Articles by Ken Myers

Manufacturers must take the opportunity now to bolster their quality systems.

Read More

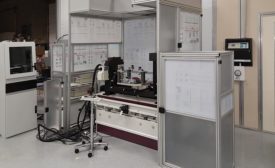

Automated Metrology: Manufacturing Trend of the Future

Most manufacturers looking to automate metrology are in search of a better way to handle inspection tasks and, in turn, be more efficient and profitable.

December 1, 2019

Robot, Robots, Everywhere!

Robots are the go-to tool for manufacturers wanting to increase throughput along with quality and efficiency.

April 1, 2019

Faster, High Tech Machines Demand Enhanced Safety Precautions

Operators, engineers, programmers and maintenance personnel should adhere to any and all safeguarding procedures put in place.

November 1, 2018

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing