for quality and who hold the highest degree of equipment purchasing influence in a representative sample of 5,000 plants. Respondents were asked to share their spending plans for 2007. The cutoff date for responses was August 28, 2006.

Quality Tech tips

- Equipment, software and services spending will be $3.4 billion in 2007.

- $1 billion is earmarked for quality services.

- Software spending continues to increase during 2007 and is estimated to be $741.1 million.

- Pre-9/11 spending increases continue during 2007.