Home » Keywords: » coordinate measurement machine (CMM)

Items Tagged with 'coordinate measurement machine (CMM)'

ARTICLES

CMS Column | Justin Novak

A lot has happened since 1984, and we're just getting started.

Read More

Measurement

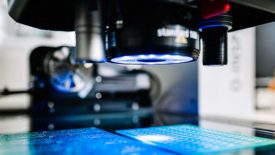

Metrology and Microscopy for Electronics Quality Assurance — in One Machine?

Compliance can often only be achieved through both metrology and microscopy tools.

March 5, 2024

Quality Headline

Fowler High Precision Appointed Exclusive U.S. Distributor for Aberlink’s Shop Floor, Lab Grade CMM Equipment

March 4, 2024

Case Study

Unlocking Efficiency in Education

Inspection Arsenal fixturing transforms student part inspection at Van Buren Tech in Lawrence, MI.

March 1, 2024

Sponsored Content

Kindig-It Design, Can Dig It Thanks to FARO 3D Measurement Solutions

Premium Custom Car Restoration Leader

February 26, 2024

Sponsored Content

A Beginner’s Guide to Contact Measurement and 3D Scanning

February 26, 2024

Quality 101

The Next Dimension of Precision: Integrating Rotary Tables into Coordinate Measuring Systems

The accuracy and reliability of CMMs and PCMMs are foundational to quality.

February 16, 2024

Test & Inspection

When Part Gaging is a Bottleneck

Automatic manual gauging improves process control, yield, and capacity.

January 26, 2024

Measurement

Multisensor Metrology Systems: Quality’s Swiss Army Knife

Always have the right tool for the job.

December 18, 2023

Case Study

Hitchiner Manufacturing Overcomes Casting Challenges with Automated Blue Light 3D Scanning Technology

By implementing automation, Hitchiner increased repeatability and speed.

November 30, 2023

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing