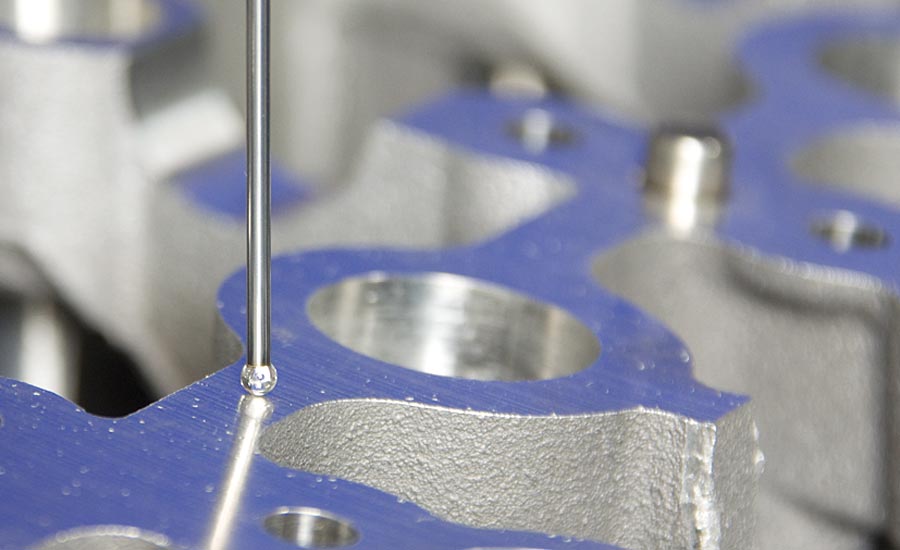

Be it point measurements for exceptional accuracy or the scanning of certain materials, it’s important to have the right stylus system for any measuring task. Many factors influence the selection of different components, which is why there’s no standard solution for people looking for the perfect stylus system. Knowing the basics makes it easier to select the right components in a way that’s matched to each measuring task and environment.

1. The stylus

The stylus is the “tip” of the stylus system and is the first point of contact to the workpiece. Even the construction of the stylus, which comprises the adapter, shaft and stylus tip, impacts the stylus system and thus the measurement result.

Stylus tips

Three factors must be taken into account when choosing a stylus tip: the stylus specifications, and the shape and material of the tip. All features influence each other, which means some stylus shapes are not available in all materials.

Shapes

Ball-tip styli have the widest field of application as they exhibit the same probing behavior in every direction. Note the size of the stylus tip: the bigger it is, the bigger the mechanical filter will be. This means the profile of the workpiece will be smoothed. This is often desirable during form measurement.

Disk styli are used primarily to measure inner and outer cylinders of boreholes, to measure undercuts, and to localize deep grooves and large boreholes. However, this usually results in strong filtering of the surface roughness. As calibration is very complicated and time-consuming, disk styli are rarely used.

Cylinder styli are used for 2D measurements and are especially well suited for narrow workpieces such as thin sheets. Even narrow workpiece edges can be measured using cylinder styli. It is important to ensure that the stylus axis is mechanically and very precisely aligned with the feature axis on the workpiece. Otherwise, you may end up with incorrect measuring results.

Spherical cylinder styli have a field of application similar to that of cylinder styli. The sphere-shaped tip helps determine surface flatness.

Half-sphere styli are well suited for measuring undercuts. They are also used when large sphere diameters are needed for a measuring task. Due to the limit value for the weight of the probe, the spheres are halved and even cut out in the XXT area.

Star styli enable you to probe your workpiece from any direction and are thus frequently used for measuring side surfaces. They measure in four dimensions, meaning they are particularly suitable for measuring boreholes.

Materials

Ruby

The standard for almost all applications. The advantage is that very small spheres can be produced, from a diameter of 0.12 mm and up, however ruby is not as strong as certain other materials when it comes to permanent scanning. With extremely soft materials made of aluminum, for example, workpiece deposits may collect on the ruby surface. However, materials with very hard surfaces will result in wear. The highly precise sphere shape will change and become less accurate.

Steel

Mainly used for disk styli. Diameters up to 100 mm are possible.

Silicon nitride

Suitable for the same applications as ruby-tipped styli. Minimal material deposits are built up when scanning aluminum or other soft materials.

Ceramic

Very light material that is used primarily for large reference sphere diameters (up to 45 mm) and disk styli as well as for scanning rough surfaces. To comply with the limit values of the probe in terms of weight, half-spheres are made of ceramic.

Hard metal

Makes it possible to manufacture styli in special sizes

Diamond

Especially well-suited for measurements on hard surfaces like ceramic or soft aluminum alloys. The sphere will not wear out and soft material will not build up on the surface during scanning.

Diamond coating

Ceramic spheres with a diamond coating have a roundness below

150 nm—which makes them even more precise.

Zirconium oxide

Compared to ruby, this is a rather soft material that is used for styli of manually operated measuring machines.

Stylus specifications

Depending on the measuring task, there may be different specification requirements for the stylus. The mechanical filtration effect must therefore be considered when selecting the sphere diameter. Compared to the fine structures of the workpiece surface, the stylus tip is relatively large and can thus hardly capture the actual surface roughness. The larger the stylus tip, the larger the filter will be. This should be taken into consideration when selecting the sphere size and, if necessary, a smaller sphere should be selected.

Stylus shafts and their setup

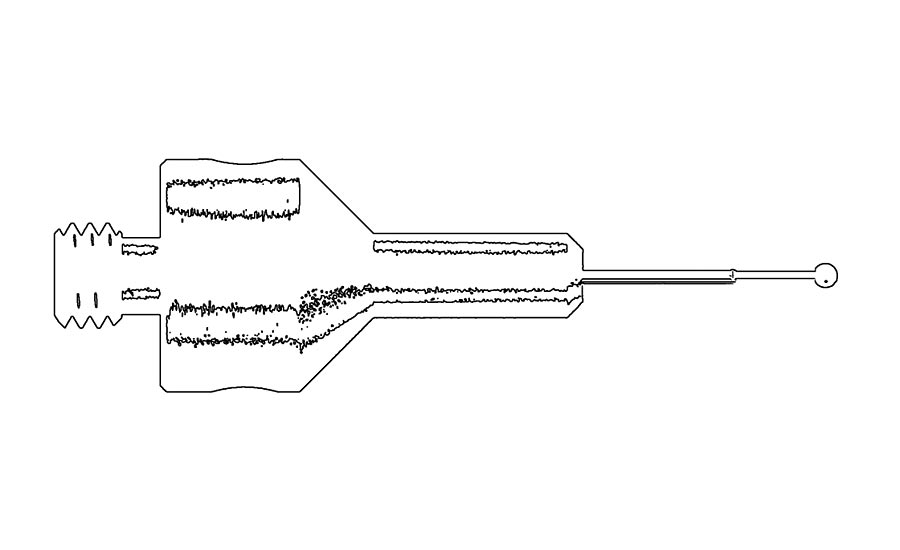

There are two types of stylus structures: with a stepped or straight shaft.

Stepped shaft image

Stepped shafts have the advantage that the shaft diameter is reduced at the stylus tip and thus help achieve better flexural strength. The drawback is the small usable measurement range.

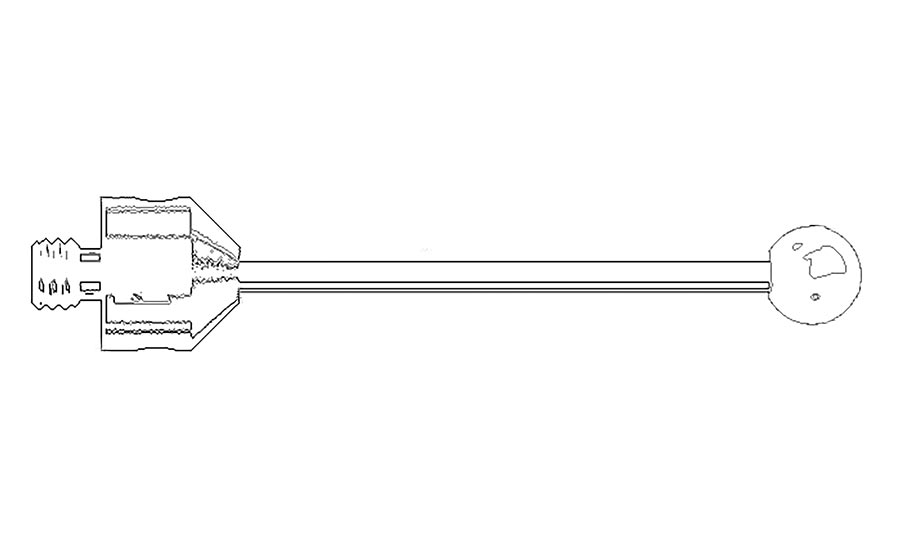

Straight shaft image

Styli with a straight shaft have a larger measurement length and thus a larger measurement range. It is therefore sometimes necessary to use straight styli to reach all points.

The stylus shaft material

When selecting a shaft material, you need a perfect balance between rigidity, weight and thermal linear expansion. The stylus rigidity is influenced by the choice of material and by the cross section of the shaft. Shafts made of solid material are more rigid than those made of tubes.

2. Connecting elements

Constructing stylus systems

There are a range of different connecting elements for constructing stylus systems. These can be fixed cubes, angle pieces or end angles.

The standard connecting element is the cube as it allows attachment of several styli in different directions. But there are also freely adjustable rotary elements that enable rotation around the longitudinal axis and support the backlash-free angular adjustment of the stylus system. This means any angle can be set. There are many ways of combining elements. Please observe the following:

A stylus system should have as few connecting elements as possible as every interface, especially in batch measurement mode, can loosen. This can lead to a loss in rigidity. It is preferable to combine several elements in a single element, such as an extension and a cube, when possible.

Moveable elements like knuckle joints increase the flexibility of a stylus system. In contrast to set angle pieces, any angle can be set repeatedly with the knuckle joint. An integrated cone receiver also enables the rotary setting of space angles. This ensures the stylus system remains flexible.

Combining connecting elements that become thinner as they move to the stylus are more rigid and more stable.

For batch measurement mode, fixed connections like milled angle pieces are preferable because the angles do not shift during continuous operation.

3. Extensions

General Properties

As a rule, all extensions should be as rigid and light as possible.

Extensions help set up complex stylus systems. They enable the setup of long styli to measure hard-to-reach features on a workpiece. Extensions can also be connected directly on the adapter plate to construct the stylus system in z direction. Both extension options support the construction of complex system configurations, which reduces the number of stylus changes.

The selection of suitable stylus and plate extensions is based on the permissible weight, rigidity and thermal stability requirements. Please also bear in mind the guiding principle “thickest to thinnest.” This means the most rigid extension should always be selected for the adapter plate, i.e. a thick one. Thin extensions are only recommended once accessibility close to the workpiece becomes important.

Scanning speed

To achieve the highest possible scanning speed with low form error, select extensions with a large diameter, low weight and high rigidity.

Aluminum

is relatively light. With a thermal expansion coefficient of 23.4 µm / °C / m, the material is thermally unstable. Such extensions should only be used in well-climatized measuring labs.

Titanium

is very light. Compared to aluminum, titanium extensions have higher rigidity and lower thermal expansion. The extensions should only be used in well-climatized measuring labs

Stainless steel

has a high weight and a very high thermal expansion coefficient of 16.0 µm / °C / m. Such extensions should only be used in well-climatized measuring labs.

4. Adapter plates

Adapter plates are the central interface between stylus and measuring machine. They are selected to match a particular stylus. Adapter plates from different providers differ only in terms of functions and quality.

Conclusion

The perfect stylus system always depends on the measuring task at hand.

A rule of thumb is: A good stylus system has few joints, is as rigid and temperature-resistant as possible and weighs as little as possible. It’s important that the stylus system can record all probing points safely. Many sensors also have strict requirements in terms of the weight and length of the stylus system. Some of them can only bear stylus systems that weigh up to 15 g. In that case, ensure you use materials that are as light as possible. What’s more, the weight should be distributed as evenly as possibly as the limit values of the pull-out torque must not be exceeded. Selecting the right stylus system is an easy way to reduce the measuring time. Constructing complex stylus systems reduces the number of styli and systems you need. This means fewer stylus changes, which saves a lot of time and therefore money, too. Q