Home » Keywords: » software programs

Items Tagged with 'software programs'

ARTICLES

Software

Transferring microscopy applications into production often requires validation activities.

Read More

Software & Analysis

A Corporate Commitment to Quality Requires a Digital-First Approach

Four Trends Shaping the Next Gen in Quality Management

June 10, 2021

Low-Code to No-Code: A Software Development Revolution

When software can almost write itself, then it's future proof.

May 5, 2021

A Calibration Software Solution

Integrating calibration software with asset management software for a comprehensive calibration solution and work order automation.

June 8, 2019

What Chief Quality Officers Should be Concerned About in 2019

Quality opportunities are everywhere.

April 8, 2019

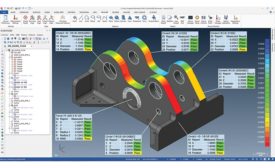

GD&T, Manufacturing Imperative

Without it, nothing ships, and nobody gets paid.

March 8, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing