The advantages of a 2-methods-in-1 materials analysis solution combining optical microscopy and laser induced breakdown spectroscopy (LIBS) for simultaneous visual and chemical inspection are described. The basic principles of the 2-in-1 solution and a comparison between it and other common materials analysis methods, such scanning electron microscopy (SEM), are explained to demonstrate how a rapid, efficient workflow is achieved. A 2-in-1 analysis solution can reduce significantly the cost and time for obtaining material image and composition data. Such data are instrumental in assuring quality and reliability to make confident decisions quickly during production, quality assurance and control, failure analysis, and research and development in industries such as automotive and metallurgy.

A large number of products and applications require materials analysis. Examples are found in the metal alloy, automotive, aerospace, and electronics industries [1,2], as well as the fields of metallurgy/metallography [3,4], earth science [5], and materials science. Finding a balance between the need to ensure product quality or reliability of research results and the cost of analysis becomes a serious concern.

Much time and money is spent using multiple techniques, such as optical and scanning electron microscopy (SEM) along with energy dispersive spectroscopy (EDS). They are used to visually inspect a material, via microscopic image generation with high resolution and sharp contrast, and identify its local composition, via qualitative chemical/elemental spectroscopic analysis. Methods like SEM/EDS require special sample preparation and transfer of the sample into vacuum, which is time consuming, for observation and analysis. In most cases, reliable data for a material’s local morphology and composition are vital for determining a further course of action for the specific application, especially if confident decisions must be made despite serious time and budget constraints.

A solution that offers both precise, reliable visual and chemical analysis in one instrument, requires little or no sample preparation, and operates with the sample in ambient conditions would greatly increase workflow efficiency. Such a device would allow both time and cost savings when doing materials analysis.

A 2-methods-in-1 solution combines optical microscopy (visual analysis) with laser induced breakdown spectroscopy [LIBS] (chemical analysis). The basic operating principles and workflow advantages of a 2-in-1 solution are discussed here.

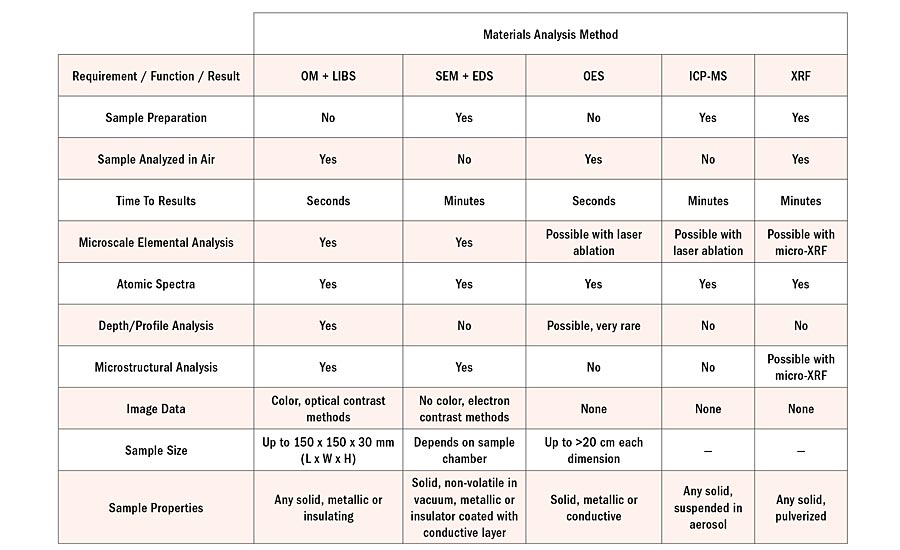

Table 1: Comparison between several materials analysis methods in terms of their operational requirements, analytical functions, and the results delivered.

Basics of LIBS

What is laser induced breakdown spectroscopy (LIBS) and how does it make qualitative elemental/chemical analysis possible?

LIBS was first discovered in 1962, but it was not until the 1980s that it was used to determine the chemical composition of materials [6-8].

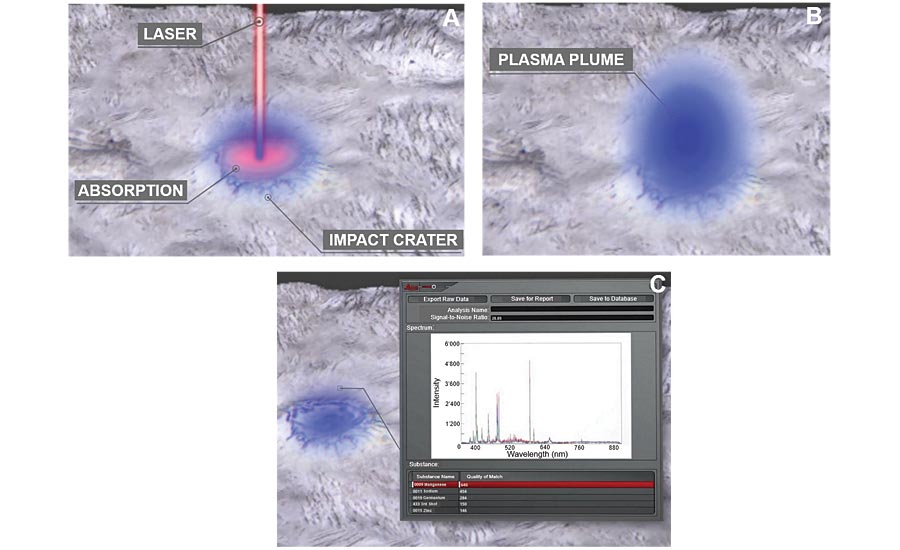

The mechanism of LIBS [7-9], which enables material composition analysis, occurs in several steps:

- A high energy laser pulse strikes a targeted area of the material surface being analyzed (Fig. 1A);

- The laser energy is absorbed leading to local area ablation and crater formation (Fig. 1B);

- A plasma is induced (free atoms and electrons) with simultaneous light emission;

- Plasma breakdown (relaxation) follows immediately with emission of elemental line spectra;

- The spectra are detected and the corresponding elements identified (Fig. 1C).

Figure 1: LIBS mechanism for chemical/elemental detection: A) laser pulse strikes an area of the material, the energy is absorbed, the local material is ablated, and a crater is formed; B) a plasma is induced, followed by its breakdown with light emission; and C) the elemental line spectra are detected and elements identified.

Efficient Materials Analysis Workflow

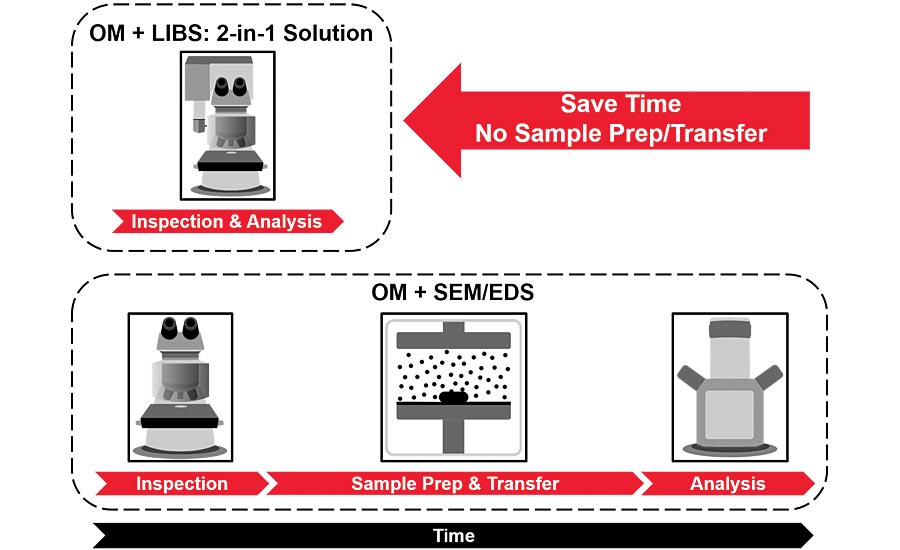

A 2-in-1 solution combining optical microscopy (OM) with LIBS reduces significantly the amount of effort and time required to do the analysis workflow. Why is analysis with a 2-in-1 (OM + LIBS) solution more efficient than optical and scanning electron microscopy plus energy dispersive spectroscopy (OM + SEM/EDS)? Because the most time-consuming work steps are eliminated. With a 2-in-1 OM + LIBS solution, both before and after the initial material inspection, there is:

- No sample preparation before doing analysis;

- No sample transfer from an optical to electron microscope;

- No relocating the region of interest (after sample transfer); and

- No system adjustment (after sample transfer).

All of these steps are typically done for analysis with OM + SEM/EDS [10]. Figure 2 shows graphically the differences between the workflows.

The additional work steps listed above, required for chemical analysis when using SEM/EDS, can be skipped during the materials inspection due to typical restraints on money and time. Still, there is a risk when the material’s composition data is not available: without all the relevant information, it may not be clear what the right decision would be for the next work step or action. Then there is a higher risk of not achieving the targeted product quality.

Comparison of Common Materials Analysis Techniques

At present, the most commonly used methods for materials analysis are:

- Optical microscopy (OM);

- Scanning electron microscopy (SEM) with energy dispersive spectroscopy (EDS);

- Optical emission spectroscopy (OES);

- Inductively coupled plasma mass spectrometry (ICP-MS); and

- X-ray fluorescence spectroscopy (XRF).

These methods listed above, as well as a 2-in-1 solution combining OM with LIBS, have specific operational requirements, analytical functions, and can deliver certain results. Table 1 shows a comparison between the methods. There are distinct advantages seen for a 2-in-1 solution (OM + LIBS).

Figure 2: Comparison of workflows for a 2-in-1 OM + LIBS (optical microscopy and laser spectroscopy) solution and a typical OM + SEM/EDS (optical and electron microscopy) approach to materials analysis. Notice that the preparation and transfer steps in the OM + SEM/EDS workflow are eliminated with the 2-in-1 OM + LIBS solution. The reduction of time-consuming work steps makes it clear why the 2-in-1 solution is more efficient resulting in shorter processing times while maintaining high quality.

Summary

The basic operating principles and advantages of a 2-methods-in-1 materials analysis solution for an efficient analysis workflow were presented. A 2-in-1 solution achieves these benefits by the combination of optical microscopy and laser induced breakdown spectroscopy (LIBS) for simultaneous visual and chemical inspection of materials.

Materials analysis is important for many types of product development, quality control, failure analysis, and technical applications and is used routinely in multiple industries and fields, like transportation, electronics, metallography/metallurgy, and materials science. Often the time and expense allocated for such analysis is limited. However, obtaining reliable results and achieving the desired product quality always remains a priority.

A 2-in-1 solution offers accurate, rapid visual and chemical analysis, eliminates sample preparation and transfer, and does not require the sample to be in vacuum. Either dry or wet samples in air can be analyzed. These advantages enable users to perform fast, precise, and cost-effective materials analysis.

References

- Y. Holzapfel, J. DeRose, G. Kreck, M. Rochowicz, Cleanliness Analysis in Relation to Particulate Contamination: Microscopy based measurement systems for automated particle analysis, Science Lab (Leica Microsystems, 2014). https://www.leica-microsystems.com/science-lab/cleanliness-analysis-in-relation-to-particulate-contamination

- J. DeRose, K. Scheffler, Cleanliness Analysis with a 2-methods-in-1 solution: See the particles and know their composition at the same time, Science Lab (Leica Microsystems, 2018). https://www.leica-microsystems.com/science-lab/cleanliness-analysis-with-a-2-methods-in-1-solution

- D. Diez, J. DeRose, T. Locherer, Rate the Quality of Your Steel: Overview of standard analysis methods and practical solutions for evaluating steel inclusions, Science Lab (Leica Microsystems, 2018). https://www.leica-microsystems.com/science-lab/rating-the-quality-of-steel

- D. Diez, J. DeRose, How to Adapt Grain Size Analysis of Metallic Alloys to Your Needs: Precise and Practical Microscopy Solutions, Science Lab (Leica Microsystems, 2019). https://www.leica-microsystems.com/science-lab/how-to-adapt-grain-size-analysis-of-metallic-alloys-to-your-needs

- M. Hügi, Exclusive Aesthetics of Nature: Inclusions in Gemstones, Science Lab (Leica Microsystems, 2009). http://www.leica-microsystems.com/science-lab/exclusive-aesthetics-of-nature

- L. Radziemski, D. Cremers, A brief history of laser-induced breakdown spectroscopy: From the concept of atoms to LIBS 2012, Spectrochimica Acta Part B: Atomic Spectroscopy (2013) vol. 87, iss. 1, pp. 3-10, DOI: 10.1016/j.sab.2013.05.013. https://www.sciencedirect.com/science/article/abs/pii/S058485471300116X

- S.G. Buckley, Spectroscopy: LIBS comes on strong, LaserFocusWorld (2006) vol. 42, iss. 2, https://www.laserfocusworld.com/test-measurement/test-measurement/article/16546685/spectroscopy-libs-comes-on-strong

- T. Kim, C.-T. Lin, Laser-Induced Breakdown Spectroscopy, Ch. 5 in Advanced Aspects of Spectroscopy, Ed. M.A. Farrukh (InTech, 2012) DOI: 10.5772/48281. http://cdn.intechopen.com/pdfs/38540/InTech-Laser_induced_breakdown_spectroscopy.pdf

- J. DeRose, K. Scheffler, See the Structure with Microscopy - Know the Composition with Laser Spectroscopy: Rapid, Complete Materials Analysis with a 2-Methods-In-1 Solution, Science Lab (Leica Microsystems, 2018). https://www.leica-microsystems.com/science-lab/see-the-structure-with-microscopy-know-the-composition-with-laser-spectroscopy

- G. Höflinger, Brief Introduction to Coating Technology for Electron Microscopy, Science Lab (Leica Microsystems, 2013). http://www.leica-microsystems.com/science-lab/brief-introduction-to-coating-technology-for-electron-microscopy