Home » Computed Tomography (CT)

Articles Tagged with ''Computed Tomography (CT)''

Reverse Engineering Continues to Expand its Role in Industry

Reverse engineering parts and systems enable aircraft to keep flying or machines to keep running.

October 1, 2016

Certified Inspection with CT Scanning

The most accurate CT scanning systems are built like a CMM with an X-ray probe.

July 1, 2016

Measurement

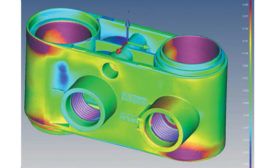

Seeing is Believing: X-ray Computed Tomography for Quality Control

Industrial X-ray CT is a 3-D measurement technique with many advantages.

June 1, 2016

INDUSTRY HEADLINE

Exact Metrology Holds Tech Expo With 3DVision Technologies On 3-D Scanning & 3-D Printing

April 8, 2016

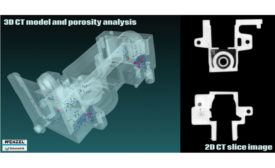

Manufacturing Issues and Measurement Techniques for Assessment of the Effects on Structural Performance of Composite Parts

Computed tomography (CT) offers accurate three-dimensional measurement and characterization of defects in composite structures.

November 9, 2015

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing