Eddy current tester

The ED-400M eddy current test instrument detects cracks and near surface defects in steel and other ferrous metals. Once the probe is electronically balanced, the operator slides the probe over the inspection piece, keeping an eye on the easy-to-read meter. The meter needle then deflects, pinpointing the location of the flaw. Audio and visual alarms also can be set to alert the operator. The self-contained electronic instrument requires no adjustment when inspecting for defects through surface rust, oxides, paint or other coatings. The unit measures 5 inches by 9 inches by 6 inches and weighs 5.3 pounds. Re-chargeable nickel-cadmium batteries provide up to 50 hours of continuous operation on a single charge.Centurion NDT

(630) 736-5500

www.centurionndt.com

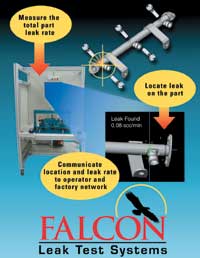

Leak testing

The Falcon Leak Test System simultaneously determines leak location and total leak rate, providing real-time process control. The system helps bridge the gap between traditional pressure decay technology and helium vacuum mass spectrometry. An on-screen graphics display provides precise visual recognition of the leak location and identifies the leak rate. The system communicates the information to designated factory communication networks, ensuring the quick resolution of manufacturing deficiencies to avoid downtime and production line backup. In-probe microprocessors initiate data processing while software manages the signals from the multiple sensors. On-board diagnostics maintain system vitals.Cincinnati Test Systems Inc.

(513) 202-5103

www.Cincinnati-test.com

Image acquisition

The PC2-CamLink image acquisition board is a monochrome board designed for the 32-bit PCI bus and the unit supports one Base Camera Link area or linescan camera. Once the camera cables and external triggers are connected, the unit's bracket-mounted visual-status LEDs provide an immediate visual indication that all signals for acquisition and trigger are present and active. These signals validate key data, including camera connection, image captures, occurrence of triggers and reporting of errors. The unit has several trigger interface options, including separate inputs for two optocoupled/TTL and two LVDS triggers, and a dual phase-shaft encoder for linescan applications on two dedicated LVDS inputs that help ensure the accuracy of the acquired image.Coreco Imaging

(514) 333-1301

www.coreco.com

Image management system

The PAX-it Image Management System for acquisition and archiving of digital and analog images is capable of measuring, pre-testing and documenting image data for welding and other applications. The Windows-based operating platform allows for customized tool bars, extensive instructional wizards and an organizational interface for choosing and tailoring user applications. Available in digital and analog configurations, the system also offers a package featuring the high-resolution PAXcam 2.0 MegaPixel Digital Microscope Camera for industrial and scientific applications requiring brightfield, darkfield, polarized light, Nomarski illumination in both reflected or transmitted light, video microscopy and macro applications. Basic or enhanced measurement and image management modules also can be added to the base system.LECO Corp.

(800) 292-6141

www.leco.com

Surface inspection

The Eagle III Vision System inspects 100% of the surface in real time. The location of all defects can be mapped and archived. The system inspects for missing coating, gels, holes, carbon specs, streaks, wrinkles and other surface imperfections. The system can be configured with both basic and advanced classification of the defects. The advanced defect classification software allows the operator to distinguish very similar defects. Streak detection and formation analysis modules are also available.LASOR/Systronics

(770) 449-7776

www.lasor.com

Force and torque gages

A complete line of gages measure any friction, force or pressure for quality control and vital standardization. The units calibrate push/pull, twist, peel forces, or rotational torque required on bottle caps and a myriad of tools. The gages test from 0.5 to more than 4,400 pounds. Features include peak and real-time modes. Motorized test stand systems may be configured with both digital speed indicator and distance meter accessories. All force and torque gages have data output capability.Imada

(800) 373-9989

www.imada.com

Data collection software

Inspect 3.0, visual attribute data collection software, helps reduce costs associated with scrap, re-work, warranty claims and production bottlenecks. The software can be used for collecting, analyzing and reporting defect-related data in applications where part and assembly defect information is critical to the production of quality parts. Visual defect identification and control is as easy as touching the screen. Defects can be found, flagged and a record sent to rework in a matter of seconds. Automated routing for rework is optional. Data is stored in an SQL database, available for immediate access from any Web browser via reporting software. The software also includes a large range of defect reporting tools and an interface to e-mail, paging and other electronic notification tools.ASI DataMyte Inc.

(248) 543-6040

www.datamyte.com

CMM

The Premier series of coordinate measuring machines (CMMs) offers models from 1 meter through 3 meters in travel. Structural components in the bridge assembly are made of carbon fiber. The system is available in 24 sizes with two controller options: the Matrix has the IMS 32-bit On-Motion controller including its Rapid-Scan for touch-trigger operation, and the Maxxum uses the Renishaw UCC series of controllers and supports continuous analog scanning.International Metrology Systems

(401) 667-0109

www.virtual-dmis.com

Dimensional measurement

Sprint CNC 300, an automatic, full-featured dimensional measurement system fits on a benchtop and has a 12-inch by 12-inch XY travel range to accommodate a variety of parts. The unit has a granite base and column with precision mechanical bearing stages and 0.5-micrometer linear scales. Motorized zoom optics, a high-resolution color video camera and programmable illumination sources, including the optional LED VectorLight, ensure image quality. Easy-to-use Basic-X measurement software al-lows users to create and run part programs for fully automatic measurement.RAM Optical Instrumentation Inc.

(480) 505-3506

www.ramoptical.com