Roger Zeoli

Roger Zeoli is manager of bench & machine gages at Marposs Corp. (Auburn Hills, MI). For more information, call (248) 370-0404, email [email protected] or visit www.marposs.com.

ARTICLES

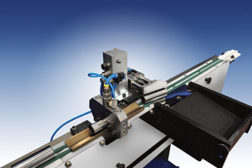

Flexibility is the Name of the Game in Shaft Gaging

Today you have a lot of choices in terms of hardware, software and gaging technology.

March 1, 2017

Measurement

In-Line Gaging Systems Can Impact More Than Just Part Quality

Learn more about the world of in-line gaging.

January 3, 2013

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing