This article can be helpful to anyone tasked with selecting software, however, it is written from the perspective of realizing effective measurement and inspection solutions for manufacturing enterprises.

Too often manufacturing companies either minimize the importance of measurement and inspection software or worse, they make purchase decisions based on hardware features that may or may not provide the results they need. It is only after they take delivery and use the equipment do they realize they have purchased software that is not up to the task, or the wrong type of CMM given their workflow and the results they require.

The following process steps are intended to illustrate a comprehensive approach to software selection, with critical consideration given to subjects like needs assessment, compatibility, and extensibility. Following this process, you will gain a clear perspective of your needs and a better understanding of key questions to ask and features you should insist upon. The result will be a grounded solution that provides results, enhanced workflow, and added value across your manufacturing enterprise.

Needs Assessment

You have probably heard it said, “If you don’t know where you are going, any road will take you there.” Well, this holds true for selecting the right measurement and inspection software for your business as well. Before purchasing any software, regardless of application, you need a clear assessment. What problem or opportunity are you addressing with technology? How are you getting the data you need, today? What is your workflow? What benefits will be expected from your new software? And most importantly, who else in the organization will be affected?

Specific to measurement and inspection, there are a few considerations that surprisingly are often overlooked. These include identifying the maximum part volume to be measured, understanding the number of measurement points needed to calculate results, and the speed required to complete the process. Failure to consider these points may lead to a solution that is inefficient or worse, one that does not support critical workflow.

What you do not want to do is see an impressive CMM and buy it based on a demo, possibly unrelated to your workflow or measurement objectives, then try to figure out why it is the best solution for your organization. That is putting the cart before the horse.

Communications

Clear communications should start with your assessment and carry through the balance of your technology acquisition and implementation. You would be surprised how many people in your organization can be positively impacted by data gleaned from measurement and inspection software. Once you have made the investment, the application tools can be used for quality inspection, reverse engineering of existing parts or recreating data for missing features, support for tool making, and guided assembly of components, fixtures, and weldments. Collected data can feed downstream applications like product lifecycle management (PLM), and statistical process control (SPC) databases. Understanding whom these stakeholders are and keeping them in the loop creates a great deal of added value to your software investment.

