Home » Keywords: » weld inspection

Items Tagged with 'weld inspection'

ARTICLES

A New Angle on Aerospace FSW Inspections

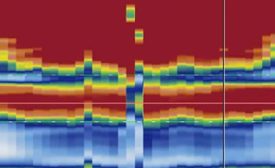

The most effective inspection method for friction stir weld flaws is phased array ultrasound.

July 1, 2020

Ultrasonic Techniques for High Temperature Hydrogen Attack

Well-trained NDT technicians using the right combination of ultrasonic techniques can improve plant reliability and worker safety.

June 8, 2019

Advertisement

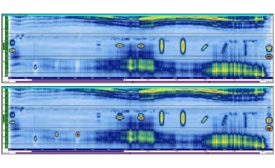

Weld Defect Imaging and Characterization Using PAUT and TFM Ultrasonic NDT

July 30, 2018

EVENTS

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing