Over the past decade manufacturers have increasingly turned to flexible, customizable automation platforms to meet the demands of high mix/low volume orders and ensure their long-term survival in a competitive manufacturing environment.

This trend has seen collaborative robots—low cost, industrial robot platforms designed to work safely alongside humans on a wide range of tasks, including quality inspection—grow from niche product status ten years ago to become an established technology and the fastest-growing segment of the industrial automation market. As these ‘cobots’ prove themselves on the factory floor, the Robotic Industries Association predicts that cobot adoption will jump ten-fold to account for 34% of all industrial robot sales by 2025.

Podcast: COVID-19, Cobots and Quality

Learn how the pandemic is affecting the cobot industry and how manufacturers can best deploy this technology during these challenging times. Joe Campbell, senior manager of applications development at Universal Robots, explains the trends.

While traditional automation systems are ingenious, they can also be expensive and rigid. By contrast, cobots can be assigned to one set of quality inspection tasks in the morning and reassigned to a completely different set of quality inspection tasks in the afternoon. One vision system can be swapped out for another in minutes. And so, traditional ‘one-size-fits-all’ approaches to automation are increasingly losing ground to customizable cobot platforms.

As automation frees itself from its traditional rigidity, vision systems are following suit. The end result is the marriage of a wide range of vision systems with versatile cobot platforms. And as cobot-based systems for quality inspection prove themselves on the ground, they become increasingly preferable to ‘one-size-fits-all’ automation offerings.

Both trends are positive for quality professionals. Cobots are designed to take over dull, dirty and dangerous elements of the job, freeing quality professionals to focus on higher-level, problem-solving skills. Adding robot vision systems to the mix extends that extra freedom to the machine vision realm.

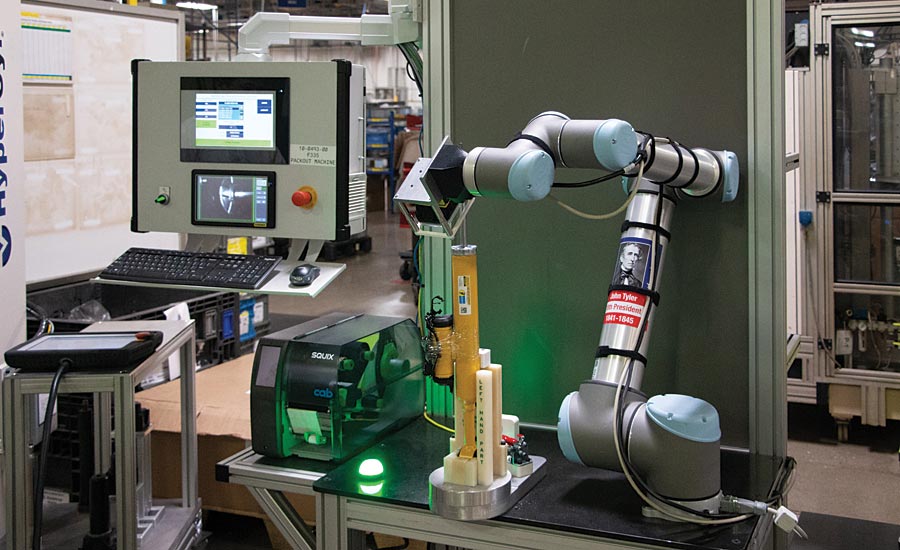

At thyssenkrupp Bilstein in Hamilton, Ohio, a UR10 collaborative robot from Universal Robots is deployed in the Final Assembly Area inspecting thyssenkrupp’s Active Damping System (ADS) dampers. The UR10 is equipped with a Cognex camera and moves swiftly between inspection points to make sure parts are assembled correctly and that labels are applied and readable. Every single part that comes is checked and if it fails, the cobot rejects it in the process.

Quality’s 19th Annual State of the Profession Survey conducted in March of this year, found that two in five companies are using or planning to use robots, and half of those are already training their existing workforce on robot technologies. These preexisting trends have been given extra impetus by the global COVID-19 pandemic. The manufacturing sector is adjusting to new operating conditions, decreased labor availability and increased economic uncertainty. As a result, the demand for flexible automation platforms has intensified.

Machine vision systems are important tools for quality inspection. Offering speed, accuracy and repeatability beyond that of humans, these artificial eyes support a wide range of inspection, measurement and assembly verification tasks. When cobots and customizable vision are combined, manufacturers benefit from improved quality throughput and outcomes. It also becomes possible to quickly adjust quality inspection processes without significant downtime. Meanwhile, quality professionals can enjoy a safer, healthier work environment and more interesting challenges to work on.

When choosing a vision system for quality inspection, it’s important to consider whether it has the power and customization capacity to be put to work on a wide range of tasks.

A simple 2D camera system will facilitate low cost X and Y axis determination, for example, but it will also lack the versatility to support advanced visual inspection. Meanwhile, more expensive 2.5D cameras provide Z axis information. The most expensive 3D camera systems can be used on the widest range of applications, but can come with a hefty price tag.

Then there is the issue of integrating your preferred vision system with your automation platform. Some cobots come with integrated vision hardware, which simplifies the integration process but limits the visual capabilities of the system. It also increases the cost of the cobot and may well be overkill in terms of your application needs. The marriage of open-ended cobot technology with customizable vision systems, on the other hand, blends these approaches to provide quality professionals with no-compromise, application-specific solutions.

Instead of relying on the generic capabilities of in-built vision systems, quality inspection teams can choose cobot platforms that support a wide range of vision technologies to support tasks from pick & place and machine tending to smart 3D systems for vision guidance and quality inspection.

Specialized kits designed to support specific inspection tasks such as small part inspection simplify the process further via a range of hardware and software tools that facilitate end-users quickly setting up and deploying inspection apps. Such systems can automatically pick, inspect, and place parts based on any measured dimension.

At Comprehensive Logistics in Youngstown, Ohio, a UR10 cobot equipped with a Keyence CA-HX200 C Lumitrax vision system is deployed on the fast-paced engine assembly line, checking the correct assembly of the plug-ins for the steering gear wire harness. The task is mission critical. If there is an intermittent connection caused by a connector not fully seated and locked into place, it can cause a loss of the power steering, which is a level 8 on the severity scale—meaning a life-threatening failure mode.

Manufacturers are also turning to cobot platforms that offer customizable vision systems in an effort to inexpensively future-proof their operations in an era of uncertainty for the manufacturing sector. At the same time, these versatile automation platforms create opportunities for manufacturers: companies running flexible automation are better able to meet their customers’ current and future needs than a manufacturer operating within the limitations of traditional industrial robotics.

The future of quality inspection is one that will see quality professionals working side-by-side with collaborative robots fitted with easily-swapped vision systems; the robots will take care of the less glamorous side of the job from machine tending to pick & place, while humans focus on higher-level strategic thinking. V&S