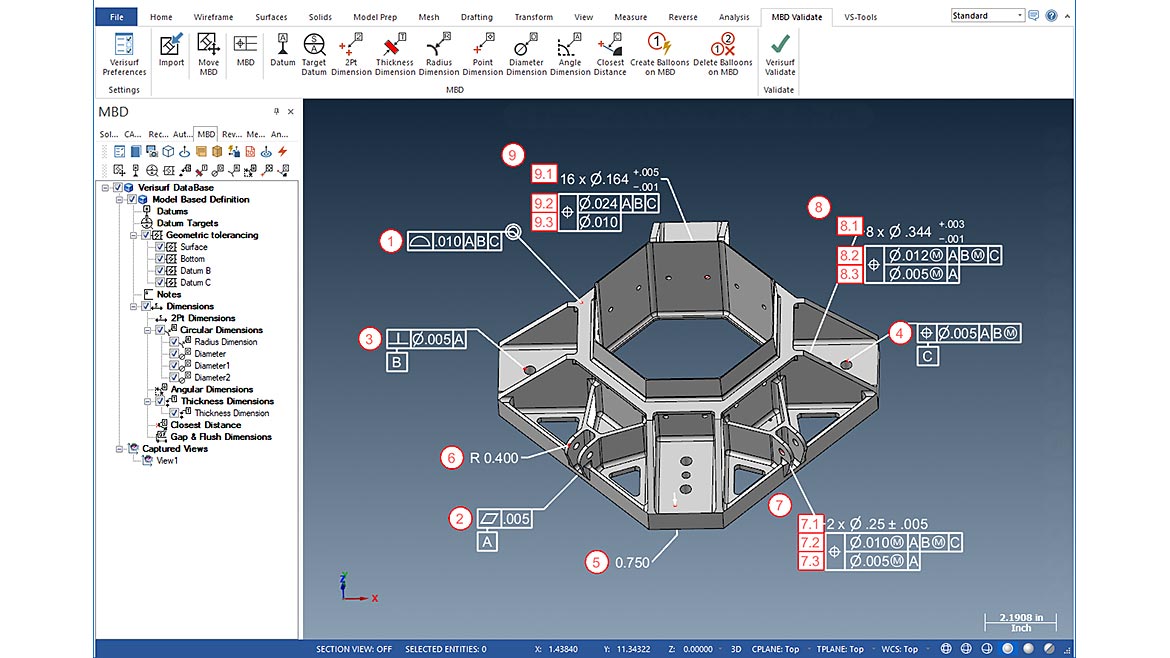

When selecting measurement and inspection software make sure that it not only is compatible with CAD but is CAD-based at its core. A good question to ask is, “Does this software include intelligent 3D CAD modeling capabilities?” | Image Source: Verisurf Software

CAD Connection

In today’s business environment, every software platform must play well in the sandbox with already-established enterprise software or protocols. For business intelligence this may be ERP software, for business communications, it might be Microsoft. Within the manufacturing enterprise, the standard is CAD. Finished products and components are typically conceived in a CAD environment and for most manufacturers, they remain in this virtual state throughout the design-build process. Data continues to be added to the file and its digital references, quite often, throughout the lifespan of the product.

Model-Based Definition (MBD) is the term given to this commitment to an intelligent CAD model. The central concept embodied in MBD is that the 3D model provides all the detailed product information necessary for all aspects of the product life cycle. In the example of a machined component, this would include intelligent Geometric Dimensioning and Tolerancing (GD&T) annotations. This removes ambiguity, conflict, and doubt that arise when drawings and models co-exist. With authority bestowed on the model, MBD eliminates errors that result from referencing an incorrect source and makes processes more efficient—no more searching to determine correct revision levels.

When selecting measurement and inspection software make sure that it not only is compatible with CAD but is CAD-based at its core. A good question to ask is, “Does this software include intelligent 3D CAD modeling capabilities?” A truly CAD-based platform is the best way to ensure data continuity (digital thread) and maximize model-based measurement and inspection applications across your manufacturing enterprise. Even if your organization is not at the point of fully embracing MBD, you want software extensibility and room to grow.

Software Compatibility

If you make CAD-based measurement and inspection a requirement and do your homework, you will be halfway to nirvana with respect to compatibility. The CAD connection will allow you to import, edit, save, and export to and from virtually any CAD software. This is important when it comes to creating inspection plans that might have missing GD&T data that needs to be added, or when using reverse engineering to fill in missing features. Having an open CAD platform from which to operate and manage your measurement and inspection applications makes downstream integration and data sharing much easier using common file types and established transfer protocols.

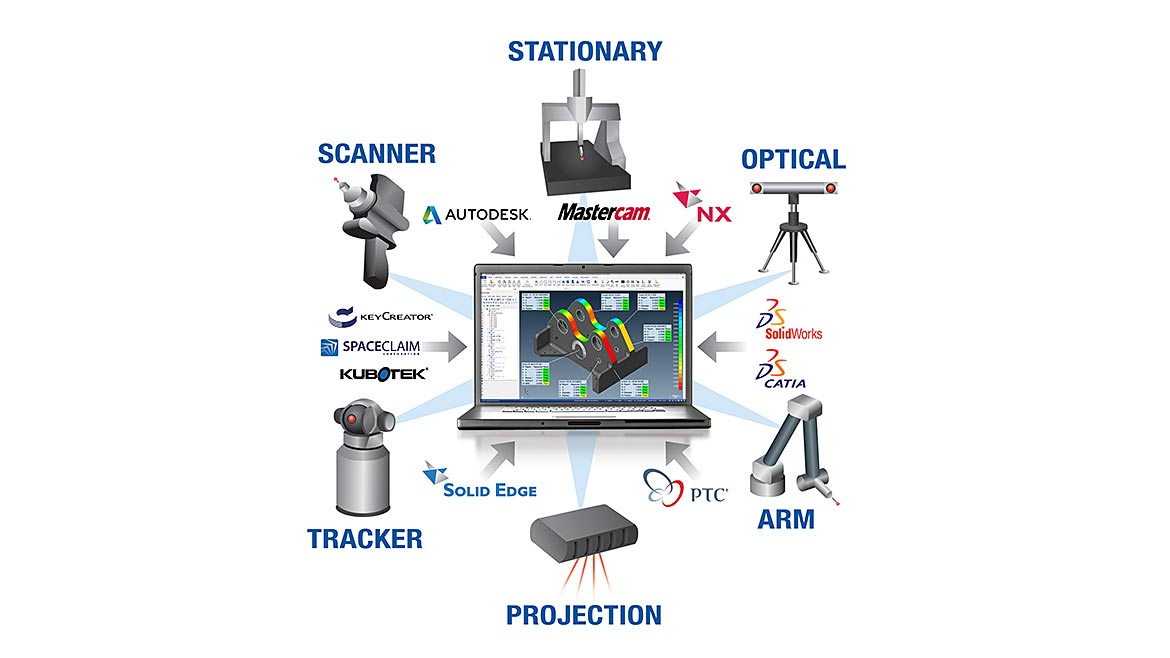

When evaluating measurement and inspection software, universal compatibility with all CAD software and all new and legacy hardware is essential for data continuity, repeatable process control, and optimum resource utilization. | Image Source: Verisurf Software

Hardware Compatibility

There are many types and brands of CMMs available on the market and if you remove the software from the equation, they all do one thing very well, they collect precision measurement points, period. The power behind all CMMs, including contact or noncontact, fixed or CNC type, portable arms, trackers, and more, is the applications and workflow provided by the supporting software. Most all CMMs come with some sort of measurement and inspection software, but one could argue that the competency of many CMM manufacturers is in precision measurement and specifically motion control, and not software development. CMM manufacturers also tend to be product-centric when it comes to software, focusing only on their machines. It is for this reason that you need to keep your evaluation of software and hardware separate and stay true to your assessment plan. Consider your workflow and corresponding software applications first. This will lead you to the correct type of CMM you need, and then you can decide on what brand of CMM.

Now, when looking at measurement and inspection software from a hardware compatibility standpoint, it is important that the software can drive all CMMs and import measurement points in real-time. This is especially important when collecting and processing very large measurement sets encompassing millions of measurement points, typically associated with noncontact scanning of large complex surface profiles. The software must be able to keep up with the influx of data, otherwise, your productivity will grind to a crawl.

Universal device compatibility is critical when it comes to measurement and inspection solutions for the manufacturing enterprise. In the case of inspection, workflow routines should be able to be programmed once and then executed using any available CMM. This provides flexibility and consistency among operators and ensures repeatable process control is maintained, which is a key tenant to quality management.

Integration

Selecting a measurement and inspection software that is based on an open platform, with compatibility and interoperability built-in, is critical to advancing the concept of the digital thread. To be effective, each step of the design/build process must do its part to stay connected. Data in, data out, and the ability to pass information across all manufacturing applications and databases. A good question that will confirm a software’s commitment to interoperability is, “Do you offer a Software Development Kit (SDK)?” If the answer is no, integration might be harder than you think.

Training And Maintenance

Training and compatibility go together. Over the last 10 years, there has been a surge by shops to add portable measurement and inspection assets. These newer devices are based on open software compatibility, but many of the legacy CMMs that are still in use are based on closed systems and require dedicated software to run them. This has created a dichotomy in some shops between new and legacy systems. Certain quality inspectors are trained to operate legacy machines and others are versed in newer equipment. This causes bottlenecks due to inefficient resource utilization.

Your software selection should be enterprise-based. One software to drive all your CMMs (regardless of type or age), manage workflow, and provide desired application results. This will help with resource utilization, reduce bottlenecks, and lower software training and maintenance costs by not having to support more than one platform.

Ask For Help

When it comes to selecting inspection and measurement software, getting it right is important. Do not be hesitant in asking for help. Software and hardware providers alike should be willing to take an interest in your business and help you put together the right recommendation for your unique application. But try to remain objective and stick to your goals. There are many measurement and inspection solutions available. Hold out for the one that fits your needs.