Pick up any shaft or threaded fastener. How are you going to check it? An outside micrometer is most often the go-to tool for measuring diameters. A height gage or drop indicator could be used to check dimensions between part features, while an optical comparator is a good way to inspect thread forms or measure a groove width. And runout from one diameter to the next is easily measured with a V-block and test indicator.

These are just a few of the inspection methods used by shops everywhere, every day, to inspect machined parts. All are relatively simple to perform, require little investment or training, and no quality engineer would argue with their validity. There’s just one problem: they’re slow. What’s the sense in taking ten or fifteen minutes to measure a part that needed but a fraction of that time to produce? Further, what about the documentation and subsequent archiving of inspection results? In a paperless world, old-fashioned metrology comes up short.

The ROI on AOI

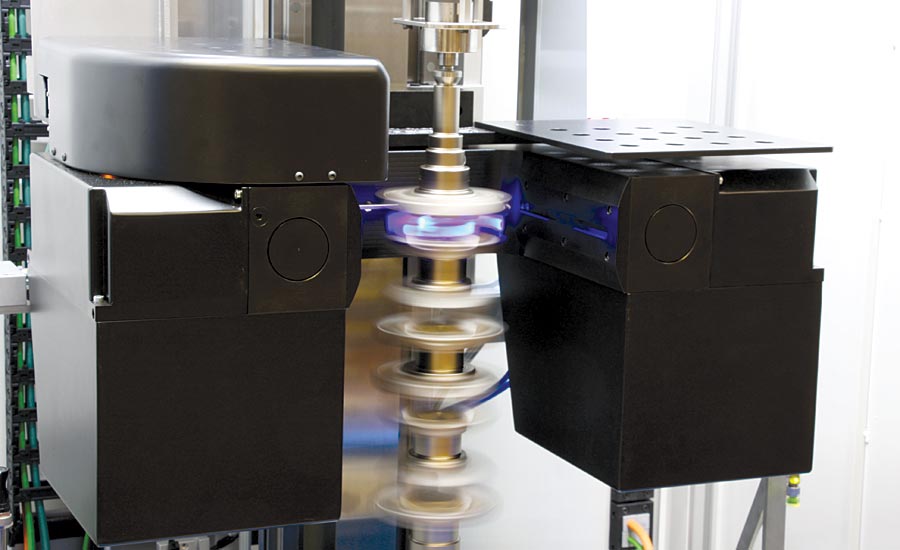

This is where automated optical inspection (AOI) comes in. With AOI, parts are measured in seconds, not minutes. There’s no fussing with gage blocks or micrometers, no need for aligning parts on crosshairs. AOI means setting a part on a stage, in a fixture, or between centers, and pushing a button. Anything within view of the system’s camera or image sensors is instantly measured—multiple times, in some cases—and the results collated by a computer. The cost of quality is reduced; measurement throughput greatly increased. Best of all, there’s no more backlog in the inspection room.

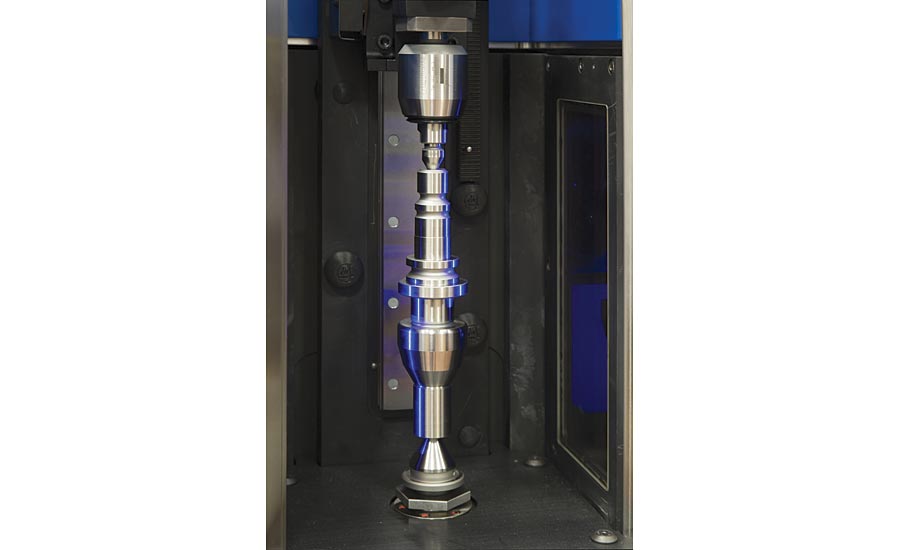

But how does AOI work? Simply put, optical inspection systems use a high-resolution camera to capture an image of a workpiece—a profile of a shaft or other round workpiece, for example, surface features such as a machined slot or bolt-hole circle on an orthogonal part, or even milled pockets, mold cavities, and three-dimensional swept surfaces.

In fact, a quick glance or two from an optical inspection system provides highly accurate measurements of these or virtually any other part feature, without the need for expensive hard gaging and lengthy inspection procedures. Between AOI and its probe-based cousin, the CMM, there’s little that can’t be measured. Unlike most coordinate measuring machines, however, AOI is an excellent addition to most factory floors. There are no fragile probes to worry about, far fewer moving parts, and operation is about as difficult as snapping a photo with a smart phone.

Here, there, and everywhere

If you’re concerned about the welding smoke, grinding dust, and machine tool cutting fluid mist floating about the factory, and wonder how these microscopic particles might interfere with the cameras and sensors in an AOI, don’t be. As long as the workpieces are clean and the air is safe for humans, optical inspection is perfectly suitable for shop floor use.

This makes AOI the switch hitter of the inspection world. An optical system can be used in a standards laboratory, for instance, just as readily as it can a production environment. What’s more, a single measuring device supports any number of machined parts, be they milled, turned, ground, or EDM-ed, provided they fit within the work envelope.

Consider an automotive transmission plant, where a variety of shafts are produced, each at a different stage of the manufacturing process. In this scenario, a single optical machine can be used to measure and document most everything on the production floor, and is easy enough that anyone can step up and use it with little training. This level of convenience and ease-of-use means operators will be more likely to inspect their workpieces, more frequently, without wasting time walking to the inspection lab.

An optical system can be used in a standards laboratory just as readily as a production environment.

This is why automotive, aerospace, medical, and indeed manufacturers of all kinds use AOI to measure a range of machined parts, from camshafts and threaded fasteners to hydraulic pistons and electrical components. Such systems are very flexible, and can address the needs of customers in many different industries and segments.

Measurements in a flash

Here are a few recommendations for anyone currently kicking the tires on an AOI system:

- A measurement system should be easy to use, with an intuitive software interface and a library of standard part features.

- Dimensional, position, and form measurements should be available in both static (non-rotating) and dynamic modes.

- For shops that make threads (which is most of them), the ability to check form, pitch, root, and major diameters is a big timesaver.

- In general, systems with multiple sensors provide greater accuracy, and above all, measurement speed. Flexible lighting options should also be available.

- With Industry 4.0 and the ever-increasing need for integration, a modern AOI should have plenty of options for connecting to machine tools, printers, external devices, and corporate networks.

- Look for a system with the ability to easily import and export DXF files and other CAD formats, which simplifies programming.

- Automatic archiving of measurement results together with “smart” search capabilities supports trend visualization and traceability.

Optical inspection systems use a high-resolution camera to capture an image of a workpiece.

The bottom line is this: in the past, manufacturers relied on dedicated gaging to measure their products, but just as the industry is moving forward with more flexible manufacturing systems, there’s a need for more flexible gaging to accompany this trend. Optical measuring systems allow you to inspect a wide array of parts with a single device, simplifying the measurement process while reducing costs.

It’s also extremely capable. You can acquire an image of any shape within milliseconds, and assuming the software has the correct algorithms, can process it in a variety of ways. Tiny details like small radii or grooves are quite easy to measure, something not normally possible with traditional contact solutions; in these and many other cases, only optical measurement can do the job. And when you combine this capability with contact measurement, flexibility is increased even further. If you haven’t yet checked out optical inspection systems, do yourself a favor and take a look. Q