Home » Keywords: » automation technologies

Items Tagged with 'automation technologies'

ARTICLES

Vision & Sensors | Trends

From the warehouse to the food production line, today’s high-speed imaging applications require more than just faster cameras.

Read More

Vision & Sensors | Automation

What is Trustworthy AI for Quality Control?

Quality control in manufacturing relies on automation – and people.

April 30, 2024

Automation

How Automation Can Help You Achieve Your Growth Targets

The work that employees enjoy least is generally the most suitable for automation.

April 22, 2024

Vision & Sensors | Trends

Trends in the Machine Vision Market

Observations on the market and the technologies that could be the next to impact applications in automation.

January 4, 2023

Quality 101

Automation: Should Manufacturers Fight Or Flight?

Despite its praised benefits, many manufacturers still decide against automation. But does that decision stem from fear?

August 16, 2022

NDT | Back 2 Basics

Robotic Computed Tomography Ready for NDE 4.0

Besides the automation of a CT system for NDE 4.0, it is very important to digitize the whole process for NDE.

August 8, 2022

Measurement

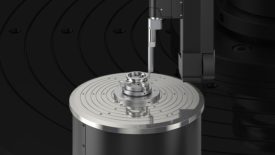

Roundness Measurement Technology Drives Quality and Productivity

For certain parts and products, roundness measurement is a critical part of the quality assurance process.

August 1, 2022

Vision & Sensors | Machine Vision 101

The Use Of Machine Vision For Robot Guidance Offers New Possibilities

Effective robot guidance requires specific machine vision sensors and techniques.

July 6, 2022

Vision & Sensors | Automation

Bringing AI to Visual Inspection

Adding automated decision-support for human operators helps speed visual inspection rates and improve product quality.

January 1, 2022

EVENTS

Webinar

4/18/24 to 4/18/25

Contact: Meg K.

Focus on What Matters: The Future of Digital Precision in Manufacturing

Webinar Sponsored Webinars Sponsored

8/22/24 to 8/22/25

Contact: Meg K.

Unleashing Quality Data: Driving Business Success With Advanced SPC Tools

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing