Home » Keywords: » laser measuring systems

Items Tagged with 'laser measuring systems'

ARTICLES

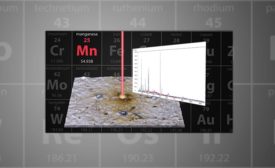

Rapid, Accurate Materials Analysis with a 2-Methods-In-1 Solution

Use microscopy to visualize the structure and laser spectroscopy to know the composition.

December 2, 2019

Sponsored Content

Automated Gap/Flush Measuring System for 100% Inspection

October 30, 2018

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing