Statistical sampling has been a very popular topic in recent years. The sampling strategy is an important part of statistical sampling. Manufacturing organizations find the following sampling strategies to be useful:

Click on each image to enlarge.

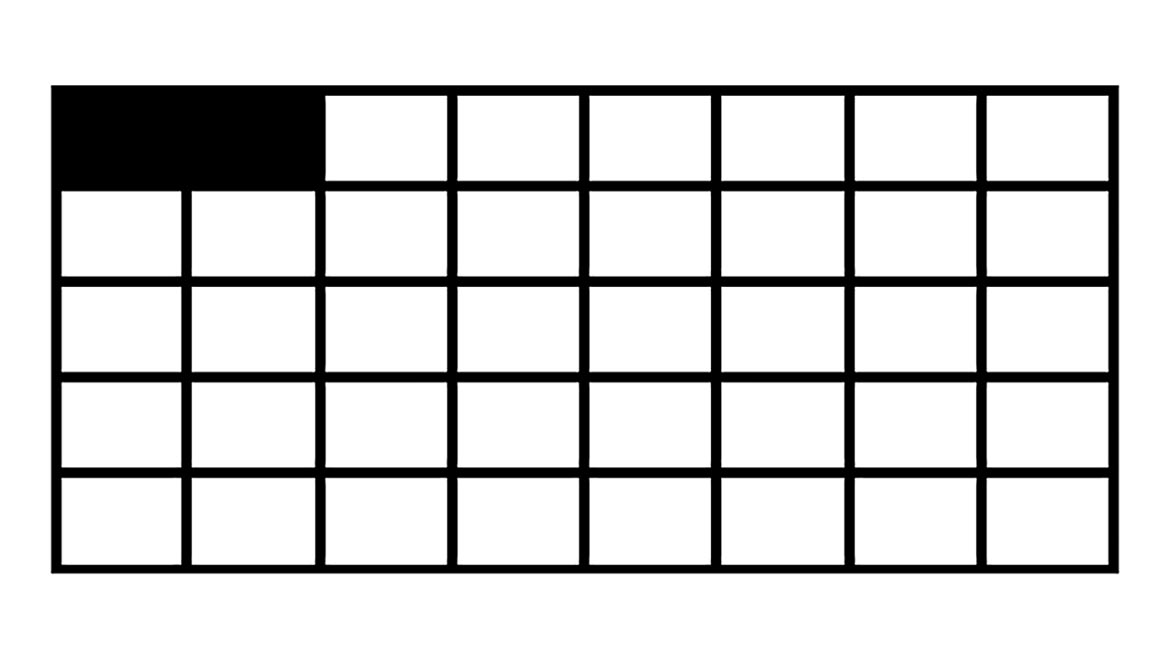

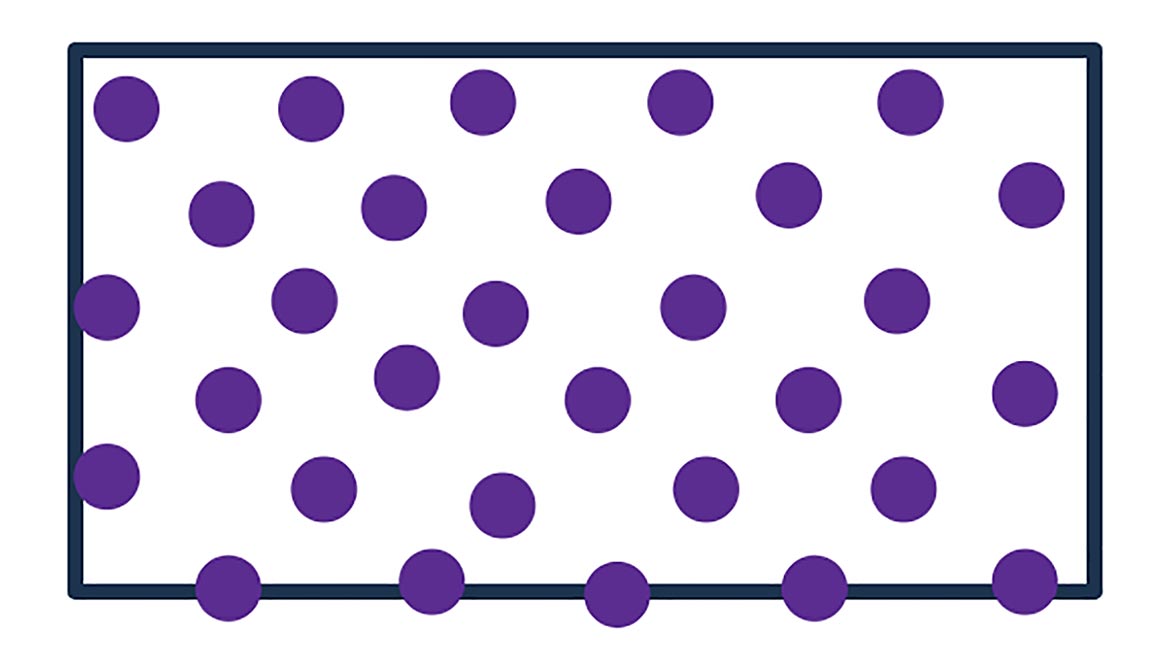

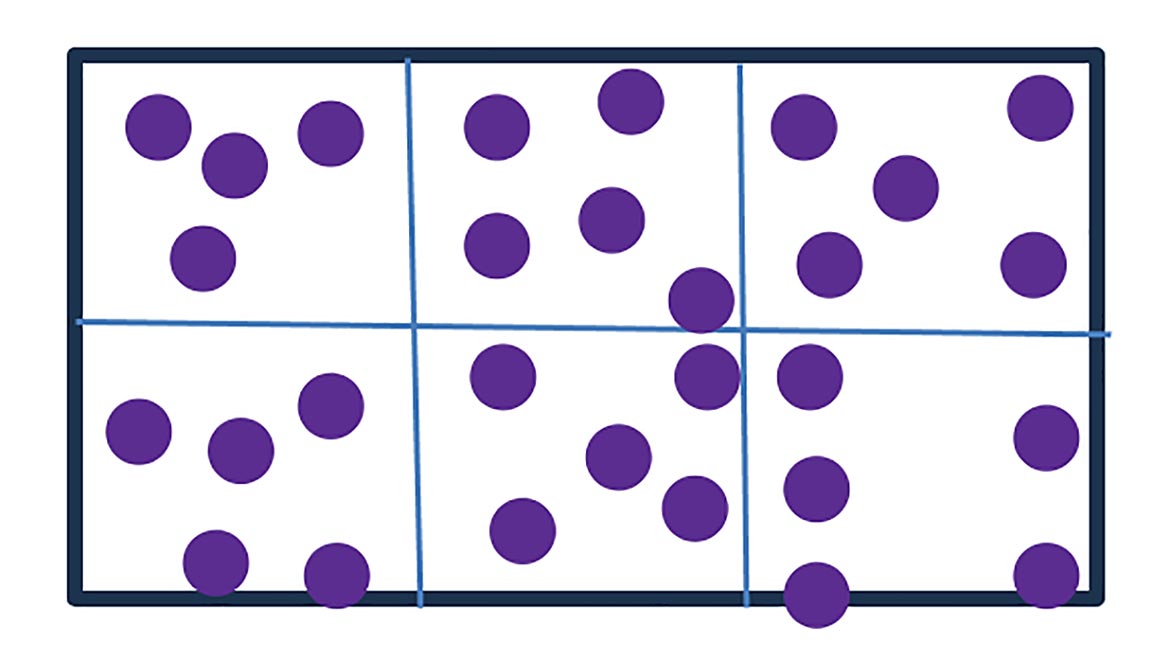

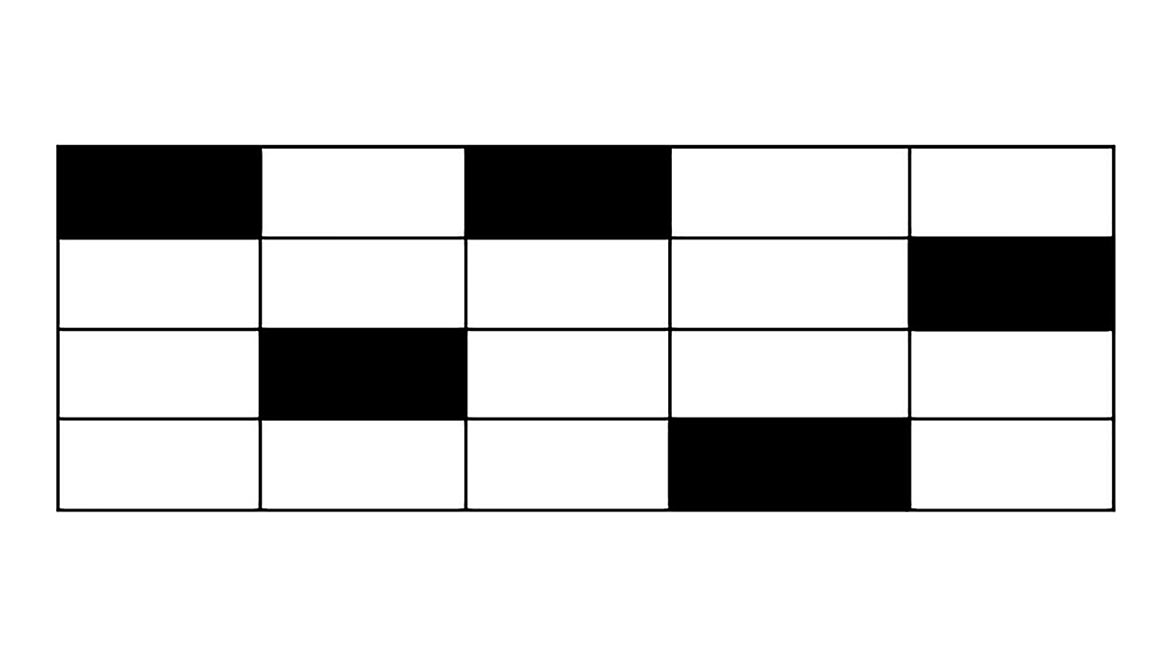

The examples illustrate the different sampling strategies for a two-dimensional population, such as products spread open for a drying process. There is no statistical guidance on which sampling strategy is superior to the others. ISO 2859-4 (1999) advises: “The items selected for the sample shall be drawn from the lot by simple random sampling …. However, when the lot consists of sub-lots or strata, identified by some rational criterion, stratified sampling shall be used in such way that the size of the subsample from each sublot or stratum is proportional to the size of that sublot or stratum”.