Home » Keywords: » CMM

Items Tagged with 'CMM'

ARTICLES

Management

A Machine Trainer: Safe and efficient shop floor training management

Learn more about CNC and CMM machine trainer simulators.

October 23, 2023

Measurement

Why More Manufacturers Should Consider Implementing a Vision Measurement System

Technology advancements, emerging industries, and congressional legislation point to an exciting future for vision measurement systems.

October 18, 2023

Software & Analysis

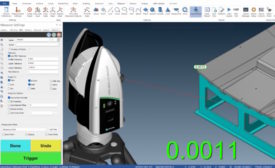

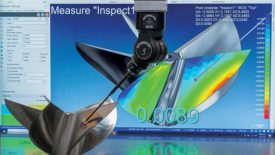

Choosing the Right Measurement and Inspection Software

January 5, 2023

Why model-based Measurement Helps Manufacturers Improve Quality

Improvements in CMM equipment and developments in model-based software solutions have also helped make the technology more accessible.

March 23, 2022

Quality 101

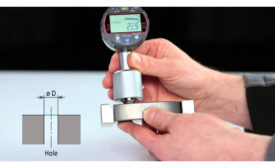

5 Things To Consider When Evaluating Shop-floor CMMs

As your manufacturing processes change over time, you need your quality program to keep up.

March 8, 2022

EVENTS

Webinar

9/13/23 to 9/13/24

Contact: Meg M.

How to Reduce First Article Inspection Creation Time by 70-90%

Webinar

3/14/24 to 3/14/25

Contact: Meg K.

The Ride to Excellence: Embracing Digital Twins in Automotive Design, Development & Production

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing