When I was asked to write this article it took me back to reactions I received after it became known that I was the whistleblower who turned in Ultrasonic Research and Testing Laboratory in 1991.

Some of the NDT community’s reaction to my blowing the whistle on the fraudulent activity at URT in Dallas, Texas, totally caught me by surprise. I knew that the Lab’s owner and the NDT Level 3 / QA Manager had many friends in the industry. Most people involved in the NDT profession understand what I am talking about. The nondestructive testing (NDT) industry is a close-knit group. Sometimes it seems that everybody knows everybody.

An Aerospace Whistleblower Shares His Story

Dale Norwood of Norwood NDT Consulting describes how he blew the whistle on an NDT company in the 1990s after seeing falsified inspections.

Dale Norwood of Norwood NDT Consulting describes how he blew the whistle on an NDT company in the 1990s after seeing falsified inspections.

Listen to more Quality podcasts.

What I found most disturbing was the amount of support that those individuals who had committed the fraud seemed to have in the industry. Multiple times, NDT Level 3s questioned my actions. As an example, a few of the comments made to me were “Why would you do that to my friend?” “Why did you turn in URT? Everyone does it.”, “Why didn’t you just quit?”and the comment that surprised me the most was “You know 98% of all the falsified parts would have passed inspection anyway.”

It appeared that they assumed the lab was only falsifying a handful of parts per year and did not realize that the number of inspections falsified was anywhere from 100K to 200k per year. And many of the falsified inspections were on fracture critical components. It seemed that they were of the opinion that it was normal to expect some amount of falsification to take place.

During the sentencing hearing of Ultrasonic Research and Testing Laboratories at the Federal Courthouse in Ft. Worth, Texas on March 12th, 1993, Federal Judge Eldon Mahon made the following comment. “Mankind is greedy, selfish. We have to have rules and regulations. We have to be controlled. All of us have to be controlled. I don’t care whether it’s lawyers or doctors or teachers or whatever. There has to be some kind of control put on us. If there’s a dollar in it, we’ll take advantage of it. Now that’s a bad commentary on our society, but that’s what happened to this nation.’’

Sadly over 30 years later his statement still rings true, maybe even more so today. During the past few years, the NDT Industry has had its share of ethical issues. Don’t get me wrong. NDT is a great profession. I am proud to have called NDT my occupation for well over 40 years. I truly believe that the majority of certified inspectors are highly ethical and try to perform their job to the best of their ability. But just as Judge Mahon alluded to 30 years ago, it doesn’t matter the occupation, if there is a dollar to be made someone will find a way to break the rules.

NDT

Related Article

It has been my observation that if an individual, on his own, has made the decision to falsify inspections it can be very hard to detect. If the falsification is brought to light, it can be extremely bad for the individual and in many cases, for the company he works for.

Why would an inspector falsify inspections on his own without being told, or ordered to? In many cases the individual is not benefiting monetarily, but simply want to look good or just do not care anymore. There are many reasons, and some might surprise you. On many occasions inspectors want to impress management by showing how much product they can inspect. Others simply stop caring or assume it’s not that big of a deal. Even in my case, on one occasion while working as a Level 2 UT inspector at Ultrasonic Research the NDT Level 3 accepted a weld on a pressure vessel that I had previously rejected due to lack of penetration on 100% of the weld. When questioned if he agreed with me that the weld was rejectable he stated “Yes,” but then went on to comment “I just don’t think it’s that big of a deal!”

There are many examples of NDT inspectors being caught falsifying inspections and of the punishment they received. One case involved an ultrasonic inspector assigned to inspect welds on Navy vessels. In 2007 a Virginia man plead guilty to falsifying the inspections on over 9,000 welds he certified on submarines. In his plea deal he was sentenced to 37 months in prison and required to pay the U.S. government $654,000. What was the reason he gave the court for his actions? During his sentencing he stated his reasons as “Just being lazy or the pressure I placed on myself to get the job done” and “I began to care less and less.”

There are many other stories of NDT inspectors falsifying x-ray reader sheets, mis-labeling x-ray film, falsifying inspection reports and forging other inspector’s names to certification reports. The list goes on and on. In many cases, those found guilty end up with a prison sentence and a substantial fine. That’s a hard lesson to learn for simply not doing the job you are paid to do.

As I mentioned earlier, it is not limited to the NDT industry. In one of the more shocking stories, in 2014 a hospital technician was sentenced to six months in prison for manipulating the mammogram records of 1,289 patients. She told the patients their mammograms yielded negative results, when in fact a doctor had never reviewed them.

Even the legal profession is not immune from fraudulent activity. Years ago, I hired an attorney to handle a speeding ticket and later saw him on the local news being arrested one night for falsifying his law license.

Despite all the cases I have discovered, I don’t believe that any of the cases of NDT fraud come close to the amount of falsification being committed at the Dallas, Texas NDT lab. Court documents reveal that the damage and loss to the aerospace industry during a 3.5-year period from 1988 to 1991 is almost incalculable. I was told at the time that damages could exceed $200 million, and if you figure in the previous years, the damage would be almost immeasurable. In the case of Ultrasonic Research and Testing Laboratory, it was a monetary benefit to the owners of the lab. The owner of the testing lab did not personally plead guilty but plead guilty for the corporation in stating that he turned a blind eye to the falsifications that were being committed in his inspection lab. I have no idea if the QA Manager / NDT Level 3 committing the fraud benefited or not, and he claimed he acted on his own. He did admit in court documents to falsifying 90% of all parts entering the lab for ultrasonic testing, and he was the only person given a prison sentence for his actions. Shockingly, after his release from prison he had no problem finding work as an ultrasonic inspector for multiple companies.

Although the NDT industry is always attempting to find ways to detect fraudulent activity, I am not sure if it is possible to stop it from happening. In my opinion, the best way to deter inspectors from falsifying inspections would be to show inspectors examples of court cases where the inspectors committing the fraud were given prison sentences and large fines.

Some aerospace companies are now requiring their suppliers to have the newly certified NDT inspectors sign ethics forms as part of their certifications. I seriously have no idea why anyone would think that signing a form would deter an individual from falsifying inspections. If an individual has made a decision to commit fraud, it is highly doubtful the fact that he signed an ethics form is going to stop him.

Another solution developed recently to help detect fraudulent activity is through Defect Rate Monitoring. This requirement is now being flowed down to NDT suppliers through the Nadcap (National Aerospace & Defense Contractors Accreditation Program) Checklist and from some OEMs. Depending on the Defect Rate Monitoring method chosen to use, the company will monitor the failure rates of specific parts for individual inspectors over a specified time period. As an example, the failure rate of all Level 2 Radiographers interpreting the images for a specific part number, or material type, will be monitored. When reviewing the data if the average failure rate for a specific part is, for example, 20%, but one of your inspectors rejects the same part at an average of 2% failure rate, you would simply have your NDT Level 3 review his x-ray images to determine why the low failure rate. Is this a perfect system to detect fraudulent activity? No. But there have been cases in the past where it has been determined that an x-ray inspector acted on his own to falsify inspections, and when the inspection records were reviewed it was found that the inspectors failure rate was 0%. This could have been detected earlier if Defect Rate Monitoring had been in place.

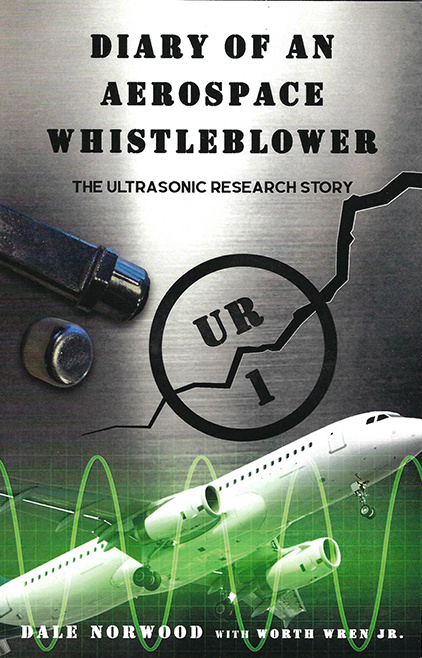

Since the release of my book, “Diary of an Aerospace Whistleblower,”I have had the opportunity to speak to employees of aerospace companies and students attending college NDT programs many times about my first-hand experience, including discussions on the current state of NDT. What I have found most eye opening are the open discussions after my presentations. It never fails that multiple individuals, either in the group setting or one on one with me after my presentation, will relay stories of fraud that they have witnessed, or describe how they were asked by customers to provide acceptable NDT inspection reports for cash or gifts.

At the conclusion of my book I asked the question “Does the NDT Industry still have an ethics issue?”

Sadly, from the discussions I have had, the answer appears to be YES.