Jim Anderson

Jim Anderson is the digital business consultant for machine vision at SICK Inc. For more information, email [email protected] or visit www.sickusa.com.

ARTICLES

Vision & Sensors | Machine Vision 101

Effective robot guidance requires specific machine vision sensors and techniques.

Read More

Vision & Sensors | Robotics

The Rise of Smarter Robots

Using a high-quality 3D camera, the robot can locate the part, regardless of orientation, and provide pick coordinates to the robot.

March 1, 2022

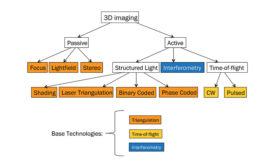

A Closer Look at 3D Imaging

Capturing the third dimension can be done in many different ways, and each of the machine vision technologies available has its pros and cons.

September 1, 2016

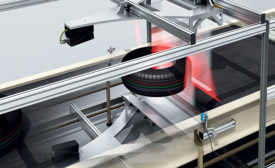

The High-Speed Trend

Automating Manufacturing Processes with High-speed 3D vision improves quality and drives down costs.

March 1, 2016

Select the Best Identification Technology

THE BASIC AIM IS TO DETERMINE WHAT LEVEL OF AUTOMATION NEEDS TO BE ACHIEVED.

March 3, 2015

A New Vision for Vision Guided Robotics

Growing acceptance changes manufacturing processes.

December 10, 2013

Vision & Sensors - Vision Technology

Code Quality

In-line vision-based technology reduces downtime.

July 9, 2013

Vision & Sensors - Cameras

Multiscan and CCD

Camera functionality continues to advance.

July 9, 2013

Vision & Sensors - Smart Cameras

Trends in Vision: Application-specific Integrated Solution Blocks Improve Quality

January 2, 2013

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing