Home » Keywords: » manufacturer

Items Tagged with 'manufacturer'

ARTICLES

Software

Digging Deeper with Root Causes

It is helpful to extend your root cause analysis by looking at the problem from several different angles.

May 24, 2024

Management

The Essential Benefits of ISO Standards for Manufacturers

By implementing these standards, manufacturers can manage risks, drive continuous improvement, and gain a competitive edge.

August 25, 2023

From Good to Great: Why Manufacturers Must Monitor Their Continuous Improvement Processes

The Benefits of Tracking Progress and Adapting to Change in a Competitive Marketplace

April 3, 2023

Measurement

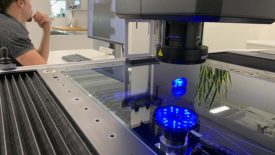

How to Measure the Intricate Components of Electrical Connectors

Quality assurance is critical for manufacturing electrical connectors.

March 30, 2023

NDT | Radiography

Why Additional Training Is Needed When Transitioning From Film Radiography To Digital Radiography

It is essential to have additional formal training to understand key image quality requirements.

February 14, 2023

Why Your Team Needs Statistical e-Learning Options

Six Sigma relies on statistics at its core. But using Six Sigma throughout an organization is not always straightforward.

December 9, 2022

EVENTS

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing