Since 1850 we have known that metal subjected to fluctuating stresses will fail at a stress much lower than required to cause fracture on a single quasi static pull to break. Failure usually occurs without warning and results in a brittle appearing fracture with no significant deformation. Metal fatigue is a multi-step process and is often described as having four stages.

Stage 1: Crack Initiation: A part becomes damaged as a micro crack forms at a point of high stress concentration. High stress concentration points are usually located at notches, sharp edges or corners. Annealing is used to repair metals damaged in stage 1.

Stage 2: Slip Band or Stage 1 Crack Growth: The initial crack deepens on planes of high shear stress and becomes well defined.

Stage 3: Stage II Crack Growth: The well-defined crack grows in a direction normal to the maximum tensile stress.

Stage 4: Ductile Failure: When the crack reaches a critical length, the remaining cross section cannot support the applied forces and the part fails.

Cycle Testing

Fatigue tests are most frequently carried out under stress based constant amplitude loading. Test samples can be subjected to a variety of waveform geometries, however, sinusoids are most prevalent. Figure 2 depicts a stress based sinusoidal waveform showing fully reversed stress cycles. The maximum and minimum stresses are equal and opposite in a fully reversed cycle test. By convention compressive stresses are negative.

Most stress based fatigue testing is conducted using fully reversed loading. However, many examples exist where fully reversed loading is not performed either because it is not possible or during normal service a component is only subjected to forces in one direction. Examples of repeated stress cycle loading include compression only fatigue tests on hip implants and tension only tests on sheet steels (thin materials buckle in compression).

Waveform Properties

The following definitions and equations are used to express a stress based waveform. (Refer to Figures 2 and 3 for further explanation.)

Stress Range, Sr, - difference between the maximum and minimum stress.

Sr = Smax - Smin

where, Smax = Maximum Stress

Smin = Minimum Stress

Stress Amplitude, Sa - one half of the Stress Range, Sr.

Sa = Sr/2 = (Smax-Smin)/2

Mean Stress, Sm- average of the maximum and minimum stress.

Sm = (Smax + Smin)/2

Stress Ratio, R – equals -1 for fully reversed loading.

R = Smin/Smax

Amplitude Ratio, A – infinite for fully reversed loading.

A = Sa/Sm = (1-R) / (1+R)

Force Application

Most fatigue tests are conducted by applying fluctuating bending forces, axial forces or torsional forces to a specimen. The formulas for calculating stress for each mode of loading is as follows:

Bending Stress

The maximum bending stress occurs on the surface of the specimen where c is greatest.

Sbending = Mc/I

where, M = Moment (force x distance)

c = distance from neutral axis to a point

I = moment of inertia (formula based on shape of specimen, round = pR4/4)

Axial Push-Pull Stress

Saxial = P/A

where, P = Axial Force

A = cross sectional area of specimen.

Torsional Stress

The maximum torsional stress occurs on the surface of the specimen where r is greatest.

Storque = Tr/J

where, T = Torque (force x distance)

r = distance from center to a point

J = polar moment of inertia (formula based on shape of specimen, round=πR4/2)

Stress Life Testing

Between 1852 and 1870, the first systematic fatigue tests were carried out on specifically designed laboratory specimens by August Wohler, a German railway engineer. These tests enabled Wohler to relate his experimental results to the stresses in locomotive axles. In 1870, Wohler compiled a report of his experimental work which contained several conclusions known as Wohler’s laws.

Wohler’s Laws (1)

Materials can be induced to fail by many repetitions of stress, all of which are lower than the static strength.

Stress amplitudes (or stress range) are decisive for the destruction of the cohesion of the material.

The maximum stress is of influence only in so far as the higher it is, the lower are the stress amplitudes (or stress ranges) which lead to failure. This translates to increasing the mean stress decreases the number of cycles to failure.

Stress life testing is based on Wohler’s work and requires multiple constant amplitude fatigue tests on identical samples to generate an S-N or Wohler diagram. Figures 4 and 5 are diagrams of Wohler’s fatigue testing machine and the S-N diagrams for the steel used in the axels, respectively (2). Stress life testing is the most common type of fatigue testing and is designed to determine the safe or infinite life or fatigue strength of a material or component.

The S-N or Wohler Diagram

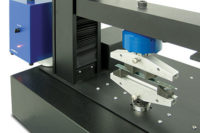

In stress based fatigue tests, multiple samples of identical size, shape and composition are subjected to different levels of stress amplitude, Sa, or stress range, Sr, and the number of cycles to failure, N, is measured for each. Various types of instruments and machines are used to apply cyclic loading and include rotating bend and cantilever bend machines (Figure 7), servo-hydraulic or servo-electric axial push-pull testing systems (Figure 8), and electric motor driven torsion fatigue testers (Figure 9). The resulting S-N data for each identical specimen is plotted on either a log-log or semi log graph. Regression is used to fit a curve through the points resulting in an S-N diagram as shown in Figure 6. Depending on the type of cyclic loading the ordinate (y-axis) will represent stress amplitude, Sa, stress range, Sr, or maximum stress, Smax.

The S-N diagram for some materials including steel and titanium transitions to a zero slope at a particular stress level. As shown in Figure 6, the point at which the slope transitions to zero is referred to as the endurance limit. Materials subjected to stresses below the endurance limit will never fail under cyclic loading. The portion of the curve with negative slope is defined as the finite life region and the horizontal or zero slope portion of the curve is the infinite life region.

Many non-ferrous alloys such as aluminum and copper and composites such as fiber reinforced plastic exhibit an S-N diagram with negative slope only. Negative slope S-N diagrams have no definite endurance limit (see the aluminum S-N diagram in Figure 6). Materials exhibiting S-N diagrams without a definite endurance limit, report fatigue strength as a stress below which failure will not be expected in less than a specified number of cycles. The fatigue strength or effective endurance limit for these materials is sometimes defined as the stress that causes failure at a specified number of cycles (i.e. 108).

Variability of Fatigue Data

Fatigue can be characterized as a random process which results in a scatter of the test data. This variability complicates the analysis of the data and its subsequent use in real-life applications. Statistical methods are employed to determine the most efficient use of a limited number of test specimens required to give a specified degree of confidence in the results. These methods are used to aid in the selection of discrete stress levels and number of tests to be performed at each stress level. Also important is whether the test data is for exploratory purposes, for research and development, for design or for reliability. For example, Table 1 of ASTM D3479 Standard Test Method for Tension-Tension Fatigue of Polymer Matrix Composites specifies a minimum number of samples as six for preliminary work, 12 for research and development, and 24 for design and reliability analysis. A review of Chapter 3, Planning S-N and Response Tests, STP-588 Manual on Statistical Planning and Analysis for Fatigue Experiments(3) is recommended for those conducting stress-life fatigue tests.

Waveform Cycle Frequency

A fatigue test specimen is subjected to over 10 million cycles (107) in order to determine its endurance limit or fatigue strength resulting in a single test lasting days and sometimes weeks. As a result, there is an impetus to apply the stress cycle at a high frequency in order to shorten the length of each test. Stress life testing of metals under axial loading is governed by ASTM E466 Standard Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials. ASTM E466 recommends frequencies between 0.01 Hz to 100 Hz (10-2 to 102). However, localized yielding which occurs as a crack propagates through the test piece can cause specimen heating. Metals are good thermal conductors and any energy converted to heat is easily dissipated. Thus, stress-life testing of metals is generally frequency independent. Plastics on the other hand are more likely to be locally heated by high rates of stress reversals due to their inability to dissipate heat. This coupled with their lower melting points can result in lower fatigue strengths at higher frequencies. In general, 5Hz is the recommended maximum frequency for testing plastics. Fiber reinforced matrix composites have tailored mechanical properties which are dependent on the direction of loading relative to the fibers embedded in the composite. The direction of loading relative to the fibers and amount of resin in the matrix are important parameters when considering test frequencies. Higher amounts of resin in the matrix produce greater hysteresis (ie. strains within the resin) resulting in a material more susceptible to heating at higher frequencies. Matrix composite test specifications generally limit the test frequency to 5Hz or less. Regardless of the material, at the start of any fatigue testing regime, temperature should be monitored to ensure it does not affect the results.

A Final Note

The many variables associated with material type, sample geometry and in service use of a part or component complicates the design and implementation of an appropriate fatigue testing regime. Like all fatigue tests, the results are suitable for application to design only when the specimen test conditions realistically simulate service conditions. This article presents the basics to stress life fatigue testing. For those new to fatigue testing and planning to conduct their own tests, the author recommends reviewing the ASTM test specifications and references listed here.

Strain life and fracture mechanics crack growth testing are two alternative types of fatigue tests in wide use today. Each of the three methods are employed for different design reasons. Stress life testing is used for determining the safe infinite life of a component. Strain life testing is used for determining safe finite life and fracture mechanics to measure the damage tolerance of a part.

Partial list of ASTM Stress-Life based Fatigue Testing Specifications

ASTM D3479 Standard Test Method for Tension-Tension Fatigue of Polymer Matrix Composites

ASTM D7774 Standard Test Method for Flexural Fatigue Properties of Plastics

ASTM D7791 Standard Test Method for Uniaxial Fatigue Properties of Plastics

ASTM E466 Standard Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials

ASTM E467 Practice for Verification of Constant Amplitude Dynamic Forces in an Axial Fatigue Testing System

ASTM E468 Standard Practice for Presentation of Constant Amplitude Fatigue Test Results for Metallic Materials

ASTM E739 Practice for Statistical Analysis of Linear or Linearized Stress-Life (S-N) and Strain-Life (-N) Fatigue Data

ASTM E1012 Practice for Verification of Testing Frame and Specimen Alignment Under Tensile and Compressive Axial Force Application

ASTM E1823 Terminology Relating to Fatigue and Fracture Testing.

References

- Les Pook, Metal Fatigue, Springer, 2007, p 9-10

- STP-566 Handbook of Fatigue Testing, American Society for Testing of Materials, 1974, p Preface

- R.E. Little, STP-588 Manual on Statistical Planning and Analysis for Fatigue Experiments, American Society for Testing of Materials, 1975

- M.E. Fine and Y.W. Chung, Fatigue Failure in Metals, Fatigue Fracture, Volume 19, ASM Handbook, ASM International, 1996, p 63-72

- Mechanical Testing and Evaluation, Volume 8, ASM Handbook, ASM International, 2000, p 681-714

- George Dieter, Mechanical Metallurgy, McGraw Hill, 1976, p 403-450

- J.M. Hodgkinson, Mechanical Testing of Advanced Fibre Composites, Woohead Publishing, 2000, p 248-267

- Stephen P. Timoshenko, History of Strength of Materials, McGraw Hill, 1953, p 162-171

- Lee, Pan, Hathaway, Barkey, Fatigue Testing and Analysis, Elsevier, 2005, p 103-180