Home » Keywords: » root cause analysis

Items Tagged with 'root cause analysis'

ARTICLES

Software

It is helpful to extend your root cause analysis by looking at the problem from several different angles.

Read More

Software

Finding Root Causes: How to Identify and Understand the Core Issues

Well, before you can find it, you have to know what it looks like.

May 23, 2024

Trends

Shifting Left in Manufacturing Quality

The future of quality in manufacturing is predictive.

January 16, 2024

From the Editor | Darryl Seland

Consolidation: One-Stop-Shops and All-in-One Computers

June 15, 2022

Test & Inspection

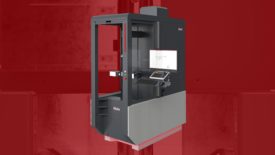

Is it Possible to Measure Shaft, Form and Gear with an All-In-One Machine?

Do more with less — minimizing downtime for production workpiece measurements.

May 30, 2022

Software & Analysis

Sledgehammer vs. Nutcracker: Which is the Right Tool for the Job?

Tools for identifying a problem, its root cause and its impact.

May 30, 2022

A Paradigm Shift in Internal Audits

How the power of teamwork strengthens the internal audit process.

March 15, 2020

Problem-Solving Basics

Use the following thoughts to avoid the damaging blame game.

April 9, 2018

EVENTS

Webinar

6/5/24 to 6/5/25

Contact: Meg K.

Mastering CAPA Writing: Enhancing Failure Investigation & Root Cause Analysis Techniques

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing