Fabtech showcased new 3D printing technology as well as quality tools. In the smart manufacturing hub, companies such as Microsoft, Stratasys, SLM Solutions, Desktop Metal and Memex made the case for data-driven manufacturing and described how companies can get there. As Microsoft said, “AI is ready. Are you?”

Many described the business case for additive manufacturing, and said it is still getting started. Or, as Desktop Metal said, “Today’s metal 3D printers are like 1970s punchcard computers.”

SLM Solutions described parts that can take 45 hours to print, saying, “Materials are irrelevant if the quality isn’t there.” If something goes wrong in the 44th hour, that can be an extremely costly mistake. Meanwhile, the GE turbine engine seemed to be the poster child for additive manufacturing. Several presentations described how the company was able to redesign an engine from hundreds of parts to just 12. According to GE, “A dozen 3D-printed parts replaced 855 components produced by multiple contractors.”

Next year Chicago will host FABTECH November 11-14. More than 50,000 attendees and over 1,700 exhibiting companies are expected.

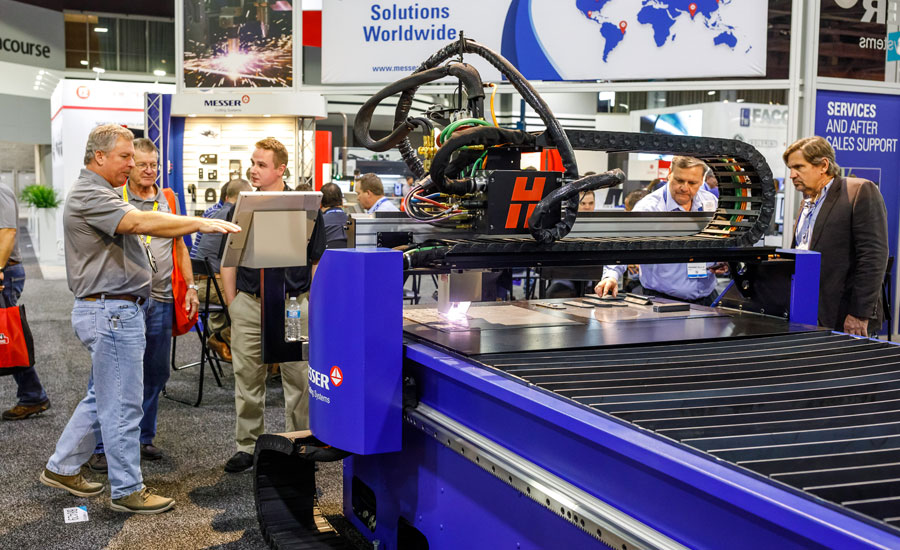

Photo source: FABTECH

Photo source: FABTECH

Photo source: FABTECH

Photo source: FABTECH

Recent Comments

Therefore great deal to take place over kinds...

Gee… I translate writes on a similar to...

As it turned out, it is quite possible...

For some it is significant, and so research...

nike tiffany and co jacket